Polyurethane Foam Sandwich Panels - Color Steel PU Laminboard

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | export standard seaworth package,or as per costomer request |

| Delivery Detail: | within 15 days after receive your prepayment |

Specifications

EPS sandwich panel

1.width:950-1000mm,

2.density:30-50kg/m3

3.thickness:50-200mm

4.MOQ:100squire meters

Cheat Sheet

Effective width | Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm |

Length | According to customer' s request |

materials | Polystyrene foam board(EPS), Color steel sheet,Rock wool |

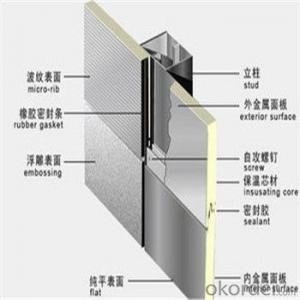

Structure | Upper and lower layer: Color steel sheet |

Middle: polystyrene foam board or polyurethane foam board or rock wool | |

Thickness | Color steel sheet: 0.3-0.6mm |

density | Rock wool 120-250kg/m3 EPS 12-35kg/m3 |

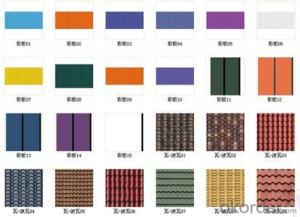

Conventional color | Ocean blue, tephrosious and other RAL color |

lifetime | 15~20 years |

Character | Light in weight, heat insulation, water resistant, green and environmental |

Use | various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc. |

Detailed Information

1.Product Description

Heat Insulation / Inflaming Retarding

Thickness: 50mm-200mm

Width: 950mm/1150mm

Steel Thickness: 0.35mm-0.80mm

Color: As request

This kind of Sandwich Panel has many features as follows:

2.Material:

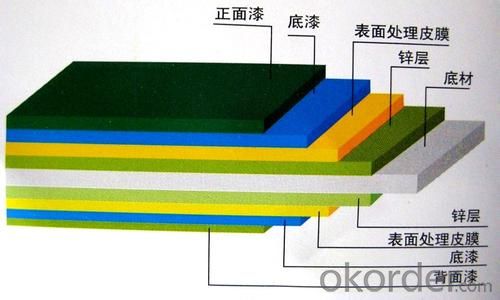

1. The thickness of up/lower steel panel: 0.35-1.2mm colour-coated panel/zinc plate, hot galvanized plate/stainless steel panel

2. Core material---The density of this(mineral)

Rock wool is: 120-250kg/m3

3. Side steel strip or not: 0.35-0.8mm galvanized plate

3.Specification:

1. The suitable interface width: 950mm, 1150mm

Thickness: 40mm-300mm

Length: No limit

2. Surface protection: PVC foil

Characteristics:

1. Advantage: Good fire-resistance, noise-absorbing

2. Fire resistance raring: None

4.Usage:

1)This kind of sandwich panel can be used in large industrial plants,warehouses

supermarkets, hospitals, stadiums, cold storage, activities room, buildings plus layer,

clean workshop and heat insulation fire place.2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office, warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight construction materials

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- If it is added foam cement insulation board, just add a bubble device, the principle of insulation is the air bubble to reduce heat conduction. Foam plastic cement insulation pedal brother Xi Jiadian tripod end plate is added EPS polystyrene foam, insulation principle is polystyrene foam to reduce heat conduction.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: What is the difference between the board and the core board? The The

- Cantilevered scaffolding should use biaxial symmetrical section of the steel, which is usually said I-beam models and anchors need to calculate each other, according to the stairs to set the shape

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are widely used in the construction industry for their durability, insulation properties, and ease of installation. These panels consist of two outer layers, typically made of metal, and a core material, such as polyurethane foam or rockwool, providing excellent thermal insulation. Food kiosks require a hygienic and clean environment to comply with food safety regulations. Sandwich panels offer a smooth, non-porous surface that is easy to clean and maintain, making them ideal for food kiosks. The panels also provide thermal insulation, keeping the interior cool or warm depending on the climate, which is crucial for storing and serving food at the right temperature. Additionally, sandwich panels are lightweight, which makes them easy to transport and assemble, allowing for quick setup and relocation if needed. They are also structurally strong, providing stability and security for the kiosk. Overall, sandwich panels are a suitable choice for food kiosks due to their durability, insulation properties, hygienic surfaces, and ease of installation.

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: What are the different types and uses of clean color steel plates?

- Playing glass glue, with a little better quality.

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Door scaffolding, fastener steel scaffolding, bowl button steel pipe scaffolding, socket-type steel scaffolding. It is best to pay for the work of the scaffolding to learn the preparation of scaffolding program

Send your message to us

Polyurethane Foam Sandwich Panels - Color Steel PU Laminboard

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords