Perforated Color Coater Aluminium Coil for ACP Panel Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coater Aluminium Coil for ACP Panel Building

Material | Alloy Aluminum 1XXX,3XXX,5XXX or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating,PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coater Aluminium Coil for ACP Panel Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coater Aluminium Coil for ACP Panel Building

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

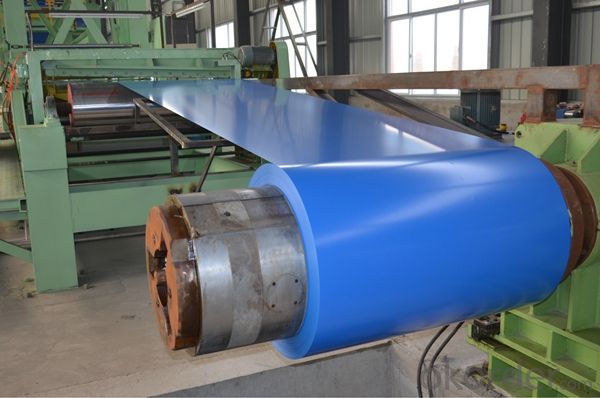

5. Image of Color Coater Aluminium Coil for ACP Panel Building

6. Package and shipping of Color Coater Aluminium Coil for ACP Panel Building

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to create baskets or containers using aluminum coils?

- <p>Yes, aluminum coils can be used to make baskets or containers. Aluminum is a lightweight, durable, and malleable material that can be easily shaped and bent into various forms. It is commonly used in manufacturing due to its strength and resistance to corrosion. For baskets or containers, aluminum coils can be woven or molded into the desired shape, offering both functionality and aesthetic appeal. However, it's important to consider the thickness and gauge of the aluminum to ensure the structure's stability and durability for its intended use.</p>

- Q: Are aluminum coils suitable for marine environments?

- Aluminum coils are suitable for marine environments due to their excellent corrosion resistance properties. Aluminum has a natural oxide layer that forms on its surface, providing a protective barrier against saltwater corrosion. This makes aluminum coils highly resistant to rust and deterioration caused by exposure to marine conditions. Moreover, aluminum is lightweight, making it a preferred choice for marine applications where weight reduction is essential. Additionally, aluminum coils offer good thermal conductivity, which is beneficial for dissipating heat in marine cooling systems. Overall, aluminum coils are a reliable and durable choice for marine environments, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Can aluminum coils be recycled?

- Indeed, it is possible to recycle aluminum coils. Due to its exceptional recyclability, aluminum stands as one of the frequently recycled materials. The procedure for recycling aluminum coils encompasses melting them to eliminate impurities and subsequently molding them into fresh products or coils. By recycling aluminum coils, not only are natural resources preserved, but also energy consumption and greenhouse gas emissions are diminished relative to the production of new aluminum from primary materials.

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in the construction of heat exchangers, which are essential components in wastewater treatment plants. Heat exchangers are used to transfer heat from the wastewater to the treatment process, helping to optimize the treatment efficiency and reduce energy consumption. Aluminum coils are preferred in some cases due to their excellent thermal conductivity, lightweight, and resistance to corrosion, making them suitable for the harsh environment of wastewater treatment plants. Additionally, aluminum coils are cost-effective and have a long lifespan, making them a reliable choice for use in wastewater treatment facilities.

- Q: What are the different surface treatments available for aluminum coils?

- There are several surface treatments available for aluminum coils, each with its own benefits and applications. Some of the common surface treatments include: 1. Mill Finish: This is the standard untreated surface of aluminum coils. It has a dull appearance and is suitable for applications where aesthetics are not a priority, such as industrial or structural uses. 2. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum coils. This treatment enhances the corrosion resistance, durability, and appearance of the coils. Anodized aluminum coils are commonly used in architectural applications, such as building exteriors or window frames. 3. Paint Coating: Aluminum coils can be coated with various paints to improve their appearance, protect against corrosion, and provide additional functionality such as heat reflection or insulation. Paint coatings can be applied in different thicknesses and finishes, ranging from standard coatings for general use to specialized coatings for specific applications like automotive or aerospace industries. 4. Brushed Finish: This treatment involves brushing the surface of aluminum coils with abrasive materials to create a textured finish. Brushed aluminum coils have a distinct pattern and are often used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or improve their functionality. The embossing process alters the surface of the coils, creating a raised or recessed design. Embossed aluminum coils are commonly used in architectural, automotive, or packaging applications. 6. Laminating: Aluminum coils can be laminated with various materials, such as films or foils, to provide additional protection, insulation, or decorative effects. This treatment can enhance the appearance, durability, or functionality of the coils, depending on the type of laminating material used. These are just a few examples of the surface treatments available for aluminum coils. The choice of treatment depends on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, or functionality. It is important to select the appropriate surface treatment to ensure the desired performance and longevity of the aluminum coils in their intended use.

- Q: How do I write ionic formula for Sodium Aluminum Silicate? Please explain in a easy way ,,,,,,,,,,,,

- There are literally thousands of different kinds of sodium aluminum silicate, and they do not have simple formulas, because the aluminum and silicon form giant oxygen bridged anions. Most clay minerals are of this type, more or less, although potassium is more common in clays than sodium. So there is no easy way. The empirical formula is sometimes written as a ratio of Na2O to Al2O3 to SiO2, but this gives no information about the structure, only the overall composition. Look up clay minerals online. Wikipedia might be a good start. Also the website mentioned in the other answer.

- Q: Are aluminum coils suitable for heat sinks?

- Indeed, aluminum coils are well-suited for heat sinks. The reason for aluminum's popularity in this regard lies in its exceptional thermal conductivity and affordability. Its remarkable thermal conductivity permits efficient heat transfer from a heat source to the heat sink's fins, which effectively dissipate the heat into the surrounding environment. Moreover, aluminum possesses the advantageous qualities of being lightweight and easily moldable into different shapes, thereby rendering it a versatile material for heat sink purposes. All in all, aluminum coils prove to be a fitting option for heat sinks due to their ability to effectively dissipate heat and their cost-effectiveness.

- Q: What is the typical lead time for manufacturing aluminum coils?

- The typical lead time for manufacturing aluminum coils can vary depending on various factors such as the complexity of the order, the quantity required, and the current demand in the market. However, on average, it can range from a few weeks to a couple of months.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

- Q: The user is asking if it's safe to use aluminum coil for food preparation in a microwave oven.

- <p>No, you should not use aluminum coil for food preparation in a microwave oven. Aluminum is a metal and can cause sparks or even a fire when exposed to the microwave's electromagnetic field. It can also reflect microwaves, potentially damaging the oven. Always use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers for food preparation in a microwave.</p>

Send your message to us

Perforated Color Coater Aluminium Coil for ACP Panel Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords