Hammer Crusher Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set

- Supply Capability:

- 5 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production capacity (m3/h): 30-45

Discharge particle size (mm): 0-8

Equipped Power (KW): Y4-75

Equipped V belt (mm): 6D-4500

Dimension (L×W×H)mm: 1400×1750×1880

(2)Type: PC100×80

Production capacity (m3/h): 15-20

Discharge particle size (mm): 0-5

Equipped Power (KW): Y4-75

Equipped V belt (mm): 5D-5000

Dimension (L×W×H)mm: 1250×1680×1600

(3)Type: PC80×55

Production capacity (m3/h): 10-15

Discharge particle size (mm): 0-5

Equipped Power (KW): Y4-55

Equipped V belt (mm): 5D-3600

Dimension (L×W×H)mm: 1080×1400×1400

Specifications of Hammer Crusher:

1.Large reduction ratio

2.Uniform particle size

3.Little over-crushing

4.High wear resistance of hammerhead

5.Large size of feed

6.Simple structure, reliable work

7.Compact structure, easy maintenance

8.Low energy consumption, operating costs

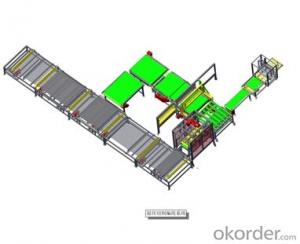

- Q: Brief introduction of the brick machine

- The hoist is located at the top of the pallet box and the raw material hydraulic conveyor, and is mounted on the column of the mainframe frame. The mold head and the fuel tank are connected by four tubing, and the mold sleeve is installed on the main frame elastic support device.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine is the production of brick-free brick brick machine, is the production of brick can not be used.

- Q: What are the brick-making materials?

- This is to see what kind of brick machine, such as Mianshaozhuanji raw materials can be fly ash. Stone powder. Sand. Slag. Slag. Water slag. Ceramics. Construction waste, etc. to be a detailed understanding

- Q: Automatic concrete brick machine bearing how to choose?

- After repair or adjustment of the discharge port, you should first use manpower to change the rotor, recognize the rotor and other parts do not conflict and stuck appearance and can be sensitive to change

- Q: Installation and commissioning of hydraulic press

- 3, check the working parts of the cylinder and the lubrication point is required to refuel, oil is appropriate.

- Q: The scope of application of building waste brick machine

- The initial strength of the industrial waste slag-free brick is obtained during the brick forming process. Molding not only has a certain strength of the brick, and because of the close contact between the raw material particles to ensure that the physical and chemical effects between the particles can be carried out efficiently for the formation of late strength to provide the conditions.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Third: carefully adjust the gap, including the indenter and the core, indenter and material car movement plane, mold frame and line plate spacing, the relative movement can not interfere,

- Q: What is the principle of vacuum brick machine

- Vacuum brick machine for coal gangue, shale, fly ash and clay and other raw materials to produce all kinds of hollow brick. The machine is equipped with wear-resistant metal powder spray coating technology; superior mixing shaft, mud knife shaft and body up and down body, etc., are aging, quenching and tempering, quenching; reducer gear are hard tooth; Pressure patented technology, a substantial increase in equipment life.

- Q: How does the economical brick machine use the building waste brick?

- and then through the construction waste brick machine further processing into a building products. Therefore, the reuse of construction waste needs to be divided into two parts,

- Q: Cement brick machine related issues

- There are many types of cement brick machine, mainly to see what kind of brick you need to produce, and now the main use of a kind of eight-hole turntable, this machine equipment using a wide range of raw materials, the machine's main features are: Convenient, with pressure display, mechanical failure alarm, power supply distance protection, automatic control of oil supply, easy installation and other functions.

1. Manufacturer Overview

| Location | Fujian,China (Mainland) |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | 30.00% Africa 20.00% Mid East 15.00% Southeast Asia 10.00% Eastern Asia 5.00% North America 5.00% South Asia 5.00% South America 5.00% Eastern Europe 5.00% Oceania |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | shanghai,shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese, Portuguese, Arabic |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Hammer Crusher Hot Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 set

- Supply Capability:

- 5 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords