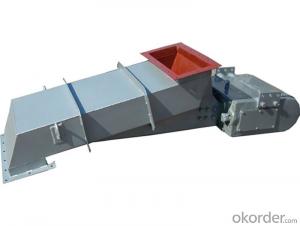

ZG vibrating feeder|High - quality feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vibrating feeder is the first equipment in the process of aggregate production line. The high-quality feeder helps the overall production efficiency of the aggregate production line.

The vibration feeder comprises a tank body, a vibration plate, a motor base and a vibration motor. In the traditional equipment, the bottom plate and the side plate of the tank are mostly using welding technology. This method is easy to produce welding deformation due to the welding stress. The improved feeder adopts bolt connection structure to solve the problem effectively. The motor base is the motor bearing The force of the place, especially through the steel plate cutting welding, after milling, and then drill hole drilling to ensure that the welding quality and size of precision; damping spring hydraulic universal testing machine to determine the value of static stiffness, the similar election With the number and then the whole assembly; vibration motor ring groove seal is used to ensure that the bearing lubrication effect, the vibration motor to play all the performance while a long service life.

These are only part of the equipment manufacturing, good equipment, only through advanced technology, good production equipment, and then by the superb work of the producers to produce its unique advantages.

- Q: The opening process of press filter from feeding to discharging is described briefly

- Start and close the filter press.Open the feed valve.Starting feed pump.Control feed pressure or time, or two at the same time, to the set value, stop feeding.Close feed valve.With diaphragm extrusion equipment, start the diaphragm extrusion pump, correctly open the valve of each extrusion system, control the extrusion pressure, and then stop the extrusion after the setting value.Slow release of extrusion pressure, generally to about 7bar, stop pressure release.

- Q: What's the simplest ore radio to do?

- The most simple ore radio, a three meters above the overhead antenna, a ground wire, a 2AP9 diode, a high impedance diode in parallel with the headset, headset received two world online, only listen to the strongest local Taiwan, if there is more than a strong one mix together.

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- The feed enters the crushing chamber from the top of the rotor, the rotor can be reversed and used, and the hammer can be replaced less than two times. The feed is mainly suitable for processing fine fodder.

- Q: How to choose crushing equipment suitable for its own ore material?

- To see the hardness and brittleness of the ore material itself, if these can not clear the direct contact of crushing equipment manufacturers, they are generally more clear, can choose the required type of crushing equipment according to the characteristics of the material itself, such as hard material cracking, general hardness can be used to hammer breaking etc.

Send your message to us

ZG vibrating feeder|High - quality feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords