Plastic Sheets - Green 2024 New Extrude PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

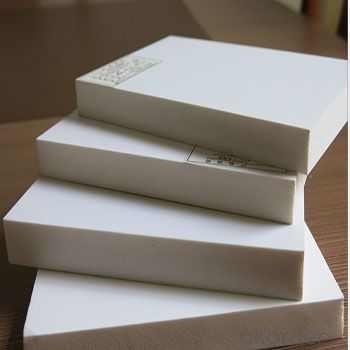

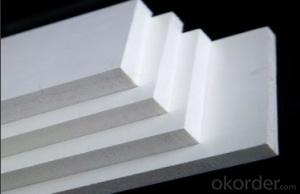

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Product name | PVC Foam Board | Raw Material | PVC | |

Size | 122*244,156*305,205*305cm | Thickness | 1-30mm | |

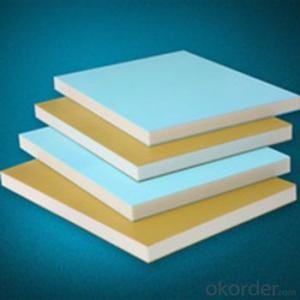

Color | White,blue,black,yellow,etc | Density | 0.35-0.9g/cm3 | |

Type | PVC Free Foam Board,PVC Crust Foam Board,Co-extrusion PVC Foam Board | |||

Tolerances | +/- 0.03 on densities -0 to +5mm on width | -0 to +10mm on length | ||

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

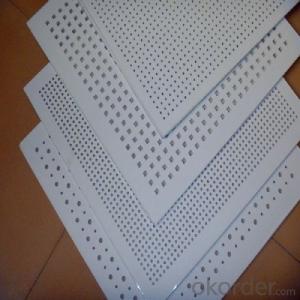

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.Product Pictures

- Q: Can plastic sheets be used for DIY partitions?

- Yes, plastic sheets can be used for DIY partitions. They are lightweight, affordable, and easy to cut and shape, making them a popular choice for creating temporary or semi-permanent partitions in various DIY projects.

- Q: What are the different finishes available for plastic sheets?

- Some of the different finishes available for plastic sheets include glossy, matte, textured, frosted, and embossed finishes.

- Q: i got a clothe, i don't think it's really plastic, it's kind of thick, a bit see through and looks a little bit like plastic, and sheet protectors , are they recyclable? thanks!

- Most plastics are recyclable. However, not all cities recycle anything, and in my city, only certain categories of plastic can go in my recycling bin. Look for a little triangular logo on the item, with arrows leading to each other, with a number or symbol in the middle. See my source. In my city, we are not supposed to put any plastic with that 7 in our bins, because the city waste disposal doesn't have the means to recycle it.

- Q: I am trying to imitate corrugated plastic (the translucent quality) but in a larger scale. Is there something you recommend I use? thanks!

- I have sprayed glass with a very light coat of cheap white spray paint, and it gives it the frosted look. I bet the same would apply to acrylic.

- Q: Are plastic sheets resistant to bending in extreme temperatures?

- Yes, plastic sheets are generally resistant to bending in extreme temperatures. However, the degree of resistance may vary depending on the specific type and composition of the plastic material.

- Q: What are the different types of plastic sheets available?

- There are numerous types of plastic sheets available, including acrylic, polycarbonate, PVC, ABS, HDPE, and LDPE. Each type has unique properties and characteristics that make them suitable for various applications such as signage, packaging, construction, and fabrication.

- Q: Where can i buy the PVC Sheet with good quality?

- I okorder .

- Q: Whenever I have sex, females ended u ejaculating... and its a lot! It obviously ruins my bed and causes unpleasantness after sex. I think I need to put on something to guard my mattress and bed sheet. How about plastic sheets? Where can I get them? Do you have any other suggestions?

- they actually sell them at walmart! they're not expensive at all, they sell them for people with allergies and people who have problems wetting the bed... they're in the same section as the rest of the sheets. they have the kind that can wash off with a wash cloth or the kind that have a cloth top like a regular sheet that is plastic underneath so it's not such a plasticy feeling on top when you sleep on it that you just throw in the washer when you need to wash it...

- Q: What are the most common applications for plastic sheets?

- Plastic sheets have a wide range of applications, but some of the most common ones include packaging materials, construction materials, signage, displays, automotive parts, electronic components, and medical devices.

- Q: Can plastic sheets be used for bird feeders?

- Yes, plastic sheets can be used for bird feeders. They can be easily shaped and molded into different sizes and designs, making them a versatile material for creating bird feeders. Additionally, plastic sheets are durable and weather-resistant, making them suitable for outdoor use.

Send your message to us

Plastic Sheets - Green 2024 New Extrude PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords