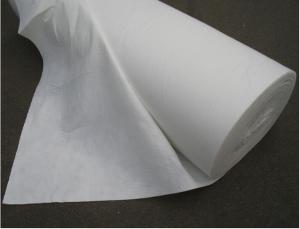

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

1. Specifications of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

Specifications: 100gsm-800gsm

Width: 1-6m

Length: 50-100m or as request

Property: good flexibility, permeability, filtration, separation and easy for consturction

2. Technicial Data of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

No. | Item | Specification | Note | ||||||||||

Mass per square meter g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | ||

1 | Weight Variation % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and CD |

5 | Elongation at Break % | 25 ~ 100 | |||||||||||

6 | CBR Mullen Burst Strength KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size 090 mm | 0.07 ~ 0.2 | |||||||||||

8 | Vertical Permeability Coefficient cm/s | k× (0.1 ~ 0.001) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD and CD |

Needle punched geotextile after treatment method | |||||||||||||

3. Packing of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

4. Application of Needle Punched Short Fiber Nonwoven Polyester Geotextile 100g for Construction Use

In the area of highway, railway, dam, reclamation for filtration, separation drainage and protection.

- Q: Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. Geotextiles are commonly used in these projects to stabilize and reinforce soil, control erosion, and promote vegetation growth, ultimately enhancing the overall success and durability of the reclaimed land.

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q: Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q: Can geotextiles be used in coastal revetment projects?

- Yes, geotextiles can be used in coastal revetment projects. Geotextiles are commonly used in these projects to provide erosion control, stabilize the soil, and enhance the overall performance and longevity of the revetment system. They can help to prevent the loss of sediment, reduce wave energy, and provide stability to the structure by acting as a barrier between the soil and water.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are commonly used to stabilize slopes, reinforce soil, and control erosion in various construction projects. In coastal areas, they can be employed to prevent erosion of beaches, dunes, or shorelines by acting as a barrier against the movement of sediment and soil. Geotextiles provide an effective solution for coastal erosion control structures due to their permeability, strength, and ability to withstand harsh environmental conditions.

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, or drain soils in various construction applications. In the case of agricultural ponds, geotextiles can be used to prevent soil erosion, stabilize slopes, and provide protection against punctures or tears in the pond lining. Additionally, geotextiles can help improve water quality by filtering out sediment and contaminants from runoff water entering the pond.

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to the soil. They are used to reinforce the soil layers, prevent erosion, and improve drainage, thereby enhancing the overall stability of the slope.

- Q: What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q: How are geotextiles affected by mechanical stress?

- Geotextiles are significantly affected by mechanical stress as they undergo deformation and potential damage due to external forces or loads. The stress can cause the geotextile to stretch, tear, or even rupture, affecting its overall performance and functionality. Therefore, it is essential to consider the mechanical stress factors when designing or implementing geotextile applications to ensure their long-term durability and effectiveness.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Permeable Needle Punched Short Fiber Nonwoven Polyester Geotextile Membrane 100g for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords