Plastic Formwork Concrete Formwork A Frame Scaffolding Scaffolding Joint Pin Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1400 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork Concrete Formwork A Frame Scaffolding Scaffolding Joint Pin Made in China

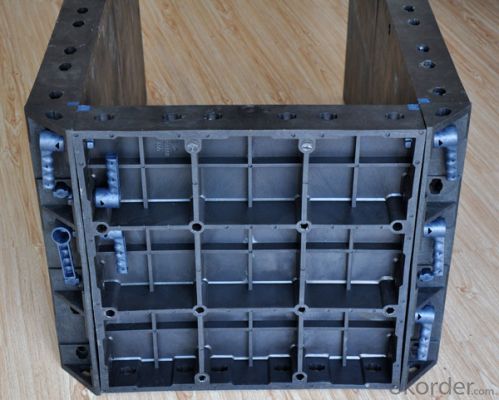

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

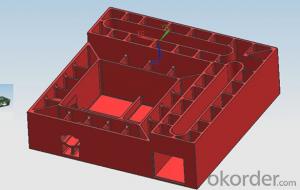

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

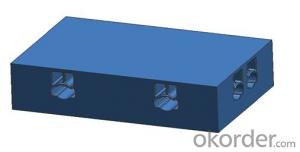

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Stupid way, with a little hammer little bit of the beat, out a little less a little bit.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- With PVC board and steel ceiling of the board on it, to the hardware store to buy

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- In summary, what template to use depends on what your structure needs.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

Send your message to us

Plastic Formwork Concrete Formwork A Frame Scaffolding Scaffolding Joint Pin Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1400 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords