PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Elastomer (SBS) Modified Bituminous Waterproof Sheet Material is a thermoplastic and elastic

modified bituminous dipping and coatingmaterial made out of Stylene-Butadiene-Stylene (SBS),the filler base is polyester felt, glass fiber felt and glass fiber reinforced polyester felt, it is a kind of rollable sheet water proof materials with the surface cover of the isolating materials like polyethylene film, fine sand and mineral slice (or particle) etc.

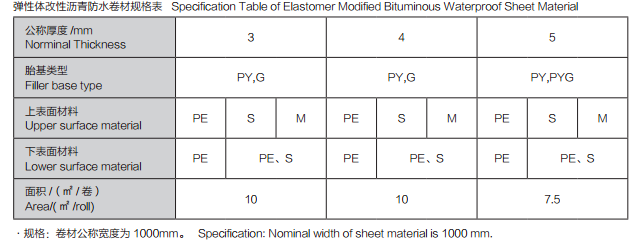

Type and Specification

Classified by filler base: Polyester filler (PY), glass fiber

filler(G) and glass fiber reinforced polyester filler (PYG).

·Classified by upper surface isolating material: Polyethylene

film (PE), fine sand (S) and mineral particle (M).

·Classified by lower surface isolating material: Fine sand

(S) (note: the mineral particle with the fine sand diameter not

more than 0.6mm) and polyethylene film (PE).

·The physical and mechanical properties were divided in

Type Ⅰ and Type Ⅱ.

Advantages

—Filament polyester filler base sheet material:

·The combination of filament polyester filler base and SBS

modified bitumen, forms a high performance and high class

comprehensive water proof sheet material.

·Forming a high strength water proof layer, to have strong

resistance agaist water pressure.

·Good performance of breaking resistance, tearing resistance,

fatigue resistance, corrosion resistance, mould resistance and

weather resistance;

·High tensile strength, high elongation, high adaptive capacity to

base shrinkage,deformation and fracture.

·Good resistance performance of low and high temperature: It

still works under -50 ℃ , adaptive to cold and hot surroundings,

especially in chilly region.

·Good workability: Hot melt cementation, we are able to contruct

in the four seasons of the whole year, hot-joint is able to be reliable

and durable.

—Alkali-free glass fiber filler base sheet material:

·Combination of economical filler base and high performance

SBS modified bitumen.

·Higher tensile strength, excellent resistance to high and low

temperature.

·Good performance of corrosion resistance, mould resistance,

weather resistance and good workability.

—Glass fiber reinforced polyester filler base sheet material:

·We may use mechanical mounting method to construct, and it is

safe and environmentally friendly.

·The product has better dimensional stabiliy.

·Water proof for various industrial and civil engineerings.

·Underground water proof and damp proof for industrial and civil

engineering, and water proof for indoor swimming pool and fire pool

etc.

Application Range

·Water proof for municipal engineering such as subway, tunnel,

concrete road surface, bridge surface, sewage works and refuse

landfill etc.

·Water proof for water conservancy facilities like canal and water

pool etc .

Application range for various filler base and surface sheet

material:

·Polyester felt filler base elastic modified bituminous water proof

sheet material is appropriate to the roof and underground water

proof engineerings of industrial and civil engineering projects.

·Water proof type Ⅱ is appropriate to roof type Ⅰ and Ⅱ and

underground water proof projects.

·Glass fiber reinforced polyester filler base sheet material is

appropriate to mechanically-mounted single layer water proof, but

must pass the wind load test.

·Glass fiber felt filler base sheet material is appropriate to the roof

of structurally stable building and suitable for underground water

proof project.

·Exposed surface is suitable to have water proof sheet material

with non-transparent mineral particle as upper surface isolating

material.

·The water proof sheet material with find sand as surface

isolationg material is appropriate to underground constructioin

project.

- Q: Can a waterproofing membrane be used for concrete tank linings?

- Yes, a waterproofing membrane can be used for concrete tank linings. A waterproofing membrane is designed to create a barrier against water penetration, which makes it suitable for protecting concrete tanks from potential leaks or moisture damage.

- Q: Are waterproofing membranes suitable for tunnels?

- Tunnels can benefit from the use of waterproofing membranes. These structures often face significant water pressure from the surrounding soil and groundwater, making them susceptible to water entering. Waterproofing membranes are specifically designed to create a protective barrier that prevents water infiltration into the tunnel. These membranes are typically crafted from durable materials like bitumen, PVC, or EPDM rubber. These materials possess a resistance to water penetration, making them ideal for the task. Once applied to the tunnel walls and ceiling, they form a continuous and impermeable layer that effectively keeps the tunnel dry. Additionally, the membranes are flexible, allowing them to adjust to any movement or settlement within the tunnel while maintaining their waterproofing integrity. Apart from their water-blocking capabilities, these membranes offer other advantages for tunnels. They can shield the structure from corrosion caused by water and chemicals, thereby prolonging the tunnel's lifespan. Furthermore, they can improve the indoor air quality by preventing the growth of mold and mildew, which tend to thrive in damp environments. Moreover, waterproofing membranes can be tailored to suit the specific conditions of different tunnels. For instance, in tunnels exposed to high levels of hydrostatic pressure, reinforced membranes with greater tensile strength can be used to withstand the additional stress. Similarly, tunnels that prioritize fire safety can utilize membranes with enhanced fire resistance properties. In conclusion, waterproofing membranes provide a dependable and efficient solution for ensuring the durability, safety, and longevity of tunnels. By serving as a robust barrier against water ingress, they effectively safeguard these structures.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits. Elevator pits and sump pits are prone to water infiltration, and a waterproofing membrane can effectively prevent water from seeping into these areas. The membrane acts as a barrier, preventing any water from entering the pit and causing damage to the elevator or pumping system. This helps to maintain the integrity of the elevator or pump and prolong its lifespan. Additionally, a waterproofing membrane can also protect the surrounding structures and prevent any water damage. It is important to select a suitable waterproofing membrane that is designed for below-ground applications and has the necessary properties to withstand the specific conditions in an elevator or sump pit.

- Q: Can waterproofing membranes be used on stormwater management systems?

- Yes, waterproofing membranes can be used on stormwater management systems. These membranes provide a protective barrier that prevents water from infiltrating into the system, ensuring efficient and reliable stormwater management.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Precast stone block surfaces can benefit from the application of a waterproofing membrane. These membranes are frequently utilized to safeguard a variety of surfaces, including precast stone blocks, from water infiltration and moisture harm. The purpose of these membranes is to establish a barrier that prevents water from seeping into the surface and causing problems like mold, decay, or structural deterioration. By applying a waterproofing membrane to precast stone block surfaces, their durability and lifespan can be improved by shielding them from water-related difficulties. However, it is crucial to diligently adhere to the manufacturer's instructions and ensure that the chosen waterproofing membrane is appropriate for the specific type of precast stone block surface being treated.

- Q: Can a waterproofing membrane be used for roofing applications?

- Indeed, a waterproofing membrane can be utilized in roofing applications. Specifically designed to create a barrier against water infiltration, waterproofing membranes are commonly employed in a range of construction projects, including roofs. These membranes typically consist of durable materials like synthetic rubber, thermoplastics, or modified bitumen, renowned for their water-resistant properties and longevity. By installing a waterproofing membrane on the roof, one can effectively safeguard the building from water leaks and moisture penetration, which may result in structural damage, mold growth, and other related problems. The membrane is typically applied seamlessly onto the roof surface, forming a watertight layer that prevents water from permeating through. Waterproofing membranes for roofing applications are available in various types, such as sheet membranes, liquid or spray-applied membranes, or self-adhering membranes. Each type offers distinct advantages and suitability depending on the specific roofing requirements and construction conditions. In conclusion, a waterproofing membrane is indeed a viable choice for roofing applications, providing an efficient solution to ensure a durable and watertight roof system.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Certainly, it is possible to utilize a waterproofing membrane in regions with elevated groundwater levels. In truth, it is strongly advised to employ a waterproofing membrane in such areas to safeguard the integrity of the edifice from water penetration. The primary purpose of a waterproofing membrane is to construct a barrier that hinders the ingress of water into the building or structure. This becomes particularly crucial in zones with high groundwater levels due to the substantial pressure exerted by the water, which heightens the chances of water damage or flooding. By implementing a waterproofing membrane, you can effectively minimize the risk of water infiltration and ensure the long-lasting resilience of the structure.

- Q: Can a waterproofing membrane be used for a hotel swimming pool area?

- Yes, a waterproofing membrane can be used for a hotel swimming pool area. A waterproofing membrane is a specially designed material that is applied to surfaces to prevent water penetration. It forms a protective barrier that prevents water from seeping into the underlying structure, protecting it from damage caused by water exposure. In the case of a hotel swimming pool area, a waterproofing membrane can be applied to the pool shell and surrounding areas to prevent water from leaking into the building or surrounding structures. This helps to maintain the integrity of the pool area and prevent any potential water damage. Additionally, a waterproofing membrane can also help to prevent the growth of mold and mildew, as it creates a moisture barrier. Therefore, using a waterproofing membrane for a hotel swimming pool area is a wise choice to ensure the longevity and durability of the pool and surrounding structures.

- Q: Can a waterproofing membrane be used in conjunction with other waterproofing methods?

- Yes, a waterproofing membrane can be used in conjunction with other waterproofing methods. In fact, combining multiple waterproofing methods can provide enhanced protection against water damage and ensure a more reliable and long-lasting waterproofing solution. The membrane can act as an additional layer of defense, complementing other methods such as sealing, drainage systems, or coatings, to provide a comprehensive waterproofing system.

- Q: Can a waterproofing membrane be used for a garden pond liner?

- Yes, a waterproofing membrane can be used for a garden pond liner. A waterproofing membrane is designed to prevent water from penetrating through it, making it an ideal choice for creating a watertight barrier in a garden pond. It can effectively prevent leaks and ensure that the water remains contained within the pond. Additionally, waterproofing membranes are typically durable and resistant to UV rays, chemicals, and punctures, which are all important factors to consider when selecting a material for a pond liner. However, it is crucial to ensure that the waterproofing membrane chosen is specifically designed for use in ponds and is safe for aquatic life.

Send your message to us

PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords