Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

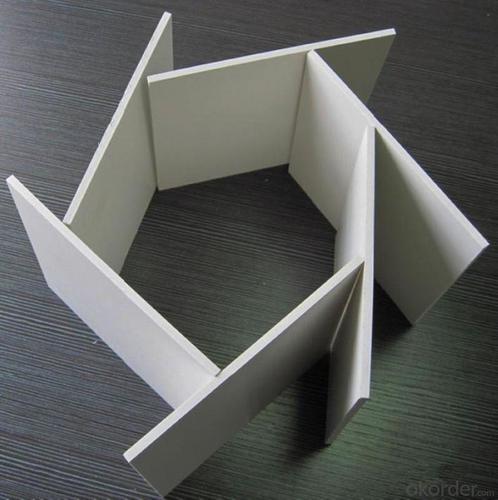

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

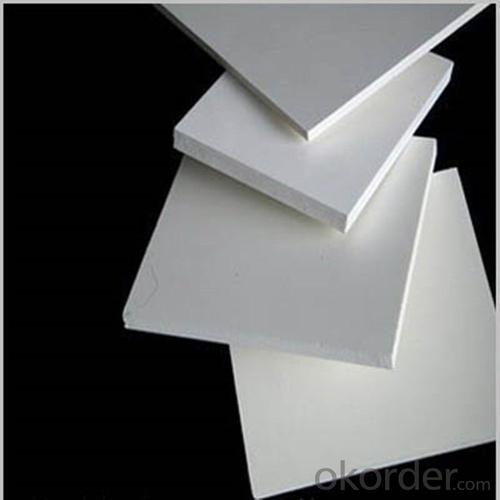

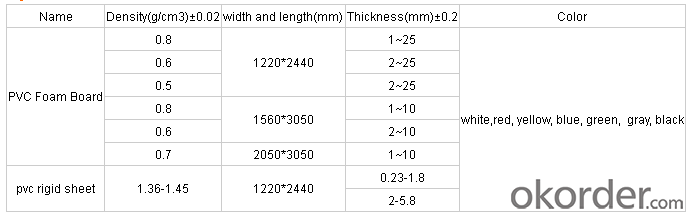

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

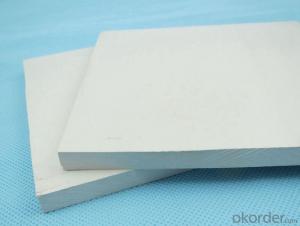

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

FAQ

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

4. Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

Answer :we are manufacturer specializing in stationery and plastic packing products in highly quality and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,packages of cosmetic and other daily necessities, they are mainly famous ,such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

More Details of Product

- Q: At the end of my dentist appointment, my dentist asked to bite down hard on this black sheet of rubber or plastic and then he would pull it out.

- Sounds like he was using articulating paper. You bite on it and it leaves a colour (usually red or blue) on the teeth were they touch the opposing teeth. If your dentist has just done a filling for example they will check that they have not altered your bite by propping your mouth open or allowing no contact to be made, as both of these situations will cause problems. However if if was a rubbery mixture in a tray which was inserted over all your teeth and you were asked to bite into it, he was taking impressions. If your still unsure just ask, im bet he will be pleased to tell you hope this helps :-)

- Q: Are plastic sheets resistant to discoloration from outdoor exposure?

- Yes, plastic sheets are generally resistant to discoloration from outdoor exposure.

- Q: Are plastic sheets resistant to warping or bending with heavy loads?

- Yes, plastic sheets are generally resistant to warping or bending with heavy loads. However, the extent of their resistance may vary depending on the specific type and thickness of the plastic sheet being used.

- Q: Can plastic sheets be cut to custom sizes?

- Yes, plastic sheets can be cut to custom sizes.

- Q: How do plastic sheets compare to ABS sheets?

- Plastic sheets and ABS sheets have distinct properties and uses. ABS (Acrylonitrile Butadiene Styrene) sheets are a specific type of plastic sheet known for their excellent impact resistance and durability. They are commonly used in automotive parts, electronics, and toys due to their strength and ability to withstand heavy-duty applications. On the other hand, plastic sheets encompass a broader category and can include various materials such as acrylic, polycarbonate, and polyethylene. Each type of plastic sheet has its own unique characteristics and applications. While ABS sheets excel in impact resistance, other plastic sheets might offer superior optical clarity, chemical resistance, or flexibility. Ultimately, the choice between plastic sheets and ABS sheets depends on the specific requirements of the project or application at hand.

- Q: How do you paint gouache on a plastic board?

- Yes! If you are afraid of expensive, or acrylic paint is not easy to buy, you can add the right amount of white latex, white latex and paint mixing, after which the color unchanged, but dry faster

- Q: Can plastic sheets be used for lining ponds?

- Yes, plastic sheets can be used for lining ponds. These sheets, often made of heavy-duty polyethylene or PVC, are commonly used as pond liners to prevent water leakage and maintain the desired water level. They are easy to install, cost-effective, and provide a reliable barrier against seepage.

- Q: What's the difference between a TK board and a plastic board?

- KT is composed of a PS particle generation after foam plate core, a new type of material through the surface film pressure and a plate body, crisp, light, non perishable, easy processing, and can be directly on the screen plate printing (screen printing plate, paint (paint) to detect, adaptability) mounted cover back screen and widely used in printing, advertising promotion, building decoration, arts and packing etc..

- Q: Can plastic sheets be used for electrical circuit boards?

- No, plastic sheets cannot be used for electrical circuit boards. Circuit boards require materials with good electrical conductivity, heat resistance, and mechanical strength, which are qualities that plastic sheets typically do not possess.

- Q: Are plastic sheets durable?

- Yes, plastic sheets are generally durable. They are designed to be strong and resistant to impact, moisture, and UV radiation. However, the durability may vary depending on the specific type and thickness of the plastic sheet.

Send your message to us

Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords