Polypropylene Biaxial Geogrids for Noise Reduction - Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

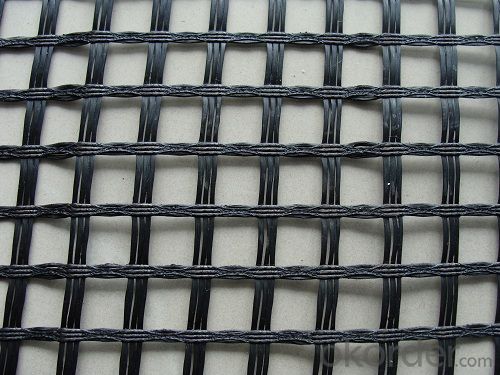

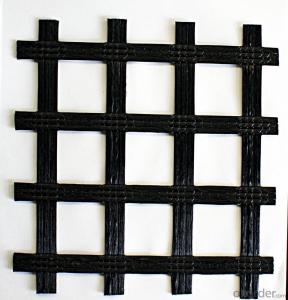

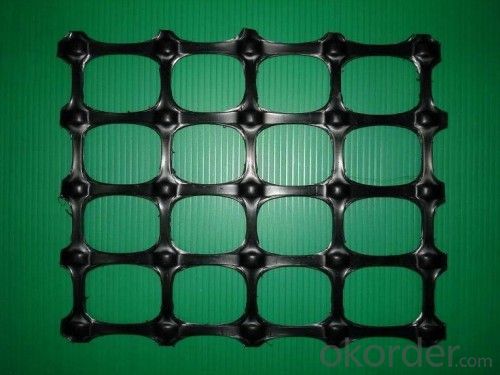

Double-direction geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce. Biaxial geogrid is made of pp/pe,mainly applied in highway, railway, slope protecting project

2. Product Characteristic:

1. High tensile strength, good creep resistance, chemical nature is stable;

2. Anti-corrosive, anti-aging, anti-UV, acidproof, alkaliproof, saltproof,etc.

3. The construction is convenient, the cycle is short and the cost is low.

3.Specification :

Type: Geogrids

Model Number: TGDG

Material: Plastic-Steel,HDPE/PP

Color: black etc.

Length: 50-100m (or at request)

Tensile strength: 15~100KN/M

Color: black and etc.

Material: PP/PE

CE/: ISO9001

4. Reference Picture:

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement and increased tensile strength to the soil. These grid-like structures are placed within the levee's soil layers, creating a stable and cohesive system. The geogrids distribute the applied loads more evenly and prevent soil erosion, enhancing the overall stability and strength of the levee structure.

- Q: What is the 110 type bidirectional geogrid?

- Geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching. It can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: How do geogrids help in pavement design?

- Geogrids help in pavement design by providing reinforcement and stabilization to the pavement layers, increasing their strength and durability. They distribute the load more evenly, reducing the potential for cracking and rutting. Geogrids also improve the overall performance of the pavement by enhancing its resistance to fatigue and reducing maintenance needs.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing stability to soil and reducing the need for excessive excavation and material usage. They allow for the use of locally available and low-quality soil, eliminating the need to import expensive and environmentally damaging materials. This reduces the amount of waste generated during construction and helps in preserving natural resources.

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can impact the installation and survivability of geogrids in harsh environments. Firstly, the quality and strength of the geogrid material itself play a significant role. Geogrids made from durable and high-quality materials are more likely to withstand harsh conditions. Secondly, the installation technique is crucial, as improper installation can lead to geogrids being damaged or dislodged. The type and condition of the subgrade also affect the geogrid's survivability, as a stable and well-prepared subgrade provides a solid foundation for the geogrids. Additionally, environmental factors such as extreme temperatures, moisture levels, and chemical exposure can impact the long-term performance and durability of geogrids in harsh environments.

- Q: How do geogrids affect soil compaction?

- Geogrids help to improve soil compaction by providing reinforcement and stability to the soil. They distribute the load more evenly, reducing the risk of settlement and improving overall soil strength. Additionally, geogrids enhance the interlocking behavior of soil particles, increasing the soil's resistance to shear forces and minimizing lateral movement.

- Q: What are the durability characteristics of geogrids?

- Geogrids are known for their high durability characteristics. They are typically designed to withstand heavy loads, harsh environmental conditions, and long-term exposure to various elements. Geogrids are made from strong materials such as polyester or polypropylene, which provide excellent tensile strength and resistance against stretching or deformation. Additionally, they have good chemical resistance, making them suitable for use in different soil types and corrosive environments. Overall, geogrids offer long-lasting performance and can provide reliable reinforcement and stabilization for various civil engineering applications.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in pipeline construction to reinforce the soil and prevent lateral movement or settlement. They provide additional support and stability to the ground, ensuring the pipeline remains in place and minimizes the risk of damage or failure.

- Q: Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are high-strength synthetic materials that can improve the stability and load-bearing capacity of soil structures. In the case of bridge abutments and wing walls, geogrids can be installed to provide additional reinforcement, reducing the potential for settlement and enhancing the overall performance and longevity of the structure.

- Q: Can geogrids be used for reinforcement in landfill liners?

- Yes, geogrids can be used for reinforcement in landfill liners. Geogrids are commonly used in landfill engineering to improve the stability and strength of liners by providing reinforcement and preventing soil erosion. They help to distribute loads evenly, enhance long-term performance, and increase the overall stability of landfill liners.

Send your message to us

Polypropylene Biaxial Geogrids for Noise Reduction - Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords