Solar Cells Hellas - Polycrystalline Solar Cells Tire 1 Manufacturer -16.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 50000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Solar Cells

A solar cell is a fabricated device that converts the sun’s light into electricity. If we want to get right into it, a solar cell takes the energy from the sun’s light rays, by using the colliding light at the photon level to split apart the electron-hole pairs. When the photon hits the pair, they break, and one part goes north one part south. The stronger the sun, the quicker and more this happens. This process is called the photoelectric effect. The following diagram explains.

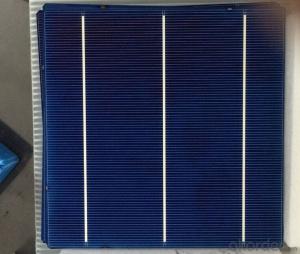

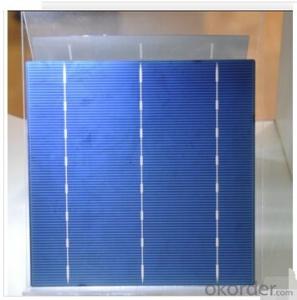

Specifications of Polycrystalline Solar Cells

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

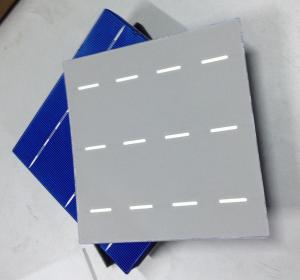

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Efficiency (%) | Pmpp (W) | Umpp (V) | Impp (A) | Voc (V) | Isc (A) |

18.00% | 4.38 | 0.528 | 8.291 | 0.631 | 8.869 |

17.80% | 4.33 | 0.525 | 8.252 | 0.629 | 8.821 |

17.60% | 4.29 | 0.532 | 8.053 | 0.633 | 8.541 |

17.40% | 4.23 | 0.528 | 8.092 | 0.624 | 8.632 |

17.20% | 4.19 | 0.524 | 7.992 | 0.62 | 8.458 |

17.00% | 4.14 | 0.52 | 7.972 | 0.623 | 8.5 |

Advantage of Polycrystalline Solar Cells

High conversion efficiencies resulting in superior power output performance.

Suitable for keeping appearance of solar cell tidy and clean.

Advanced diffusion technology adapted to ensure conversion efficiency uniformity throughout cell.

Advanced PECVD film forming technology used to coat cells with dark blue silicon nitride anti-reflection coatings.

Uniform color appearance.

Advanced soft line and high precision silkscreen printing equipment to achieve high smoothness, make automatic welding and laser cutting easier.

Metal paste applied to making back surface field and electrode to ensure top conductivity, nice adhesion, superior weld-ability, nice appearance and reliable performance.

Efficiency, stability and durability of crystal silicon.

Low breakage rate.

Environmental protection.

OEM orders are welcome

Usage of Polycrystalline Solar Cells

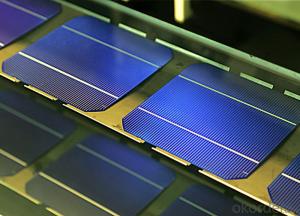

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Applications of Polycrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Factory Picture of Solar Cells

We have organized several common questions for our clients,may help you sincerely:

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Have you ever been to a solar cell power generation station?

- I know a company named SUNPOWER is famous for that.

- Q: What is the maintenance required for solar cells?

- The maintenance required for solar cells primarily involves regular cleaning to remove any dirt, debris, or grime that may accumulate on the surface of the panels. Additionally, it is important to inspect the panels for any damage, such as cracks or loose connections, and address them promptly to ensure optimal performance. Other routine maintenance tasks include checking the inverters, monitoring the system's performance, and keeping the surrounding area free from shading objects. Overall, solar cell maintenance is relatively minimal compared to other energy sources, making it a cost-effective and sustainable choice for power generation.

- Q: What is the payback period for solar cells?

- The payback period for solar cells depends on various factors such as the initial cost of installation, the amount of electricity generated, and the cost of traditional energy sources in the area. On average, solar cells have a payback period ranging from 5 to 10 years, but in some cases, it can be as short as 3 years or as long as 20 years.

- Q: What is the pollution of solar cells?

- the city warehouse classification storage; 5, centralized custody, waiting for the introduction of domestic waste battery recycling technology; 6, increase the size of the battery recycling; 2, regular hand-site acquisition; 3, battery classification (ordinary battery, button batteries)

- Q: How can solar cells be used in residential applications?

- Solar cells can be used in residential applications by installing solar panels on rooftops or other open areas to capture sunlight and convert it into electricity. This clean and renewable energy source can power various appliances and lighting systems within a home, reducing reliance on traditional grid electricity and lowering utility bills. Additionally, excess energy generated by solar cells can be stored in batteries or fed back into the grid, further promoting sustainability and potentially earning homeowners credits or incentives.

- Q: Can solar cells be used in disaster response vehicles?

- Yes, solar cells can be used in disaster response vehicles. They can help power the vehicle's electrical systems and equipment, providing a sustainable and reliable source of energy in emergency situations where traditional power sources may be unavailable or unreliable. Additionally, solar cells can reduce the dependence on fossil fuels and contribute to a more environmentally friendly response effort.

- Q: How are solar cells integrated into building designs?

- Solar cells can be integrated into building designs through various methods such as rooftop installations, solar facades, and building-integrated photovoltaics (BIPV). These methods involve incorporating solar panels into the structure of the building, either on the roof or as part of the facade, allowing for the generation of clean and renewable electricity while seamlessly blending with the overall architectural design.

- Q: Can solar cells be used in harsh climates?

- Yes, solar cells can be used in harsh climates. While extreme temperatures, snow, and dust can potentially affect the efficiency and performance of solar cells, advancements in technology and design have made them more resilient. Specialized coatings, materials, and mounting systems are employed to protect solar cells from harsh weather conditions. In fact, solar panels are increasingly being used in various extreme climates around the world, including deserts and polar regions, proving their adaptability and effectiveness even in challenging environments.

- Q: What are the short-circuit currents of solar cells affected by the factors?

- Silicon cell: the life of the minority after the diffusion, silicon impurity content, silicon chip resistivity, cashmere suede, PE anti-reflective film anti-reflective effect, the front gate line printing and so on affect the short-circuit current.

- Q: Can solar cells be used for powering traffic lights?

- Yes, solar cells can be used for powering traffic lights. Solar panels can harness sunlight and convert it into electricity, providing a sustainable and renewable source of power for traffic lights. This eliminates the need for traditional electrical grid connections and reduces carbon emissions. Solar-powered traffic lights are increasingly being adopted as an eco-friendly and cost-effective solution in many locations around the world.

Send your message to us

Solar Cells Hellas - Polycrystalline Solar Cells Tire 1 Manufacturer -16.6%

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 50000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords