Plastic Formwork Concrete Formwork Scaffolding Types and Names Scaffolding Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Scaffolding Types and Names Scaffolding Company CNBM

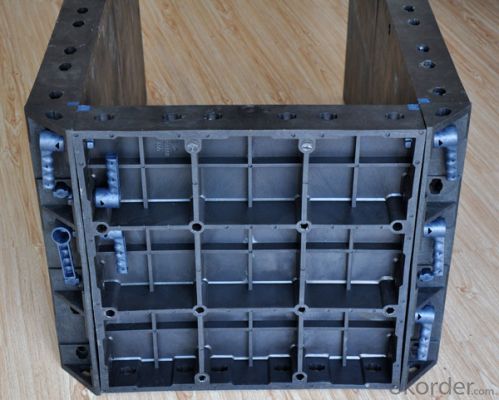

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

We have organized several common questions for our clients,may help you sincerely:

How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Why the floor is not plastic building materials square wood and template

- Must be strong and durable, the environment is bad, need to find strong

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Europe and the United States national construction template is made of plastic or wood

- Although the problem is not understand the landlord can not help.

- Q: Types of building templates? What is the water template?

- Building a template, the use of rear surface roughness is better, do not need to deal with the second. Provincial workers, time-saving.

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

Plastic Formwork Concrete Formwork Scaffolding Types and Names Scaffolding Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords