Mill Finished PE Coated Aluminum Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished PE Coated Aluminium Composite Panel Description

Mill Finished PVDF Coated Aluminium Composite Panel is one semi-finished aluminium material. It can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PE Coated Aluminium Composite Panel

Mill Finished PE Coated Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished PE Coated Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PE Coated Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PE Coated Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

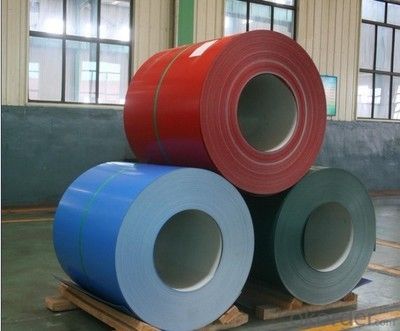

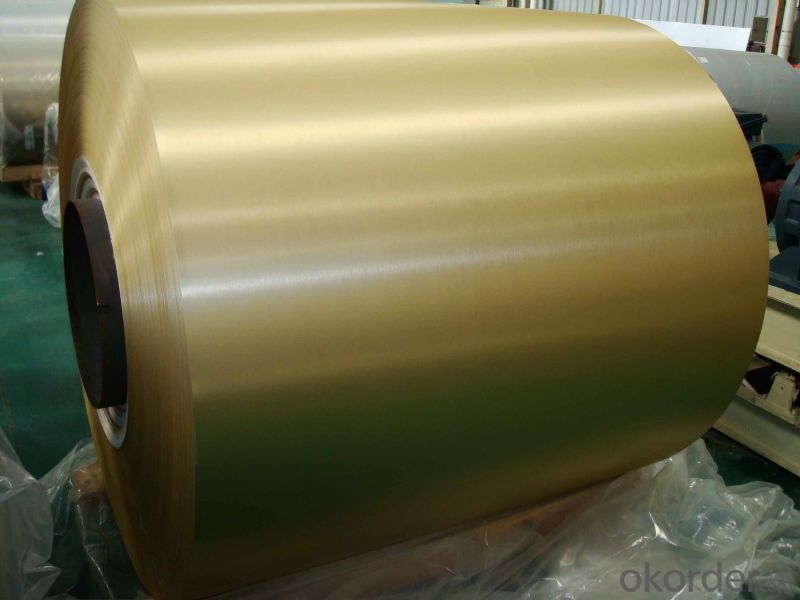

6. Image of Mill Finished PE Coated Aluminium Composite Panel

7. Package and shipping of Mill Finished PE Coated Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion. Aluminum is known for its durability and ability to withstand wear and tear. It has a high strength-to-weight ratio and excellent corrosion resistance properties, making it suitable for various applications where abrasion resistance is required. Additionally, aluminum coils are often coated or treated with protective finishes, further enhancing their resistance to abrasion. However, the specific level of resistance may vary depending on the specific alloy and the surface treatment applied to the coils.

- Q: Can aluminum coils be used in the production of electrical cables?

- Yes, aluminum coils can be used in the production of electrical cables. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity and lightweight properties. Aluminum coils are commonly used to manufacture power cables, building wires, and other electrical conductors. They have been proven to be a cost-effective alternative to copper coils, which are more expensive but possess higher electrical conductivity. The use of aluminum coils in electrical cables can help reduce the overall weight of the cables, making them easier to install and handle. Additionally, aluminum coils have good corrosion resistance, making them suitable for outdoor and underground applications. However, it is important to note that aluminum has a lower tensile strength compared to copper, so proper design considerations and installation techniques must be taken into account to ensure the longevity and reliability of aluminum-based electrical cables.

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It allows for efficient heat transfer and is often preferred over other materials like copper in certain HVAC applications.

- Q: Can aluminum coils be used in the production of electrical conductors?

- Aluminum coils are indeed applicable in the production of electrical conductors due to the fact that aluminum is an exceptional electricity conductor. It possesses approximately 61% conductivity in comparison to copper and boasts advantageous features such as lightness, cost-effectiveness, and a high melting point, rendering it suitable for a variety of electrical uses. Power transmission lines, electrical cables, and transformer windings are frequently made using aluminum coils. Nevertheless, it is important to take into account that aluminum possesses a lower tensile strength than copper, which may necessitate a greater cross-sectional area to accomplish the same level of electrical conductivity. Moreover, to guarantee long-term performance and prevent oxidation, additional surface treatments or coatings may be required for aluminum coils.

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Aluminum coils come with limitations and restrictions that need to be taken into account. Some of the key limitations are as follows: 1. Corrosion: Aluminum is prone to corrosion, especially when exposed to certain chemicals or environments. This means it may not be suitable for applications where it will encounter corrosive substances or highly corrosive environments. 2. Strength: Although aluminum is lightweight, it lacks the strength of metals like steel. This limits its use in applications requiring high strength or load-bearing capabilities. 3. Temperature sensitivity: Aluminum has a lower melting point compared to other metals, which can be a drawback in applications involving high temperatures. It may not be suitable for certain industrial or high-temperature environments. 4. Electrical conductivity: While aluminum has good electrical conductivity, it falls short of copper's conductivity. This can limit its use in applications requiring high electrical conductivity, such as electrical wiring or power transmission. 5. Cost: Aluminum can be more expensive than other metals, making it less favorable in cost-sensitive applications. In such cases, alternative materials may be preferred. 6. Formability: Compared to some other metals, shaping or forming aluminum coils can be challenging. This restricts their use in applications that demand complex shapes or tight tolerances. When selecting aluminum coils for a specific purpose, it is crucial to consider these limitations and restrictions. A careful evaluation of the particular requirements and constraints will help determine whether aluminum coils are suitable or if alternative materials should be considered.

- Q: How do aluminum coils compare to steel coils?

- The characteristics of aluminum coils and steel coils distinguish them in terms of strength, weight, corrosion resistance, and cost. Strength-wise, steel coils generally exhibit a higher tensile strength compared to aluminum coils. This means that steel coils can endure greater stress and pressure without deforming or fracturing. Nonetheless, aluminum coils retain sufficient strength for various applications and can be reinforced or designed for specific purposes. Weight plays a significant role in the comparison between aluminum and steel coils. Aluminum is a lightweight metal, weighing approximately one-third of steel. This lightweight property grants aluminum coils an advantage in applications where reducing weight is crucial, such as in transportation industries or aerospace. Regarding corrosion resistance, aluminum coils surpass steel coils. Aluminum naturally develops a protective oxide layer that prevents further corrosion. Conversely, steel is prone to rust and necessitates additional coating or treatment to enhance its corrosion resistance. This makes aluminum coils the preferred choice in coastal or humid environments where corrosion poses a significant concern. Cost is another vital factor to consider. Aluminum coils often entail a higher initial cost than steel coils due to the elevated cost of raw materials and manufacturing processes. Nevertheless, the overall cost may fluctuate depending on variables like transportation, maintenance, and lifespan. Aluminum coils tend to have lower maintenance costs and longer lifespans due to their corrosion resistance, which can offset the initial investment in the long run. In conclusion, aluminum coils provide several advantages over steel coils, such as lower weight, superior corrosion resistance, and potential long-term cost savings. However, steel coils still boast higher tensile strength and may be the preferred choice in applications that require maximum strength or have a restricted budget. Ultimately, the selection between aluminum and steel coils hinges on the specific requirements and considerations of the intended application.

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Yes, aluminum coils can be recycled multiple times without losing their properties. Aluminum is a highly recyclable material and can be melted down and reused indefinitely without any significant degradation in its properties. This makes aluminum coils a sustainable and environmentally friendly choice for various applications.

- Q: Can aluminum coils be used in heat exchangers?

- Indeed, heat exchangers can utilize aluminum coils. The utilization of aluminum in heat exchangers is prevalent owing to its exceptional thermal conductivity and resistance to corrosion. Aluminum's remarkable thermal conductivity enables efficient heat transfer, rendering it an optimal substance for heat exchangers. Furthermore, the coils' endurance and functionality in challenging surroundings are guaranteed by aluminum's resistance to corrosion.

- Q: What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, adhesive bonding, mechanical fastening, and soldering. Welding is a widely used joining technique for aluminum coils. Different welding methods, such as gas tungsten arc welding (GTAW or TIG), gas metal arc welding (GMAW or MIG), and laser welding, can be employed to fuse the aluminum coils together. Welding provides a strong and durable joint, ensuring structural integrity. Adhesive bonding is another technique used for joining aluminum coils. It involves the application of a suitable adhesive or bonding agent to join the coils together. Adhesive bonding offers excellent flexibility, as it can join dissimilar materials and create a smooth, aesthetically pleasing surface. Moreover, it distributes stress evenly across the joint, reducing the risk of fatigue failure. Mechanical fastening involves the use of mechanical elements like bolts, screws, rivets, or clips to join the aluminum coils together. This method is relatively simple and cost-effective, allowing for easy disassembly if needed. Mechanical fasteners provide good strength and stability but may require periodic maintenance to prevent loosening over time. Soldering is a technique that uses a low-temperature alloy to join aluminum coils. It involves heating the solder to its melting point and allowing it to flow into the joint, creating a strong bond. Soldering is commonly used for electrical connections or delicate applications where excessive heat can damage the aluminum. However, it may not provide the same strength as welding or mechanical fastening. The choice of joining technique for aluminum coils depends on various factors, including the specific application requirements, desired strength, appearance, and cost considerations.

- Q: What is the typical density of aluminum coils?

- The density of aluminum coils can differ depending on the particular alloy and manufacturing method employed. Generally, aluminum coils have a density of approximately 2.7 g/cm³. This value is slightly lower than pure aluminum, which has a density of 2.7-2.8 g/cm³. It should be noted that the density of aluminum coils can also be affected by factors such as coil thickness and any surface coatings or treatments applied.

Send your message to us

Mill Finished PE Coated Aluminum Sheet and Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords