Dupont Geotextile 3D Honeycomb Polypropylene Filter Non-Woven Geotextile Fabric 100% PP Spunbond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

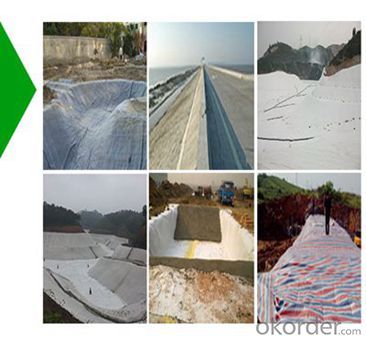

Application

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.Some commen uses of the material includes the following:

Road stabilization applications

Roofs

Civil applications

Railway work

Landfill lining

Trenches

Dams

Fitration under rip rap and rocks

Environmental applications

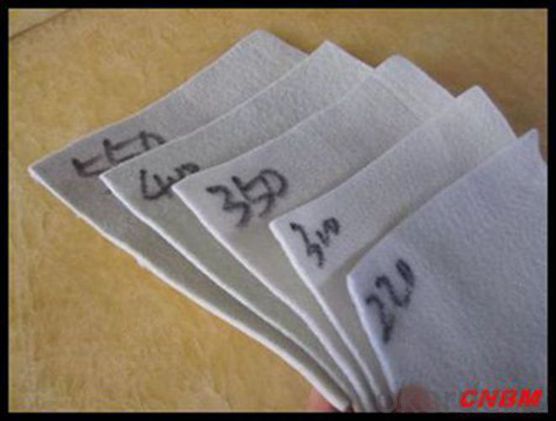

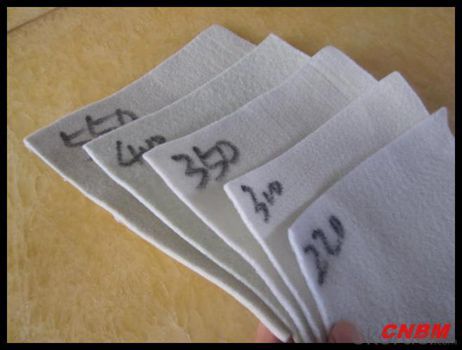

NO.Specifications and indicators100150200250300350400450500600800Remark

1Deviation of mass per unit area2)(%)-8-8-8-8-7-7-7-7-6-6-6

2Thickness (mm≥)0.91.31.72.12.42.733.33.64.15

3Amplitude-deviation(%)-0.5

4Breaking strength(KN/m≥)2.54.56.589.51112.514161925LD/MD

5Elongation at break(%)25-100

LD/MD

6CBR burst strength(KN≥)0.30.60.91.21.51.82.12.42.73.24

7Equivalent aperture090(095)(mm)0.07-0.2

8Vertical permeability coefficient(cm/s)K×(10-1-10-3)K=1.0-9.9

9Tearing strength(KN≥)0.080.120.160.20.240.280.330.380.420.460.6LD/MD

Note: TD=transverse direction LD=longitudinal direction

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to fire damage?

- Yes, geotextiles are generally resistant to fire damage. They are often made from materials such as polypropylene or polyester, which have inherent fire-resistant properties. Additionally, geotextiles can be treated with flame retardant additives to enhance their resistance to fire damage. However, it is important to note that the level of fire resistance may vary depending on the specific type and composition of the geotextile.

- Q: 300 grams per square meter of anti-geotextile there? what price

- Hello, 300 grams of geotextile with less, the best near the purchase of the specific price of the price can be a private letter or telephone I Hua Zhi geotextile material manufacturers for you to answer

- Q: Application Index of Geotextile Geotextile Expressway

- Application Index of Geotextile Geotextile Expressway

- Q: How do geotextiles contribute to soil drainage?

- Geotextiles contribute to soil drainage by allowing water to pass through them while preventing soil particles from being washed away, thus promoting efficient water flow and preventing soil erosion.

- Q: Geotextile what role

- The role of geotextile 1. Highway and railway construction for the separation of reinforced geotextile drainage; 2. Bank slope dam reinforcement geotextile; bridge engineering geotextile; waste piling pool; artificial pool with impermeable geotextile; cloth. 3. The effect of geotextile is: 1. The application of reinforcement can be stable, limit the displacement of civil engineering in the long-term use, and can make the local stress transfer or distribution in the soil To a larger area, to increase the friction between the soil and geotextile resistance. 2. Application of isolation with geotextile to separate the different soil structure, the formation of a stable interface, so that the structure of the separation of layers, in accordance with the requirements to play their respective characteristics and the overall role of 3. Protective effect of geotextile soil or Water, can play the role of protection and anti-fog, 4. the role of the application of geotextile soil can let the water through, but also effectively prevent the passage of soil particles, so as to prevent the loss of soil particles caused by soil damage, The application of non-woven geotextile in the soil can form a drainage channel, the soil together in the water, along the plane of the material out of the body. 5. Application of seepage prevention Geomembrane and composite geotextile material, can prevent the leakage of liquid, gas evaporation, environmental protection or building safety.

- Q: Can geotextiles be used in water retention projects?

- Yes, geotextiles can be used in water retention projects. Geotextiles are often used to reinforce soil and prevent erosion, making them suitable for applications such as retaining walls, embankments, and shoreline protection. In water retention projects, geotextiles can be used to create a barrier that traps water and prevents it from seeping into the surrounding soil, thereby increasing water retention.

- Q: Can geotextiles be used in temporary erosion control applications?

- Yes, geotextiles can be used in temporary erosion control applications. They are often used to stabilize soil and prevent erosion in construction sites, temporary roadways, and other areas where erosion control is needed temporarily. Geotextiles can effectively prevent soil erosion by providing a barrier that holds soil particles in place while allowing water to pass through.

- Q: Tunnel longitudinal drainage pipe with geotextile wrapped after the need for waterproof board wrapped, why can not be wrapped with a waterproof board

- You should say that the drainage pipe should be seepage of plastic blind tube it. Geotextile wrapped in the role is to play a filtering effect, filter the water to drain the sediment. Chong Hong geotextile material manufacturers

- Q: How are geotextiles installed?

- Geotextiles are typically installed by first preparing the ground surface, removing any vegetation or debris. Then, the geotextile fabric is unrolled and laid over the prepared area. It is important to ensure that the fabric is properly aligned and overlaps are secured. The geotextile is then anchored or weighted down to prevent any movement. Depending on the specific application, additional layers of geotextile or other materials may be added. Overall, proper installation techniques are crucial to ensure the effectiveness and longevity of geotextile applications.

- Q: Construction Technology of Seepage Control of Geotextile for Landscape Water System

- Laying HDPE geomembrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. Geomembrane thickness of not less than 0.25mm, too thin may produce pores, and easy to damage in the construction and reduce the anti-seepage effect. Geomembrane construction, in particular, should pay attention to laying should not be too tight, not wrinkled, stitching to be strong. Should be strictly in accordance with technical specifications construction, the good preparation, laying, splicing, inspection and backfill, such as five quality off. I specialize in production and construction

Send your message to us

Dupont Geotextile 3D Honeycomb Polypropylene Filter Non-Woven Geotextile Fabric 100% PP Spunbond

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords