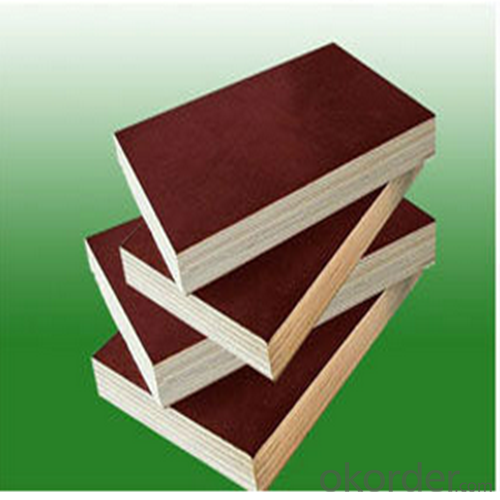

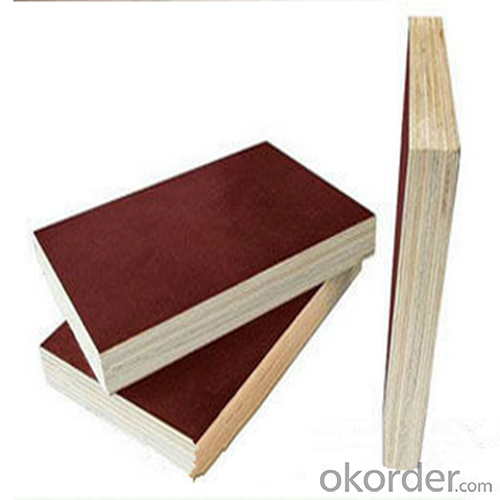

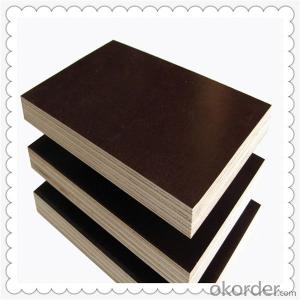

Brown Color Poplar Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

· Type: Plywoods

· Model Number: FFP-01

· Usage: Outdoor, construction

· Grade: First-Class

· Main Material: Poplar, Combi

· Formaldehyde Emission Standards: E1

· Plywood Type: 3,4,5,7,9,11,13,15,17,18 Ply boards etc

· Face/back: black/brown/red film, anti-slip etc.

· Glue: WBP, MR, melamine

· Core: poplar, combi

· Size: 1220X2440MM/1250X2500MM

· Thickness: 9mm~30mm

· Certification: ISO9001: 2008; CE; CARB

· Market: Middle East, South Asia, South America, Africa

Packaging & Delivery

Packaging Details: | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength |

Delivery Detail: | 2 weeks after 30% deposit or L/C |

Specifications

Detailed Product Description | ||

Place of origin | Shandong China | |

Face&back | Black film, brown film, red film, anti-slip film | |

Core | Poplar, Combi, Birch, eucalypts | |

Size | 1220*2440/1250*2500mm and as your requirement | |

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) |

1/4 inch(6-6.5mm) | ||

1/2 inch(12-12.7mm) | ||

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 2-6mm: +/-0.2mm | |

6-30mm: +/-0.3mm | ||

Grade | first class | |

Glue | MR,Melamine,WBP Phenolic | |

Moisture | ≤12% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction, Furniture, decoration, packing. | |

Certificate | ISO9001: 2000; CE; CARB | |

Main market | Middle East, South Asia, South America, Africa | |

Shipment & payment | ||

MOQ | One container | |

Port | Qingdao | |

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | |

Delivery time | 2 weeks after your deposit | |

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | |

Advantage | ||

Capacity: 8000 CBM per month | ||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Color steel foam sandwich board is how much? Model is divided into several?

- There are two types of panels: Metal panel and non-metal panel two. Metal panels are easy to process and can be made in a variety of shapes, but in some cases non-metallic panels have the effect of metal panels, such as corrosion resistance, impact resistance and so on. Widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities room, building plus layer, clean workshop and the need to heat insulation fire places. Sandwich board shape beautiful, bright color, the overall effect is good, it sets load, insulation, fire, waterproof in one, and no secondary decoration, quick and easy installation, short construction period, comprehensive benefits, is a wide range of uses, With the potential of efficient and environmentally friendly building materials.

- Q: Is the sandwich panel toxic? Now we live with a sandwich board to do the house, listen to friends that sandwich board toxic, is it true?

- Sandwich panels are environmentally friendly materials, how many are a bit, no big problem, you can rest assured that use. But I would like to remind is in the color of the steel house, pay attention to the improper use of the kitchen to prevent fire. For the quality of sandwich panels, the world color steel is good to understand the next.

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: Domestic manufacturers of rock wool sandwich panel machine which quality is better? What is the price in general?

- My company is using OKorder Yongming, spent more than six years. I personally feel that quality can be. My friend is using the other manufacturers in OKorder, you can also use, the domestic manufacturers in OKorder is doing a little better. As for the price, a price of a cargo, the landlord can visit more, the domestic production of such equipment manufacturers concentrated in OKorder and Hebei.

- Q: 100 thick rock wool sandwich panels (1.1 meters from the purlin) can do the roof? Floor thickness 0.8, panel thickness 1, so feasible?

- It is recommended to use pressure plate, flat or defective.

- Q: Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q: Color steel sandwich panel prices

- Foam board 10 kg 0.4 iron 60 yuan up and down. Polyurethane 160 to 220 yuan

- Q: 50mm thick insulation color steel sandwich board with J * B42-333 * 1000 What does this mean?

- It may be said that the sandwich board wave height 42 wave width 333 width 1000 bar Oh country mark should not be so that the specification model

- Q: OKorder where to sell rock wool color plate, rock wool sandwich panels and good quality?

- OKorder multi-dimensional joint light steel sheet of the good, mostly for the project.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

Send your message to us

Brown Color Poplar Material Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords