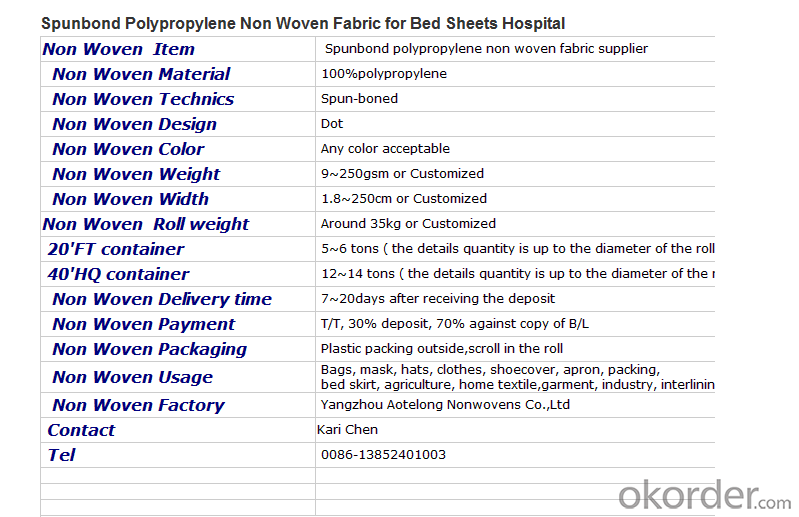

Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

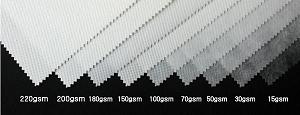

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Antistatic fabrics of textile electrostatic materials

- Static electricity is serious, the static voltage up to several thousand volts, due to discharge sparks, causing a fire, causing serious consequences.

- Q: Cotton chemical fiber textile, hemp textile, wool textile, silk silk textile industry, the difference between the four

- From 2000 to this year, the national cotton acreage, yield and cotton market supply and demand relationship, the rapid development of China's cotton industry, from the cultivation of surface cross, production and enterprise scale have unprecedented unprecedented development, but also to the textile industry development into power, Promote China's textile industry into a new period of development, the international competitiveness increased significantly

- Q: What is the purpose of using detergent in the textile industry?

- Textiles in the storage and transportation process is also easy to stained debris, dust and other impurities, but also to remove the dye.

- Q: What is the step in the textile fabric

- With the words and deeds, the attitude represents the company, so with the business units to deal with the corresponding business process, we must grasp the basic principles, pay attention to words and deeds, attitude neither overbearing nor humble. It is strictly forbidden to have any excitement to the client (or the customer's merchandiser) for any subjective or objective reasons. Processing business process can not arbitrarily overweight position, there are problems in time to ask the company to decide.

- Q: Textile enterprises to operate the project: processing and production are different?

- And production from the beginning of raw materials, such as from the thread to the weaving, made of cloth and then made into clothes.

- Q: What is a large circular machine and a small circular machine in the textile?

- First, the circular machine and the small round machine is based on the weaving plant to produce the width of the fabric to determine, not according to its price and the quality of the fabric produced by the request.

- Q: China is now optimistic about which one of the textile industry

- Special decorative textiles industry multi-functional high-level tent materials, automotive lightweight cover and interior materials, membrane structure materials and other special decorative textiles processing technology and industrial applications.

- Q: What is the specialty of textile science and engineering?

- Textile science and engineering disciplines covering textile engineering, textile materials and textile design, textile chemistry and dyeing and finishing and other disciplines

- Q: What are the products produced by the textile mill?

- Or weaving from the weaving method: knitting, woven, non-woven fabric. For example, we wear the T-shirt is knitted. Woven, such as shirts, jeans and so on. Non-woven fabrics, such as the suit inside the lining, we are now the most popular shopping bags. They are nonwovens.

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Lining the general requirements of the hot melt adhesive is colorless and tasteless, soft texture, fast bonding, resistance to dry and wet wash, glue can not affect the fabric, resistant to light and so on. Various types of hot melt adhesives can be used with a wide range of hot melt adhesives. Most of them are ethylene-vinyl acetate (EVA) hot melt adhesives, polyamide hot melt adhesives and high pressure polyethylene (HDPE) heat Melt powder, and different uses of hot melt adhesive and processing methods are also different.

Send your message to us

Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords