Plastic Sheets - PVC Free Foam Board / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm,as your required

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

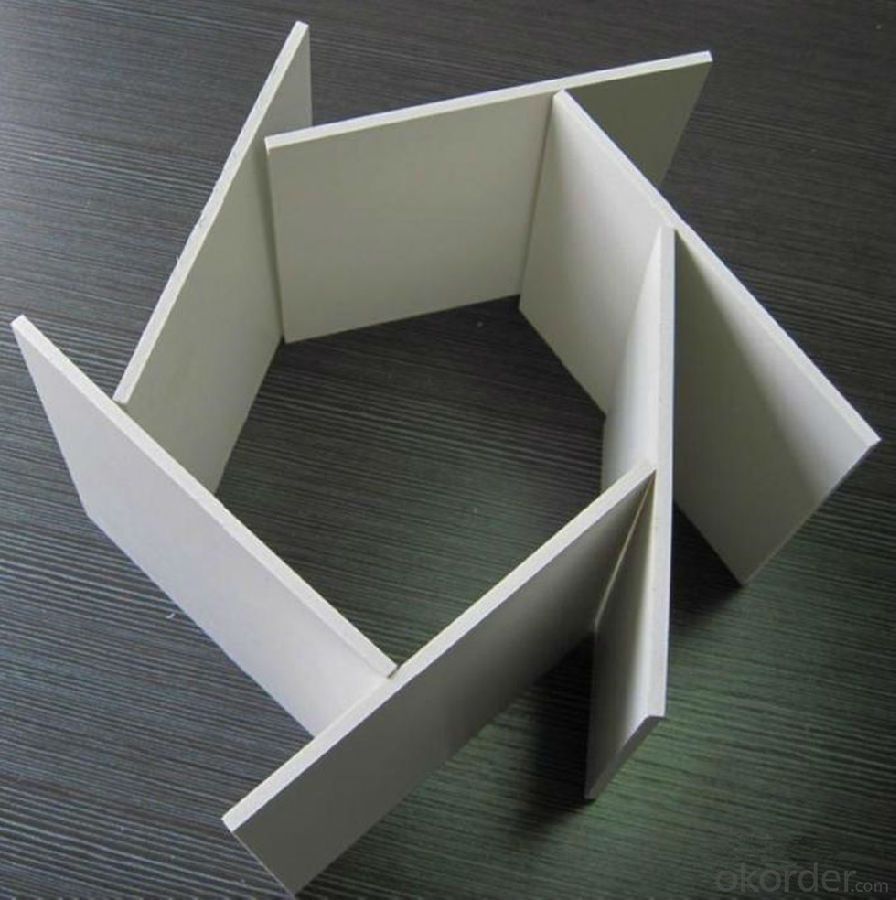

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.Additional customized properties

Impact strength/izod impact strength

corrosion-resistance

anti-aging

anti-UV

anti-static

high-temperature/low-temperature resistance

toughening

rigidity

foaming performance

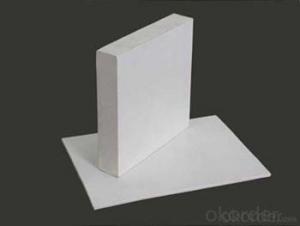

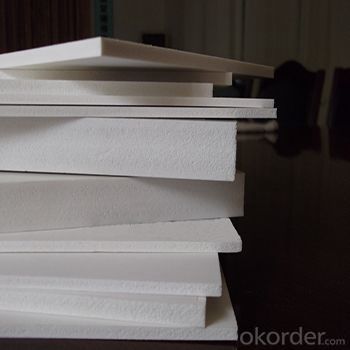

5. Pictures of PVC Foam Sheet

6.Pictures of Factory

- Q: What are the common uses of plastic sheets?

- Plastic sheets are commonly used in various applications such as packaging, construction, signage, and crafting. They can be used as protective covers, barriers, or dividers, and are also popular for creating durable and lightweight materials for displays, posters, and promotional items. Plastic sheets are versatile and can be molded, shaped, or cut to fit specific needs, making them widely utilized in many industries.

- Q: Can plastic sheets be used for chemical reaction vessels?

- No, plastic sheets are generally not suitable for use as chemical reaction vessels due to their limited resistance to chemical reactions and potential for leaching harmful substances into the reaction mixture. Glass or specialized materials such as borosilicate glass or certain types of stainless steel are typically preferred for chemical reaction vessels.

- Q: Are plastic sheets transparent or translucent?

- Plastic sheets can be both transparent and translucent, depending on their composition and thickness.

- Q: I got a protective plastic sheet, but every time I try to put it on, a million bubbles keep popping out.

- Unfortunately, it's not really possible to eliminate every bubble. Just put it on very slowly and try to rub them out as you go instead of trying to get them all at the end. Keep in mind that when the iPod is turned off, the bubbles look horrible but once it's turned on, you won't notice them nearly as much.

- Q: What are the bending capabilities of plastic sheets?

- The bending capabilities of plastic sheets depend on various factors such as the type of plastic, thickness, and temperature. Generally, plastic sheets can be easily bent or formed into various shapes when heated to their specific temperature range. This process is known as thermoforming. However, some plastics have higher rigidity and may require more heat or additional techniques like scoring or using a bending machine to achieve the desired bend.

- Q: Are plastic sheets resistant to chemicals used in agriculture?

- Yes, plastic sheets are generally resistant to the chemicals used in agriculture. They are designed to withstand exposure to various agricultural chemicals, such as pesticides, herbicides, and fertilizers, without degrading or being affected by them. However, it is important to check the specific type and quality of plastic sheeting to ensure it is compatible with the specific chemicals being used.

- Q: What is the purpose of using plastic sheets?

- The purpose of using plastic sheets is to provide a protective barrier or cover, whether it be for shielding against dust, water, or other elements. They can also be used for insulation, packaging, or as a barrier for construction or DIY projects.

- Q: Titanium sheet, lets say thickness 250 microns (0,010''), and size 3.5 x 2.5. How far could it bend so when you release it it goes back to its original shape (without any shape change or damage)? Could it act same as/close to a (plastic) playing card? Shuffle, bend half of the card when you are looking at it while its laying on the table?

- In alloyed condition it’s as strong as steel but 45% lighter and also ductile Under mentioned conditions, it will not behave as you mentioned

- Q: Can plastic sheets be used for DIY projects in home improvement?

- Yes, plastic sheets can be used for DIY projects in home improvement. They are versatile and can be used for various purposes such as creating protective barriers, insulating windows, making temporary partitions, or even constructing greenhouse structures. Plastic sheets are readily available, affordable, and can be easily cut or shaped to fit specific project requirements.

- Q: I'm looking for MINI DVD (3or8cm) carry case, wallet, organizer, plastic insert with 3 binder holes sheets !Can you help me, please ? I just can't find anywere.Thanks a lot.

- try in Bucharest, Muzica shop... or in other places in city...always are...

Send your message to us

Plastic Sheets - PVC Free Foam Board / PVC Sheet PVC Celuka Moulding

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords