Plastic Formwork Concrete Formwork Household Scaffolding Stage Scaffolding New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1300 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork Household Scaffolding Stage Scaffolding New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

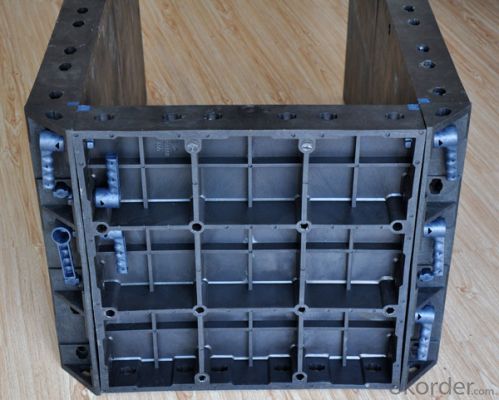

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

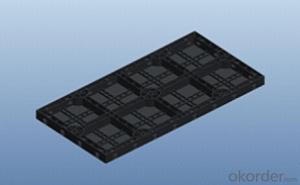

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- With PVC board and steel ceiling of the board on it, to the hardware store to buy

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

Plastic Formwork Concrete Formwork Household Scaffolding Stage Scaffolding New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1300 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords