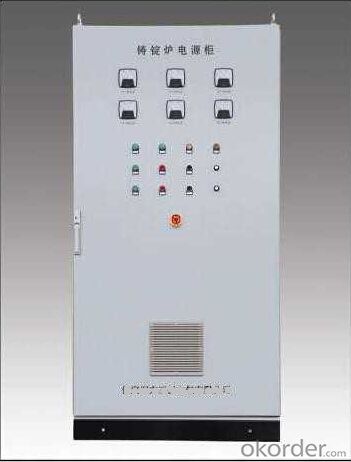

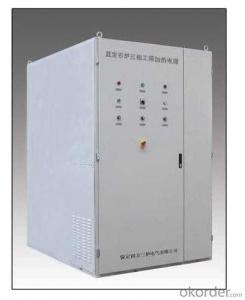

Polysilicon ingot Furnace Heating Power Supply

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

Polysilicon ingot furnace heating power supply plays an important role in polysilicon ingot furnace heating system to provide electricity for crystal ingot casting process and it ensures that the furnace can work under the rated temperature. The power supply can control ingot furnace heater temperature of the upper and lower layer respectively, and it is with merits of high control precision, flexible control and smaller current shock to the power grid.

Product Principle

Combining with the control concept of current international mainstream, the heating power supply adopts the digital design to make the machine run more efficiently, and the on line function can reduce the impact on power grid.

Technical Features

1. Flexible operation and convenient maintenance: It installs LCD (Liquid Crystal Display) monitor panel and displays operation parameters in real time. The control parameters can be modified online and fault information can be automatically recorded, etc.

2. High control accuracy and good stablity: It adopts phase-locked loop synchronous circuit and digital trigger. On sampling algorithm of the load characteristics, it has multiple software protection function. The power devices and circuit breaker etc. adopt international and domestic famous brands.

3. Advanced processing technology of transformer: Transformer adopts high-low pressure complete foil coil winding, step laminated and damping measures. It is with merits of low noise and loss, light weight with small volume, and saving installation space. It has strong heat dissipation ability to achieve 20% overload running stably under the condition of forced air cooling.

4. Double roads of output power: Two lines of output power can work in following mode or in alternate mode, which makes it easy for users to better control the output power.

5. Higher power factor and less current distortion.

Main Technical Parameters

| AC Input | Input voltage | AC380V 土 10% |

| Input current | 300A | |

| Working frequency | 50/60Hz±5% | |

| AC Output | Output Voltage | AC 0-50V |

| Output current | AC 0-4500A | |

| Output power accuracy | 1% | |

| Overload capacity | Long-time running with 110% rated current | |

| Main characteristics | Work mode | CP |

| Efficiency | 98% | |

| Power factor | 0.98 | |

| Communication Interface | Profibua-DP, RS485, RS232 | |

| Operation Display | LCD Monitoring panel; Operational parameters setting; Multiple parameters display | |

| Type of cooling | (F),Wind cooling | |

| Output mode | Voltage regulation or power regulation | |

| Protection | Input phase-deficient | Input A、B、C three - phase Jose phase cause stop |

| Output overvoltage、over current | Over threshold cause stop | |

Three-phase current imbalance alarm | Auto-stop when higher than setting value | |

| Power component overheating alarm | Alarm and stop when higher than setting value | |

| Feedback signal disconnect alarm | Auto-stop when detection of feedback signal fail | |

| Working environment | Ambient humidity | 0 - 85% No condensation |

| Altitude | ≤1200m | |

| Dimension | <H x W x D) Control cabinet | 2200 x 800 x 600mm |

| (H x W x D> Transformer cabinet | 1420 x1270 x900mm | |

| Remarks | Allow design and production according to customer’s request | |

- Q: What is the frequency of industrial electricity in the Philippines?

- Frequency, is the unit time to complete the number of cyclical changes, is to describe the amount of periodic movement frequency, commonly used symbols f or u said, in units of seconds. In order to commemorate the German physicist Hertz's contribution, people put the frequency of the unit named Hertz, referred to as "He". Each object has an amplitude independent of its own nature, called the natural frequency. The concept of frequency is not only used in mechanics, acoustics, but also in electromagnetics and radio technology.

- Q: EPS emergency power supply and DC screen is one thing, what is the difference between the two?

- Mainly used in road traffic lighting, venue lighting, building fire escape lighting, fire pumps, spray pumps and other fire equipment to provide emergency power supply, EPS fire emergency power supply through the CCC China national compulsory product certification, the current state through the 3C certified EPS Fire emergency power supply size is 0.5KVA to 110KVA. EPS fire emergency power supply can be divided into emergency lighting, hybrid and power inverter EPS emergency power supply three categories.

- Q: Do you want to use the DC24V of the alarm system for the power cord of the bus-specific fire-fighting telephone?

- 2, when the current use of fire telephone module access, the module itself needs to provide DC24V power supply, power supply by the fire alarm controller output power bus. The fire telephone module, respectively, access to the power bus, telephone bus (fire phone controller output), and output two bus access to the phone jack and telephone extension.

- Q: PIC microcontroller used in the industrial field, the power supply using switching power supply plus B0505 isolation module, anti-jamming performance is better

- Certainly better, or else else to develop this power module why? All with a direct switch power supply! The

- Q: Meizu special mobile power is which brand?

- Meizu official did not move the power supply products, but before iWALK brand is designed for Meizu out of a 2500 mAh white mobile power, you can go to Jingdong Mall search.

- Q: Apple 4s dedicated mobile power are what?

- 4, select the point of attention: 1) look at batteries, 2) to see the conversion rate, 3) look at materials, 4) to see the mobile power brand,

- Q: Why do you need to use isolated power in industrial communications?

- In simple terms, the need for isolation mainly involves: communication equipment on the power of the stability and anti-interference requirements are high,

- Q: Industrial power cabinet generally use what brand of power

- 3.APC, the old brand, was EMERSON acquisition, but the market share and then gradually reduced.

- Q: Industrial UPS power supply how to choose?

- Ren of UPS power supply, has been successfully applied to more than 300 factory-level customers, is committed to the factory-class customers with a full range of power and energy solutions, any of the UPS power supply, stable performance, first-class quality, each UPS power factory To go through at least 40 tests to ensure that the product is absolutely stable to reach the hands of customers, any of the UPS power supply, factory UPS power solutions for the best partners.

- Q: Driving recorder dedicated power box for what use

- 1) Driving recorder is through the recorder comes with the adapter plug in the car cigarette lighter interface, the use of the process of driving; 2) After the recorder to be charged to charge, then connected to a USB port with a USB or USB charger on the charge can be;

Send your message to us

Polysilicon ingot Furnace Heating Power Supply

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords