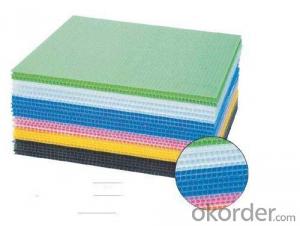

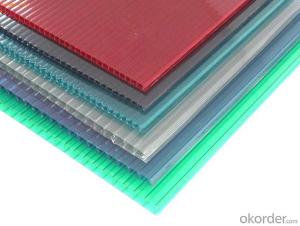

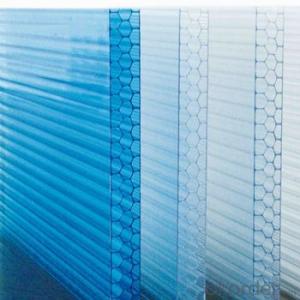

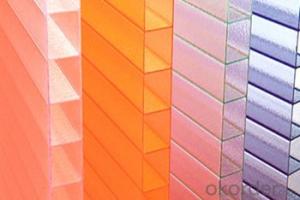

Plastic Sheets - Cmax Triple-Wall Hollow Polycarbonate Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000m2 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Features:

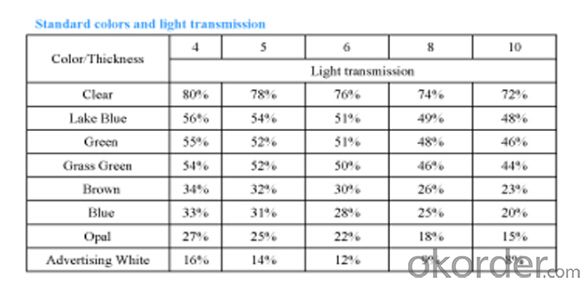

1. High light Transmisstion

2. Anti- Broken

3. Anti - Sunshine

4. UV protection

5. Easy Clean

6. Easy Installation

7. Long life Time (Up to 10 years under standard circumstance)

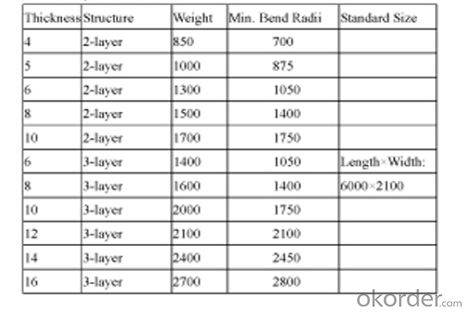

Specifications:

- Q: What are the advantages of using plastic sheets?

- There are several advantages of using plastic sheets. Firstly, they are lightweight and easy to handle, making them convenient for transportation and installation. Additionally, plastic sheets are highly durable and resistant to impact, moisture, and corrosion, making them suitable for various applications. They also offer excellent thermal insulation and soundproofing properties, enhancing energy efficiency and reducing noise pollution. Furthermore, plastic sheets are inherently flexible and can be easily molded into different shapes, allowing for versatile and creative uses in industries such as construction, packaging, and automotive.

- Q: What are the different ways to join plastic sheets together?

- There are several different ways to join plastic sheets together, including adhesive bonding, thermal welding, mechanical fastening, solvent welding, and ultrasonic welding.

- Q: Can plastic sheets be used for automotive applications?

- Yes, plastic sheets can be used for automotive applications. They are commonly used for creating interior and exterior parts such as dashboards, door panels, and body panels. Plastic sheets offer advantages such as being lightweight, durable, and resistant to corrosion, making them suitable for automotive use.

- Q: it touched a plastic bag right when it came out of the oven and now it's stuck on and hard as a rock. how do i get it off?

- the only thing i can think of is freezing it trying to see if it'll pop off. Otherwise, just buy a new cookie sheet, lol!

- Q: I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- You should really use mold retardant sheetrock in the basement. It might actually be required by code depending on where you live. I helped a guy fix up a house and the inspector told him to sheetrock the ceiling of the basement and use 1/2 mold resistant sheetrock. The differences you get with thickness of sheetrock is mostly durability. Obviously thicker sheetrock will hold up longer. On ceilings especially, the 3/8 inch sheetrock will bend over time between the rafters (or floor joists in the basement) where it is screwed in. There is also a difference in sound-proofing, you hear less through walls of 5/8 than 3/8. The last difference is fire resistance, 5/8 inch sheetrock takes significantly longer for fire to burn through than 3/8. To chose which one you want to use, find out what the code requires in your area. You may be required to use mold resistant sheetrock, or you may be required to use fire resistant boards. I would use 1/2 in the basement because it is a lot easier to hang than 5/8 and you have decent durability and unlike 3/8, it will not bend or bow over time. I actually saw mold resistant fiber tape for the joints in The Home Depot, you might want to use that whether or not it's required by code just for extra measure. Some things may be more expensive to do to the tee, but if you cheap out now, you may end up pending more fixing things if they go wrong or get messed up later down the road. And most importantly, do every single thing to code and pull permits for everything, that way you are covered on all your bases.

- Q: Can plastic sheets be used for protective barriers in healthcare settings?

- Yes, plastic sheets can be used as protective barriers in healthcare settings. They can be easily cleaned and disinfected, provide a physical barrier against droplets and other contaminants, and are commonly used in various healthcare settings such as hospitals, clinics, and pharmacies.

- Q: Are plastic sheets flammable?

- No, plastic sheets are generally not flammable.

- Q: We're building a crude mock yacht for a party of some sorts and we want to imitate the shininess by wrapping shiny white bendable plastic sheets around the outside of the wood frame. Does anyone know what I should use and where I can get it?

- You Can buy sheets called FRP panels at Home Depot for about 18-20 dollars per 8x4 sheet . FRP = fiberglass reinforced panel

- Q: Plastic NPP board, there is no poison?

- If it is made of polypropylene, the cup is non-toxic and the processing temperature (DEG) is 180~240. So boiling water doesn't break it down.

- Q: Can plastic sheets be used for outdoor furniture?

- Yes, plastic sheets can be used for outdoor furniture. They are durable, weather-resistant, and low-maintenance, making them suitable for outdoor use. Additionally, plastic sheets can be easily shaped and molded, allowing for various designs and styles in outdoor furniture.

Send your message to us

Plastic Sheets - Cmax Triple-Wall Hollow Polycarbonate Sheet

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 50000m2 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords