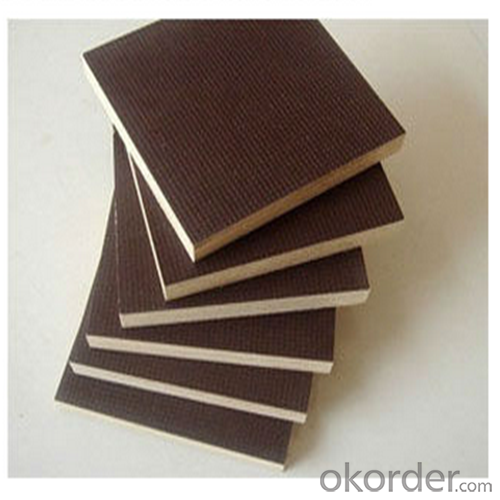

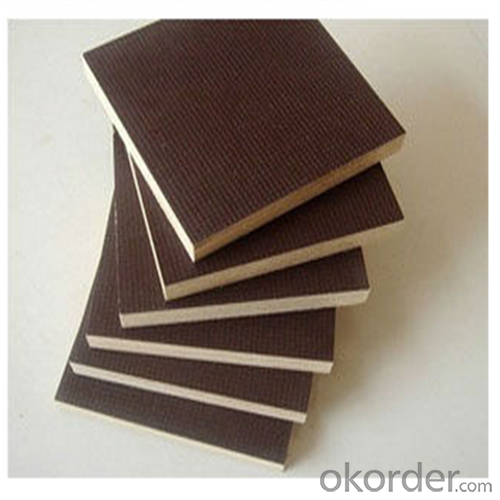

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description:

Place of origin: Shandong China

Face&back: Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested

Core: Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement.

Size: 1220*2440/1250*2500mm and as your requirement

Thickness: 2mm to 30mm and as for your requirement

1/8 inch(2.7-3.6mm)

1/4 inch(6-6.5mm)

1/2 inch(12-12.7mm)

5/8 inch(15-16mm)

3/4 inch(18-19mm)

Thickness tolerance: 2-6mm: +/-0.2mm; 6-30mm: +/-0.3mm

Grade: BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc.

Glue: MR,E1,E2,Melamine,WBP Phenolic

Moisture: 10%-15%

Joint way: Overlap joint, end joint, scraf joint, finger joint

Strength: High bending strength Strong nail holding

Quantity: 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ

Usage: construction, Furniture, decoration, packing.

Certificate: ISO9001: 2000; CE; CARB

Main market: Middle East, South Asia, South America, Africa

Shipment & payment:

MOQ: One container

Port: Qingdao Port, China

Packing details:

Inner packing: 0.2mm thick plastic bag

Outer packing: pallets covered with plywood/carton, then steel taped for strength

Delivery time: 2 weeks after your deposit

Payment: T/T, 30% deposit, the balance against the copy of B/L, L/C at sight.

Advantage:

Capacity: 6000 CBM per month

Can supply samples

High quality and competitive price

Over 30 years’ experiences in export

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Rock wool sandwich board Yanmian generally what brand, quality Zeyang?

- We are all with a small factory rock wool, we do not know the manufacturers, but this thing is too much pollution

- Q: What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q: EPS corrugated composite board and corrugated sandwich board What is the difference, 50MMEPS corrugated composite board (0.5 on the next 0.4) to do the plant roof construction process is how The price is almost a square?

- EPS corrugated composite board is a corrugated sandwich board, according to the core of the different corrugated sandwich panels are divided into EPS corrugated sandwich panels (that is, EPS), extruded sandwich panels, polyurethane sandwich panels and rock wool sandwich Plate and so on. Construction is the steel structure plus sandwich panels.

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: I would like to ask the color steel tile sandwich panels can cover the chicken coop? Does it have a good insulation effect?

- Can be, but the traditional ceiling color steel tile sandwich panels generally composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K ) Above, plus foam and foam board between the gap, the temperature is very serious, comprehensive actual thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because the polyurethane in the construction of the use of direct spray molding technology, so that the polyurethane foam layer without patchwork as a whole to form a complete impermeability, fundamentally put an end to the possibility of deep water along the seam along the seam. Which play a preservative and waterproof effect.

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- Yes, bagging it will prevent tripping the alarm unless it is a tamperproof model. I used to install fire protection systems in hospitals and schools and we would put a baggie with a string attached to each detector so they did not trip from dust and welding smoke during copnstruction operations. Once the job was complete and the building was cleaned up we would walk through and pull off the plastic. Wrap a rubber band around the baggie so it stays snug. You can also avoid the tripping by opening a window near the stove and putting a fan in it as well as turning on the stove exhaust fan if you have one.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

- Q: What are the key notes when buying a rock wool sandwich panel?

- There are four key factors: 1. Look at the use of construction: long-term construction or plant application of high quality (rock wool density is equal to 120kg / m3, the outer steel thickness is equal to 0.7mm, thickness of 100mm or more) of the rock wool sandwich panels, because the simple rock Cotton sandwich board after the installation of the surface easy to arch, bubble 2. Flatness: the requirements of the facade of the high demand, the use of mirror flat cotton wool sandwich panels, mirror flat cotton wool sandwich panels than the production of ripples difficult 3. Fire resistance: rock wool board production process should pay attention to the mouth and the mother of the filler, filled with rock wool board fire performance, filled with polyurethane and other materials, poor fire performance 4. Gongkou and the mother after the joint, the horizontal joints at the level of high and low error, high-quality quality rock wool board error is very small, low-end products will be interested in the horizontal slit to 10mm desalination level difference.

- Q: Use the foam color steel sandwich panel after decoration

- Paste the wallpaper, polystyrene foam board - also known as foam color steel sandwich panels, EPS board is containing volatile liquid blowing agent of the polystyrene beads, heated by heating in the mold after heating It is mainly used in building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, decorative carving and other uses are very extensive. Wallpaper, also known as wallpaper, wall cloth, is a wall for the interior decoration materials, widely used in residential, office, hotels, hotel interior decoration. Material is not limited to paper, but also contains other materials. Because of the colorful, rich patterns, luxurious style, safety and environmental protection, construction convenience, affordable and other kinds of other interior materials can not match the characteristics, so in Europe and the United States, Japan and other developed countries and regions have been a considerable degree of popularity. Wallpaper is divided into many categories, such as film wallpaper, coated wallpaper, embossed wallpaper and so on. Usually with bleached chemical pulp production of base paper, and then by different processes of processing, such as coating, printing, embossing or surface coating, and finally by cutting, packaging after the factory. Has a certain strength, toughness, beautiful appearance and good water resistance.

- Q: The steel roof and the sandwich panel are waterproof

- The two are actually the same class of things, sandwich panels only the color plate and insulation layer together, the installation more convenient. And the pressure steel roof need to lay another insulation layer and the roof. For both, the weak links of water are between the plates. In the actual project, the seam of the steel plate roof can be made in many forms, some of the overlapping form of waterproof performance is very good, and the common sandwich board roof shape is relatively simple, so the waterproof performance is also worse.

Send your message to us

Poplar and Combi Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords