Custom Printing Die Cut PVC Foam Board Sheet Sintra Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

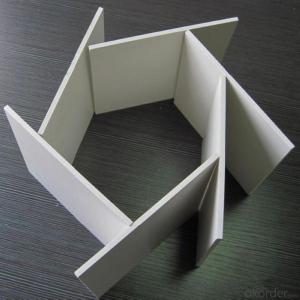

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Product Specification

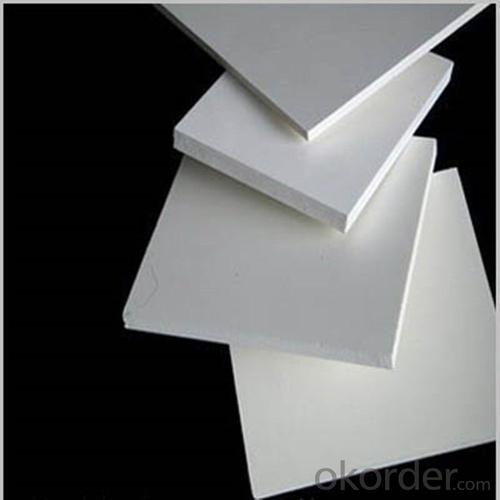

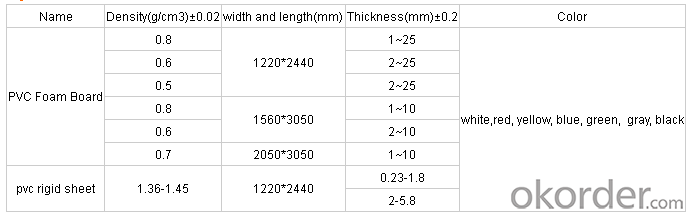

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Product Features

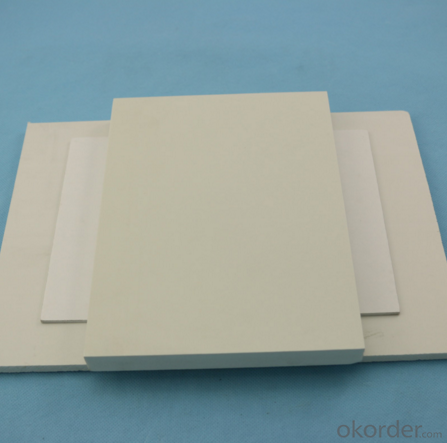

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

FAQ

1,How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect

2,Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

Product details

- Q: What is an extrusion plate?

- With high thermal resistance and low linear expansion ratio, the characteristics of the low, the obturator structure rate reached more than 99%, the formation of a vacuum layer, avoid air flow cooling, to ensure that the insulation performance of lasting and stable, relative to the closed cell foam polyurethane rate of 80%, the leading advantage is self-evident. Practice has proved that the insulation effect of 20mm thick XPS extruded insulation board is equivalent to that of 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is currently the best choice for building insulation.

- Q: I must be having a brain fart! I can't remember why I bought six rolls of duck tape and heavy gauge plastic sheeting. I remember that it had something to do with the Y2K scare but what the hell? Can someone refresh my memory, please?

- Water collector?

- Q: Are plastic sheets transparent or translucent?

- Plastic sheets can be both transparent and translucent, depending on their composition and thickness.

- Q: i use type 6 plastic[the plastic containers that salads normally come in] as shrink plastic to make shrinkydinks.but i was wondering is there another place to purchase it other than shrinkydinks?easy 10 points.

- I don't know about type 6 plastic. but you can buy 6 mil. plastic at most any hardware store, wal-mart or home improvment store.

- Q: Can plastic sheets be used for vacuum forming in the aerospace industry?

- Yes, plastic sheets can be used for vacuum forming in the aerospace industry. Vacuum forming is a widely used manufacturing process in aerospace for creating various components and parts. Plastic sheets, such as high-performance thermoplastics, are often used due to their lightweight, durable, and cost-effective nature. These plastic sheets are heated and then shaped over a mold using vacuum pressure, resulting in precise and complex aerospace components.

- Q: Are plastic sheets resistant to chemicals in swimming pools?

- Yes, plastic sheets are generally resistant to chemicals in swimming pools.

- Q: Can I silkscreen grafix to ABS plastic? On the haircell textured side?

- DO the usual, silkscreen to vinyl then overlay it on the plastic.

- Q: A square sheet of plastic measures 1 yard by 1 yard. Square pieces, each 5 inches by 5 inches, are cut from the plastic sheet. What percent of the plastic is wasted?Give your answer correct to one decimal place.A) 5.5%B) 3.6%C) 1.6%D) 0.3%

- You're going to cut out a 35x35 sheet from the 36x36 (36 * 36 - 35 * 35) / (36 * 36) = (1296 - 1225) / 1296 = 71 / 1296 = 0.05478395061728395061728395061728 5.4784% = 5.5% is wasted

- Q: Are plastic sheets resistant to discoloration from chemicals?

- Yes, plastic sheets are generally resistant to discoloration from chemicals.

- Q: i'm trying to decide which rainsuit to buy and i can't figure out what the difference is between the 2, I just don't see how 10mm or 20mm is right, i don't see a rainsuit being made out of 1cm or 2cm thick plactic.

- Ah, the twisted logic of sports statistics. For the sub to get the clean sheet hardly seems fair, especially if he played only a limited nunber of minutes. It strikes me that in order to get the credit for the shutout, the keeper needs to play a certain minimum time (60 minutes seems reasonable). Consider baseball stats: in order to be credited with a win, a starting pitcher must play at least five (of nine) innings and be leading when replaced. A sub coming in to close the game gets credited with a save, so both pitchers come away with something. Except save would be a confusing name for a goalkeeping stat.

Send your message to us

Custom Printing Die Cut PVC Foam Board Sheet Sintra Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords