Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

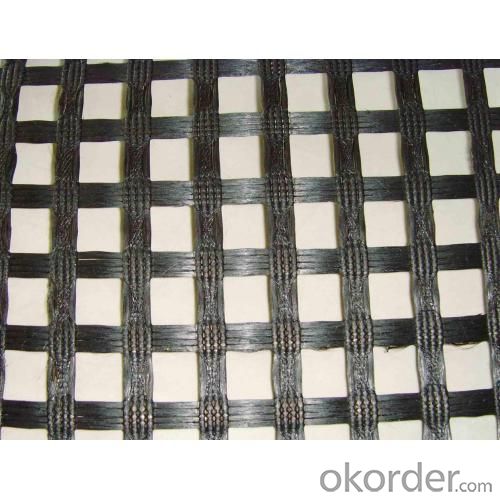

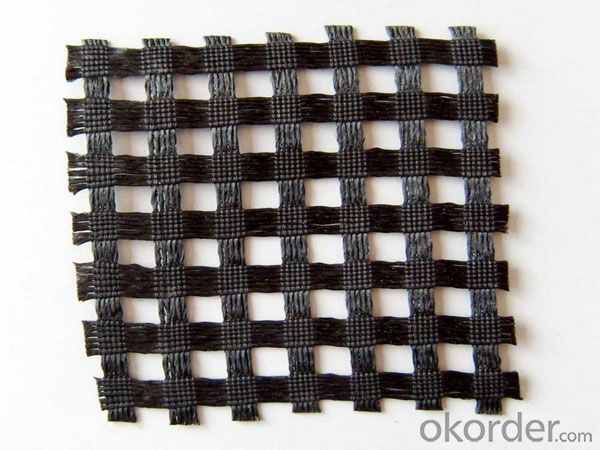

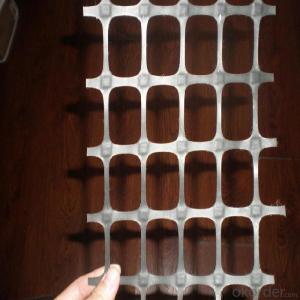

Structure of Corrosion Resistant Fiberglass Geogrid Description:

Corrosion Resistant Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Used for engineering reinforcement,10%,13% elongation,50x50mm holes size.

Main Features of Corrosion Resistant Fiberglass Geogrid:

Fiberglass Geogrid Improve roadbed bearing capacity,enlarge road lifetime.

Prevent road collapse and crack

Fiberglass Geogrid maninly applied in strengthen soft ground of rail and road

Could replace steel-plastic geogrid in coal mine.

Corrosion Resistant Fiberglass Geogrid Images

Corrosion Resistant Fiberglass Geogrid Specification:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the advantages of using geogrids in mechanically stabilized aggregate bases?

- There are several advantages of using geogrids in mechanically stabilized aggregate bases. Firstly, they improve the overall stability and strength of the base by distributing and transferring loads more efficiently. This helps to prevent deformations and rutting, leading to a longer-lasting and more durable pavement structure. Secondly, geogrids can reduce the thickness of the aggregate base required, resulting in cost savings and a more sustainable construction approach. Additionally, they enhance the performance of the base by minimizing the potential for differential settlement and improving overall load-bearing capacity. Finally, geogrids offer better long-term performance by resisting the effects of aging, such as cracking and degradation, which can significantly extend the lifespan of the pavement system.

- Q: Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to enhance stability, increase load-bearing capacity, and prevent soil erosion. They help to distribute the load more evenly, improve the overall structural integrity, and provide additional support to the landfill liner system.

- Q: Are geogrids compatible with different soil types?

- Yes, geogrids are generally compatible with different soil types. Geogrids are versatile materials that can be used with various soil types, including clay, sand, and gravel. They are designed to provide reinforcement and stability to the soil, improving its load-bearing capacity and preventing erosion. However, the specific type and design of the geogrid may vary depending on the soil characteristics and engineering requirements of the project.

- Q: How do geogrids improve soil stability?

- Geogrids improve soil stability by providing reinforcement and confinement to the soil, helping to distribute and transfer loads more evenly. They interlock with the soil particles, increasing the shear strength and preventing soil movement and erosion. Additionally, geogrids can enhance the load-bearing capacity of the soil, allowing for more efficient construction and reducing the risk of slope failures or settlement.

- Q: How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offer several advantages over other methods. They provide excellent tensile strength, allowing them to distribute loads and restrain soil movement effectively. Unlike traditional methods like soil nails or ground anchors, geogrids can be installed quickly and easily, reducing construction time and costs. Additionally, geogrids are resistant to chemical and biological degradation, making them a durable and long-lasting solution. Overall, geogrids offer superior performance, cost-effectiveness, and ease of installation compared to other soil reinforcement methods.

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids are a type of synthetic material that is placed on the surface of the soil to stabilize it and prevent erosion. They create a strong and stable barrier that helps to retain the soil in place, even under heavy rainfall or slope conditions. Additionally, geogrids can enhance the strength and load-bearing capacity of the soil, making them an effective solution for erosion control in various applications such as road construction, embankments, and retaining walls.

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of the geogrid material, the magnitude and duration of the applied load, the temperature and moisture conditions, the stiffness of the surrounding soil, and the installation and construction techniques.

- Q: How do geogrids help in reducing maintenance costs?

- Geogrids help in reducing maintenance costs by providing reinforcement to the soil, increasing its stability and load-bearing capacity. This prevents the need for frequent repairs and maintenance due to soil erosion, settlement, or structural failures. Geogrids also improve drainage, reducing the accumulation of water and preventing damage to the infrastructure, thereby minimizing maintenance expenses in the long run.

- Q: Can geogrids be used in retaining walls for highway projects?

- Yes, geogrids can be used in retaining walls for highway projects. Geogrids are commonly used in such projects to reinforce soil and provide stability to the retaining walls. They enhance the overall strength and durability of the walls, making them a reliable choice for highway construction.

- Q: Are geogrids suitable for reinforcing slope stabilization mats?

- Yes, geogrids are suitable for reinforcing slope stabilization mats. Geogrids provide additional strength and stability to the mats, helping to prevent soil erosion and maintain the integrity of the slope.

Send your message to us

Polypropylene Geogrids - Corrosion Resistant Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords