The world's best-selling belt feeder for mining and ore industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

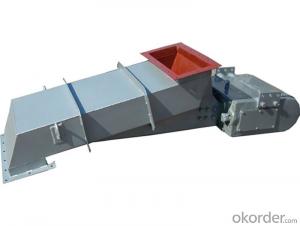

The world's best-selling belt feeder

Overview:

The world's best-selling belt feeder is environmentally friendly, energy efficient new product, which is characterized by the traditional K-type reciprocating feeder to the gap between the reciprocating feed to continuous conveying feed.

Transmission power is combined stepless speed reducer motor, the belt speed can be adjusted manually or via the drive.

Application:

The world's best-selling belt feeder can be widely used in bulk material conveying system of coal, metallurgy, construction, chemical industry and other industries.

Advantages:

1.Stable operation, high speed, low noise, explosion-proof performance is good, is an environmentally friendly products.

2.High feeding capacity, up to thousands of tons per hour.

3.According to the needs of users, the amount of material can be arbitrarily adjusted by auto or manual.

4.Simple installation, low cost of technical transformation.

5.With arch breaking device, ensure the material smoothly.

6.Reliable quality, stable performance.

7.Completeauxiliary facilities,complete function.

8.Feeding roller is arranged at the bottom of the silo body,enhanced impact ability, and the service life is long.

Technical Parameters:

Model | Power | Speed mode | Speed range (m/s) | Feeding range (t/h) | Weight (kg) |

GLD800/5.5/S | 5 | Manual | 4~0.7 | 160~800 | 3700 |

GLD800/5.5/B | Automatic | 42~0.7 | 480~800 | 3800 | |

GLD2000/5.5/S | 5/7.5 | Manual | 6~0.1 | 400~2000 | 4200 |

GLD2000/5.5/B | Automatic | 2~0.1 | 1200~2000 | 4300 | |

GLD3300/7.5/S | 5 | Manual | 2~0.1 | 660~3300 | 5200 |

GLD3300/7.5/B | Automatic | 6~0.1 | 1980~3300 | 5300 | |

GLD4400/11/S | 11 | Manual | 3~1.5 | 880~4400 | 6200 |

GLD4400/11/B | Automatic | 9~1.5 | 2640~4400 | 6300 |

- Q: The opening process of press filter from feeding to discharging is described briefly

- Close all piping valves and continue to remove extrusion pressure.After opening the filter, the filter press is opened and the cake discharge is carried out.

- Q: What's the simplest ore radio to do?

- 2AP9 diode is a 600 ohm above the earplug foil 65 cm long 2 cm wide kraft paper a 70 cm long 3 cm wide and 3 meters to a copper wire wrapped in kraft paper in electric wire and copper wire tin foil wrapped in kraft paper outside the 3 meter long wire peeling exposed around 1 meters above the other foil one end is connected with the grounding wire and radio headset diode parallel diode cathode copper wire electrode tap water pipe is connected with a tap water pipe line lamp is very simple and don't pay attention to the leakage

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- Tangential feed -- from tangential direction is fed into the crushing chamber, the common good, not only crushed grain, also crushed small cake and chopped stalk and forage.

- Q: How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size and production capacity of crushing equipment, whether it is what it needs

Send your message to us

The world's best-selling belt feeder for mining and ore industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords