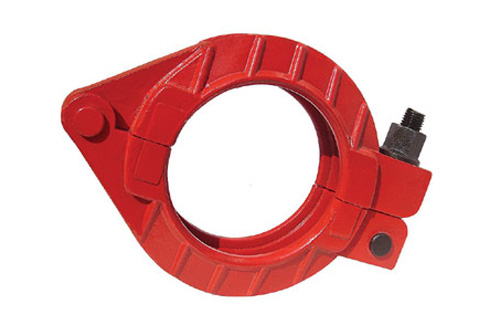

Pipeline Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Size: 2"-8" (DN50-DN200)

Brand: Putzmeister, Schwing, Sany

Series: Screw Coupling, Bolt Coupling, SnapCoupling

Other products:

1) Putzmeister/ Schwing/ Zoomlion/ SermacRam Pistons

2) Putzmeister/ IHI/ Kyokuto/ Zoomlion/ SanySeperated Piston

3) Wear-resisting board and Cuts ink

4) Rubber hose

5) ST52 steel pipe, elbow, reducer

6) Cleaning seriesand others- Q: How often should hopper grate clamps be inspected or replaced in a concrete pump?

- Hopper grate clamps in a concrete pump should be inspected regularly, preferably on a monthly basis, to ensure they are in proper working condition. However, the frequency of inspection may vary depending on the usage and operating conditions of the concrete pump. If the concrete pump is used extensively or subjected to harsh environments, more frequent inspections may be necessary, such as every two weeks or even weekly. On the other hand, if the pump is used less frequently or operates in less demanding conditions, inspections can be done less frequently, such as every two to three months. The purpose of these inspections is to identify any signs of wear, damage, or deterioration in the hopper grate clamps. Any loose or worn-out clamps should be promptly replaced to prevent accidents or disruptions during concrete pumping operations. It is crucial to prioritize safety and ensure that the hopper grate clamps are in good condition to secure the hopper grate effectively and prevent any unwanted material spillage. Regular inspections and timely replacements of hopper grate clamps will help maintain the efficiency and reliability of the concrete pump, ensuring uninterrupted operation and minimizing the risk of any potential issues.

- Q: What are the advantages of using carbon fiber components in concrete pump spare parts?

- There are several advantages of using carbon fiber components in concrete pump spare parts. Firstly, carbon fiber is extremely lightweight yet incredibly strong, which allows for reduced weight and increased durability of the spare parts. This not only makes them easier to handle and transport, but also enhances their overall performance and longevity. Secondly, carbon fiber has a high resistance to corrosion and chemicals, making it highly suitable for use in concrete pumping applications where exposure to various substances is common. This significantly extends the lifespan of the spare parts, reducing maintenance and replacement costs in the long run. Additionally, carbon fiber components offer improved fatigue and impact resistance, ensuring they can withstand the demanding conditions and high stresses involved in concrete pumping operations. This enhances the reliability and safety of the equipment, minimizing the risk of failure or breakdown during use. Furthermore, carbon fiber has excellent thermal and electrical insulation properties, reducing heat transfer and the risk of electrical conductivity. This makes it ideal for use in concrete pump spare parts that operate in extreme temperatures or are exposed to electrical currents, enhancing their overall performance and safety. In summary, the advantages of using carbon fiber components in concrete pump spare parts include lightweight yet strong construction, high resistance to corrosion and chemicals, improved fatigue and impact resistance, as well as enhanced thermal and electrical insulation properties.

- Q: Are there any specific tools or equipment required for the installation of concrete pump spare parts?

- Yes, there are specific tools and equipment required for the installation of concrete pump spare parts. Some common tools include wrenches, socket sets, screwdrivers, hammers, and pliers. Additionally, specialized equipment like cranes, lifters, and hoists may be needed for lifting and positioning heavy components. It is important to use the appropriate tools and equipment to ensure proper installation and safety.

- Q: What are the indications of a worn-out concrete pump clamp?

- Some indications of a worn-out concrete pump clamp may include visible cracks or damage on the clamp, difficulty in tightening or loosening the clamp, leaking of concrete or water from the connection area, and decreased performance or efficiency of the pump due to inadequate sealing.

- Q: What are the signs of a faulty concrete pump control box?

- There are several signs that may indicate a faulty concrete pump control box. These signs can vary depending on the specific issue, but some common signs include: 1. Unresponsive controls: One of the most obvious signs of a faulty control box is when the controls become unresponsive or fail to function properly. This may include buttons that do not work, switches that do not engage, or a lack of response when adjusting settings. 2. Inaccurate readings: Another sign of a faulty control box is when the readings or measurements displayed on the control panel are inaccurate or inconsistent. This may include incorrect pressure readings, flow rates, or other important measurements necessary for proper pump operation. 3. Electrical issues: Faulty control boxes can also cause electrical problems such as flickering lights, sudden power surges or shortages, or even blown fuses. These electrical issues can be dangerous and may lead to further damage if not addressed promptly. 4. Strange noises: When a control box is faulty, it may produce strange noises, such as buzzing, humming, or clicking sounds. These noises can indicate loose connections, damaged components, or malfunctioning parts within the control box. 5. Pump malfunctions: A faulty control box can also cause the concrete pump itself to malfunction. This may include issues such as inconsistent pumping, irregular flow, or sudden stops and starts. These problems can disrupt the concrete pouring process and potentially lead to project delays. If you suspect a faulty concrete pump control box, it is crucial to address the issue promptly. It is recommended to consult a qualified technician or contact the manufacturer for assistance in diagnosing and repairing the control box.

- Q: How long does it take to receive concrete pump spare parts after placing an order?

- The time it takes to receive concrete pump spare parts after placing an order can vary depending on several factors. Firstly, it depends on the availability of the specific spare parts you have ordered. If the parts are readily available in stock, the delivery time can be relatively quick. However, if the parts are not in stock and need to be manufactured or sourced, it may take longer to receive them. Secondly, the location and distance between the supplier and your location also play a role in the delivery time. If the supplier is in close proximity, the parts can be delivered within a few days. However, if the supplier is located far away or in a different country, it may take longer due to shipping and customs processes. Furthermore, the shipping method you choose can also impact the delivery time. Expedited shipping options can ensure quicker delivery, but at an additional cost. Standard shipping methods may take longer but are usually more cost-effective. Lastly, the efficiency and responsiveness of the supplier also come into play. A reliable supplier with a streamlined ordering and shipping process will likely be able to deliver the spare parts in a shorter time frame. In conclusion, the time it takes to receive concrete pump spare parts after placing an order can vary based on factors such as availability, location, shipping method, and supplier efficiency. It is advisable to inquire about estimated delivery times when placing the order to have a better understanding of when the parts will be delivered.

- Q: How often should hopper cylinder seals be replaced in a concrete pump?

- Hopper cylinder seals in a concrete pump should be replaced as soon as signs of wear or damage are observed. Regular inspection and maintenance can help identify the need for replacement, but the frequency ultimately depends on factors like usage, environmental conditions, and the quality of the seals. It is recommended to follow the manufacturer's guidelines and consult with professionals to determine the appropriate replacement schedule for hopper cylinder seals in a concrete pump.

- Q: What is the function of a concrete pump control box?

- A concrete pump control box is an essential component of a concrete pump system. Its function is to control and manage the operation of the concrete pump, ensuring a safe and efficient pumping process. The control box allows the operator to start, stop, and adjust the pumping speed of the concrete pump. It typically contains various control switches, knobs, and buttons that are used to control different aspects of the pumping process. One of the main functions of the control box is to monitor the pressure and flow of the concrete being pumped. This information is crucial in ensuring that the concrete is being pumped at the desired rate and consistency. The control box also alerts the operator if there are any abnormalities or issues with the pumping system, such as clogs or blockages. Additionally, the control box may have features like emergency stop buttons and safety interlocks to ensure the safety of both the operator and the equipment. It may also include indicators and alarms to provide visual and audible cues about the status of the pump and any potential issues that may arise. In summary, the function of a concrete pump control box is to provide the operator with the necessary controls and information to safely and efficiently operate the concrete pump. It ensures proper monitoring, control, and safety of the pumping process, ultimately leading to successful concrete placement.

- Q: How is a concrete pump pipe different from a regular pipe?

- A concrete pump pipe is specifically designed to be used in concrete pumping applications, whereas a regular pipe is more commonly used for general plumbing purposes. Concrete pump pipes are typically made of high-quality and durable materials to withstand the high pressure and abrasive nature of pumped concrete. They also have specialized ends, such as flanges or couplings, to provide a secure connection between the pump and the delivery system. In contrast, regular pipes may come in various materials and sizes, depending on their intended use in plumbing systems.

- Q: Can concrete pump spare parts be tested for performance and quality before installation?

- Yes, concrete pump spare parts can be tested for performance and quality before installation. This is typically done to ensure that the parts meet the required specifications and standards, reducing the risk of any potential issues or failures during operation. Testing can involve various methods such as performance testing, stress testing, durability testing, and quality control checks to ensure optimal performance and reliability of the spare parts.

Send your message to us

Pipeline Clamp

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords