PP/HDPE One-Way Plastic Geogrids for Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

One-Way Plastic Geogrid Products

Products overview:

Unidirectional geogrid is made of polymer by extrusion pressure into sheet rules of mesh again, then the longitudinal tensile and into. The directional linear polymer into state and in the process of uniform distribution, long oval mesh nodes with high intensity is the structure integrity. This kind of structure has a very high tensile strength and tensile modulus, especially my company this kind of product is more than the international level of high early (elongation at 2% to 2%), tensile strength and tensile modulus. To the soil provides ideal assumption of the force and the spread of the chain system, the product tensile strength (> 150 mpa), adapt to all kinds of soil, is currently widely used reinforcement reinforcement material.

Product features:

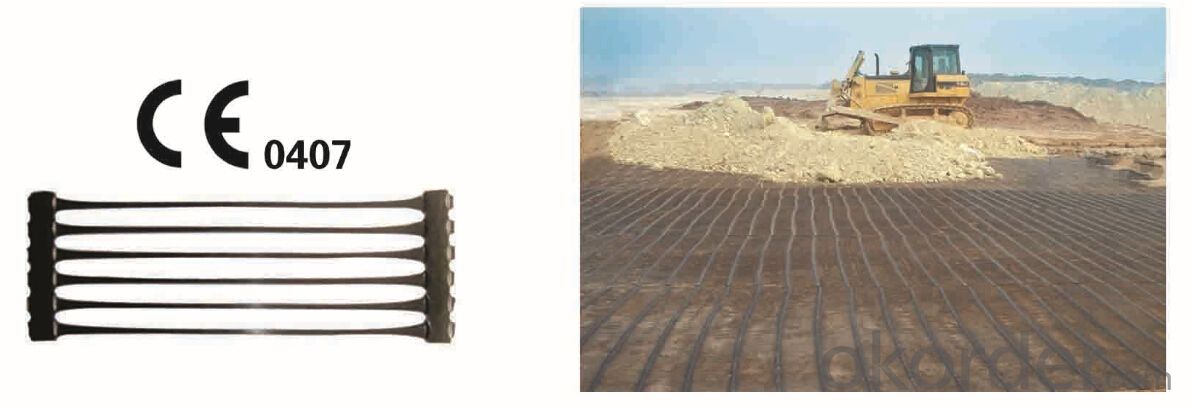

1, strengthen roadbed, can effectively allocate diffusion load, improve the stability and bearing capacity of subgrade, prolong service life.

2, can withstand greater alternating load;

3, prevent subgrade material loss caused by the embankment, cracking;

4, make the file after the wall of the filled soil bearing capacity increase, reduce the pressure of the retaining wall, save costs and prolong service life, and reduce maintenance costs;

5, spray anchor concrete construction method for slope maintenance, not only can save 30% - 50% of the investment, but also can shorten the time limit for a project more than double;

6, adding geogrid in highway roadbed and road surface, reduces the deflection, reduce furrow, delay cracking 3 to 9 times, structure layer thickness can be reduced by 36%;

7, used in a variety of soil, no need different materials, save work time;

8, easy construction, can greatly reduce the construction cost.

Product application:

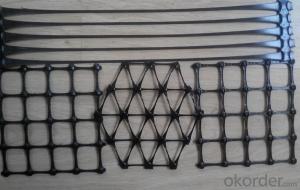

1, mainly used for retaining wall, abutment, steep slope engineering, etc.;

2, retaining wall and the abutment belongs to the mechanical structure, all bear the external loads, the active earth pressure, the upper structure of the load, temperature stress, such as reinforced material under great tension for a long time, and again and again under the action of dynamic load, the molecular structure of the material to produce fatigue, its performance attenuation, accelerate the ageing of the grille, to avoid structure due to the creep in reinforcement material and produce large deformation, should choose to unidirectional geogrid of high-density polyethylene as raw material.

Product specifications:

TGDG35 TGDG50 TGDG80 TGDG110 TGDG120

- Q: How do geogrids improve the performance of mechanically stabilized slopes?

- Geogrids improve the performance of mechanically stabilized slopes by providing reinforcement and stability to the soil. They distribute the stress and load more evenly, reducing the potential for slope failure or movement. Additionally, geogrids increase the overall strength and integrity of the slope, allowing for steeper slopes to be constructed.

- Q: What is the main purpose of unidirectional plastic geogrid?Plastic geogrid production

- Unidirectional geogrid use:For strengthening soft foundation: Geogrid can rapidly improve the bearing capacity of the foundation and development of settlement control, can effectively load to the base of a wider upper limit on the road side, thereby reducing the base thickness, reduce project cost, shorten the construction period, and prolong the service life of

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

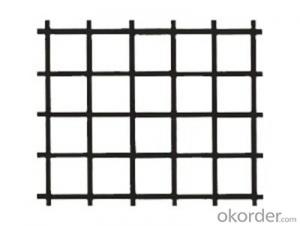

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid. Engineering applications: highway, railway, bridge, road, pier, dam, slag field, such as soft soil foundation reinforcement, retaining wall and pavement crack resistance engineering and other fields.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are generally resistant to high temperatures. They are designed to withstand extreme temperature variations without losing their structural integrity or performance.

- Q: How do geogrids improve the performance of geosynthetic filters?

- Geogrids improve the performance of geosynthetic filters by providing additional reinforcement and stability to the filter system. They enhance the tensile strength and load distribution capabilities of the filter, preventing soil erosion and maintaining the integrity of the filtration system. Additionally, geogrids help to reduce pore clogging and increase the overall longevity and efficiency of the geosynthetic filter.

- Q: Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids are commonly utilized in civil engineering projects to improve the stability and strength of soil structures. By incorporating geogrids into rail embankments and cuttings, the soil is effectively reinforced, preventing erosion, reducing settlement, and enhancing overall stability. This reinforcement technique helps to ensure the longevity and safety of rail infrastructure.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

- Q: Can geogrids be used in bridge abutments and approach embankments?

- Yes, geogrids can be used in bridge abutments and approach embankments. Geogrids are often employed in these structures to enhance soil stability, reinforce the embankment, and provide additional support to the bridge. By distributing loads more evenly and reducing lateral movement, geogrids can help improve the overall performance and longevity of the abutments and embankments.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials with high tensile strength, used in civil engineering and construction projects. They are typically made from polymers such as polyester or polypropylene and have a grid-like structure. The properties and characteristics of geogrids include: 1. Tensile Strength: Geogrids possess high tensile strength, allowing them to withstand heavy loads and distribute stress efficiently. This property makes them suitable for applications such as soil stabilization and reinforcement. 2. Aperture Size: Geogrids have a grid-like structure with different aperture sizes, which can vary based on the intended use. The aperture size determines the amount of soil interlock and confinement provided by the geogrid. 3. Flexibility: Geogrids exhibit flexibility, enabling them to conform to the shape of the terrain or structure they are applied to. This flexibility allows for easier installation and adaptability to different project requirements. 4. Durability: Geogrids are designed to be highly durable and resistant to environmental conditions such as ultraviolet (UV) radiation, chemical exposure, and biological degradation. This durability ensures the long-term performance and lifespan of geogrids in various applications. 5. Installation Ease: Geogrids are generally lightweight and easy to handle, facilitating their installation. They can be rolled out or placed directly onto the ground, minimizing the time and effort required for construction. 6. Soil Interaction: Geogrids enhance the interaction between soil particles, increasing their shear resistance and improving overall stability. This property is especially beneficial in applications like retaining walls, slopes, and roadways. 7. Drainage Capability: Some geogrids have a porous structure that allows for water drainage, preventing the buildup of hydrostatic pressure and reducing the risk of soil erosion. Overall, geogrids offer a range of beneficial properties and characteristics that make them versatile and effective in various civil engineering and construction applications.

Send your message to us

PP/HDPE One-Way Plastic Geogrids for Asphalt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords