Plastic Sheets PVC Foam Board/Sheet Plastics Process Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

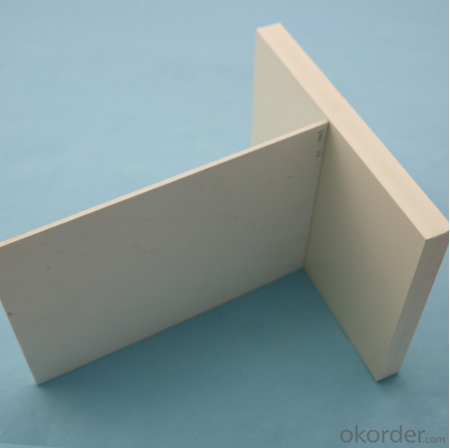

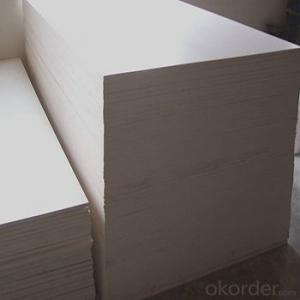

PVC foam sheet is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2.Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Usage life: more than 50 years

water absorption:<1.0%

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4.Product Application

①Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

②Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating,etc.

③Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

④Chemical anti corrosion project, special cold project, environmental protection.

5.pictures of factory

- Q: How do plastic sheets compare to polypropylene sheets?

- Plastic sheets and polypropylene sheets are actually the same thing. Polypropylene is a type of plastic, specifically a thermoplastic polymer. So, when comparing plastic sheets to polypropylene sheets, they are essentially the same material.

- Q: You know like 'pexiglas' or what ever. I need Something simular to that. Maybe .5 in or around there for the thickness. What could i Use?

- How large a piece do you need? Could you take a piece of canvas and glue plastic on one or both sides?? Also, you can buy plastic sheets for a bed (to prevent soiling the mattress)--glue some of those together.?? Or glue some tarps together?? Maybe plastic doesn't glue??

- Q: I have a large sheet of plastic, or I think its plastic. Its about 1/8 inch thick, knubby on one side, smooth on the other and slightly pliable. I'd like to cut equal size panels to fit into my window shutters. I tried using a glass cutter and T square but that didn't work. Any suggestions?

- Use a Stanley knife. With a straight edge, score the smooth side several times. Now lay the sheet on a table with the score line right at the edge. Have a second person press down with a board on top of table to keep sheet from moving. (Place board right at edge) Person one now presses down on sheet to snap. Do it in one quick move.

- Q: Are plastic sheets resistant to discoloration from sunscreens?

- Yes, plastic sheets are generally resistant to discoloration caused by sunscreens.

- Q: Do plastic sheets have any impact on the environment?

- Yes, plastic sheets do have an impact on the environment. They are typically made from non-biodegradable materials, such as polyethylene or PVC, which can take hundreds of years to break down. When not properly disposed of, plastic sheets can contribute to pollution, including landfills and oceans. Additionally, the production of plastic sheets often involves the use of fossil fuels and harmful chemicals, which further contribute to environmental degradation.

- Q: Not too floppy, strong but flexible plastic stuff. (for use around pet cage to keep bedding in)Online / in store UK?

- You okorder . It is engaged in manufacturing and supplying best quality range of plastic sheets and tarpaulins.

- Q: Can plastic sheets be used for machine covers?

- Yes, plastic sheets can be used for machine covers. They provide a protective barrier against dust, debris, and moisture, helping to preserve the machine's integrity and functionality. Plastic sheets are lightweight, durable, and easy to install, making them a cost-effective solution for machine coverings.

- Q: Are plastic sheets suitable for electrical enclosures?

- Yes, plastic sheets are suitable for electrical enclosures. They are non-conductive and can provide insulation and protection for electrical components. Additionally, plastic sheets are often lightweight, durable, and resistant to corrosion, making them a popular choice for various electrical enclosure applications.

- Q: What are the thermal conductivity properties of plastic sheets?

- The thermal conductivity properties of plastic sheets are relatively low compared to other materials such as metals. This means that plastic sheets are generally good insulators and tend to have poor heat transfer capabilities. However, the thermal conductivity of plastic sheets can vary depending on the specific type of plastic used and its composition.

- Q: Those yellow sheets of plastic or something that you cut your design into and then stick to the silk screen? what are they called i need to buy more.....

- polyethylene sheets... i don't even know what silk screening is but there's a little thing called Google. duh...

Send your message to us

Plastic Sheets PVC Foam Board/Sheet Plastics Process Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords