Second Generation Thin Film Solar Cell with TUV/ UL/ CE/ ROHS/ IEC/ CQC/ ISO/ SFEC/ CEC Approval

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Thin film solar system energy yield per Wp can be 10% higher than that of silicon solar system due to material characterics.

Amorphous silicon thin film solar panel, with TUV/ UL/ CE/ RoHS/ IEC/ CQC/ ISO/ SFEC/ CEC approval.Framed by black anodized aluminium, easy to fix or made into free standing type. AmpleSun ASF series have many advantages with high quality production process and raw materials:

General advantages:

1. Good environment adaptability, less sensitive to installation angle, more suitable for vertical installation in BIPV.

2. Excellent performance.

3. 30% lighter than double-glass type.

4. Framed with aluminium makes ASF more solid.

5. Good looking, well match the buildings or as a constituent part.

6. Free from defects for 5 year with regular use, maintain more than 90% of Max. power for 10 years and 80% for 25 years.

Technical advantages:

1. Low temperature coefficient:

Normally, the electricity performance of photovoltaic module is measured by STC standard. However, the temperature of solar module, operating in the sun, can be much higher than atmosphere temperature.

With the temperature increase, module power will decrease accordingly. Temperature coefficient for thin film silicon solar cell is 0.2%/0c, and that of crystalline solar cell is -0.5%/0c. That means, when the module is worked on 500c condition, compare to the efficiency reached on 250c test standard , thin film silicon solar module will loose around 5%, and the loss for crystalline will be around 12.5%.

In conclusion, even the STC efficiency of thin film silicon solar cell is low, the efficiency in actual operation condition is not far away to that of crystalline solar cell.

2. Good weak light performance:

The performance of thin film silicon solar cell is better than that of crystalline solar cell in the weak light condition.

Solar power system with crystalline solar module will not generate power in the late afternoon. However, solar power system with thin film silicon solar cell still generates power.

Furthermore, thin film silicon has gentle current-voltage curve. This characteristic makes it easier to pick-up the most electricity power.

Brief introduction of Thin Film Solar Cell

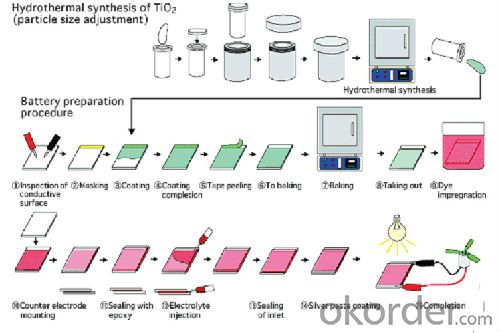

Thin film solar cells can be made up with inexpensive ceramics, graphite, metal sheets of different materials as substrates. The film thickness can be formed to generate a voltage of just a few μm; the highest conversion efficiency of the thin film solar cell can be up to 13% currently.

Physical Advantage of Thin Film Solar Cell

Now the main material of thin film solar cell is silicon. In the share of the cost of the finished solar cells, silicon materials accounted for nearly 40%. The thickness of amorphous silicon solar cells is less than 1μm, which is less than 1/100 of the thickness of crystalline silicon solar cells, reducing the manufacturing cost greatly. Since the amorphous silicon solar cell manufacturing low temperature (-200 ℃), is easy to realize the advantages of a large area, so that it takes primacy in the thin film solar cell, the manufacturing methods in electron cyclotron resonance method, photochemical vapor deposition method, DC glow discharge, radio frequency glow discharge method, sputtering method and Xie hot-wire method. Especially the RF glow discharge method because of its low temperature process (-200 ℃), easy to implement large-scale and high-volume continuous production, is now internationally recognized as a mature technology. Especially the RF glow discharge method because of its low temperature process (-200 ℃), easy to implement large-scale and high-volume continuous production, is now internationally recognized as a mature technology. In materials research, has studied a-SiC window layer, graded interface layer, μC-SiC p layer, etc., and significantly improves the short-wave spectral response of the cell. This is due to the a-Si solar photo-generated carriers generated mainly in an i-layer, i-layer before reaching the incident light is absorbed by the p-layer portion of the power is invalid. The a-SiC and μC-SiC material than the p-type a-Si has a wider optical band gap, thus reducing the absorption of light that reaches the light increases the i-layer; gradient interface layer coupled with improved a- transport properties of SiC / a-Si heterojunction interface photoelectrons in response to increase in the long-wave, using a suede TCO film, a multi-layer suede back reflection electrode (ZnO / Ag / Al) and multi-bandgap stacked structure, That glass / TCO / p1i1n1 / p2i2n2 / p3i3n3 / ZnO / Ag / Al structure. Suede TCO film and the electrode multilayer back reflector reduces light reflection and transmission losses and an increase in the propagation of light from the i layer, thereby increasing the light absorption in the i-layer multi-band-gap structure, with the i-layer gap width begin to gradually decrease from the light incident direction to absorb sunlight segment reached broaden the spectral response, the purpose of improving the conversion efficiency. Improving the efficiency of the battery stack also features graded bandgap design, tunnel junctions of microcrystalline doped layer, so as to improve the carrier collection.

- Q: How long does it take for solar cells to pay for themselves?

- The payback period for solar cells typically ranges from 5 to 10 years, depending on various factors such as the initial cost, energy consumption, and local solar incentives.

- Q: Can solar cells be damaged by hail or other weather events?

- Yes, solar cells can be damaged by hail or other severe weather events. Hailstones, strong winds, and heavy debris can crack or break the delicate glass surface of solar panels, reducing their efficiency or rendering them completely non-functional. Therefore, it is important to consider the durability and quality of solar panels when installing them in areas prone to such weather conditions.

- Q: Can solar cells be used to power remote monitoring systems?

- Yes, solar cells can be used to power remote monitoring systems. Solar cells convert sunlight into electricity, providing a reliable and sustainable source of power for monitoring devices located in remote or off-grid areas where traditional power sources are not available or feasible. This makes solar cells an ideal solution for powering remote monitoring systems.

- Q: Can the 156x156mm high efficiency single crystal cells assembly function better compared to the traditional one?

- Our company is planning to upgrade our supply system into the 156x156mm high efficiency single crystal celsl assembly, but we are still not sure if it is really that great.

- Q: Can anybody tell me the power supply of the home solar cell?

- In my old place, all I was using was the 50WAT solar cells, which is definitely good and useful for all my daily use.

- Q: Can solar cells be used in underwater vehicles?

- Yes, solar cells can be used in underwater vehicles. However, due to the limited availability of sunlight underwater, the efficiency of solar cells is significantly reduced compared to their performance on the surface. Therefore, other power sources such as batteries or fuel cells are often used in conjunction with solar cells to provide continuous power to underwater vehicles.

- Q: Can solar cells be used in water heating systems?

- Yes, solar cells can be used in water heating systems. They can be used to capture sunlight and convert it into electricity, which can then be used to heat water through various mechanisms such as heating elements or heat exchangers. This allows for a more sustainable and cost-effective way of heating water, reducing reliance on traditional energy sources.

- Q: Why are the poly Solar cell specifications is different from each other, they seem to have the different size of 125mm, 156mm, 152mm, is the 152mm's battery technology is higher than the other?

- The poly solar cell which is 156mm is not necessary high technology-based than the others. In fact, it's less efficient than the others.

- Q: What is the effect of wind on solar cell performance?

- The effect of wind on solar cell performance can be both positive and negative. On one hand, wind can help cool the solar cells, preventing overheating and improving their overall efficiency. Additionally, wind can help clean the surface of the solar panels, removing dust and debris that may obstruct sunlight and reduce energy production. On the other hand, strong winds can create vibrations and mechanical stress on the solar panels, potentially damaging their structure or causing misalignment. Therefore, while some wind is beneficial for solar cell performance, excessive or turbulent wind conditions may have a detrimental impact.

- Q: What is the impact of solar cell installations on property values?

- Solar cell installations have been found to have a positive impact on property values. Studies have shown that homes with solar panels tend to sell for a higher price and at a faster rate compared to those without. The perceived energy savings and environmental benefits associated with solar energy make properties with solar installations more attractive to potential buyers, resulting in increased property values.

Send your message to us

Second Generation Thin Film Solar Cell with TUV/ UL/ CE/ ROHS/ IEC/ CQC/ ISO/ SFEC/ CEC Approval

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords