Poplar and Hardwood Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Poplar and Hardwood Core Film Faced Plywood

Product Description:

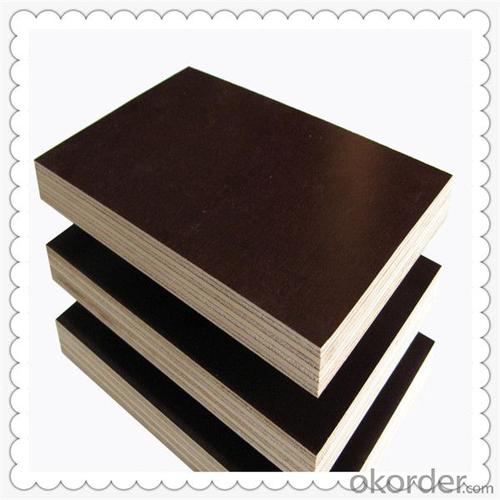

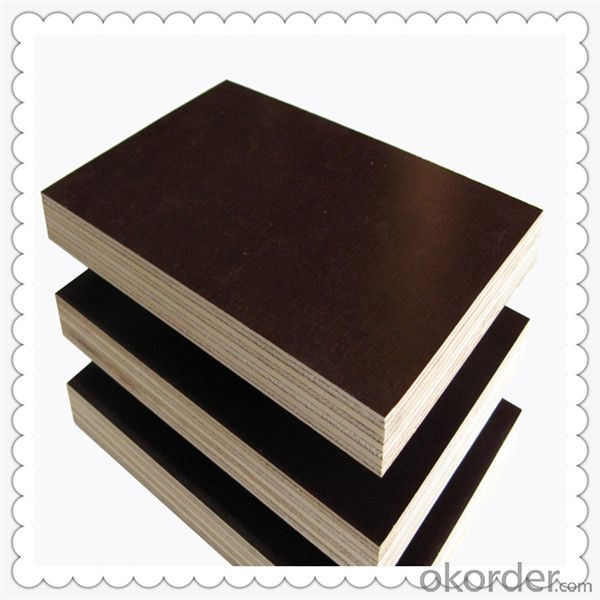

· Type: Film Faced Plywood

· Material: Wood

· Wood Style: Panel

· Panel Type: Plywood

· Use: outdoor

· Place of Origin: China (Mainland)

· Model Number: 1220x2440mm

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

Packaging & Delivery:

1. Packaging Details: inner packing:0.20mm plastic bag; outer packing: pallets are covered with plywood or carton and then steel for strength

2. Delivery Detail: within 15 days after receiving the deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

As of the end of 2000, CNBM has 492 member companies under management around the world, of which 5 were A-share listed holding companies and 2 were H-share listed. CNBM has total assets exceeded RMB 110 billion, and more than 100,000 employees.

CNBM is the largest comprehensive building material industrial group in China that integrates scientific research, manufacturing and logistics into one entity.

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- Not prefabricated, is custom production.

- Q: What is the current project wall, which kind of roof? There are commonly used models

- General factory roof do mineral wool, sandwich tile seems to be through the fire, the wall is generally used a single layer of tile

- Q: What is the difference between handmade rock wool sandwich panels and mechanism sandwich panels?

- As the name suggests, the inner layer is a foam board, thermal insulation but not set fire. The other is rock wool, thermal insulation, fire!

- Q: 100 thick composite sandwich board how much money a square meter upper plate 0.6 lower 0.4

- More than sixty yuan / square meters ---- ordinary materials.

- Q: Fuhan 18mmE0 grade sandwich panels how?

- Now are generally E1-class wood core board, and E1 grade Fuhan plate genuine goods, then environmental protection is the standard. E0 level of rare, and expensive

- Q: 100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: With the production of sandwich panels can now control how many years?

- In general, sandwich panel covers the house! On the iron thickness of 0.4, under the thickness of 0.326, you can protect the new 10 years, no later than 2 years spray a paint, up to 25 years! Aluminized zinc is longer,

- Q: Color steel 50 mm rock wool sandwich board one meter how much the price

- It is not normal to say that there is a flat between 40 and 50

- Q: Color steel sandwich board board how to deal with bump

- After forming the basic no way, only to improve the process to solve

Send your message to us

Poplar and Hardwood Core Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords