Paintable Fiberglass Ceiling Tiles for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

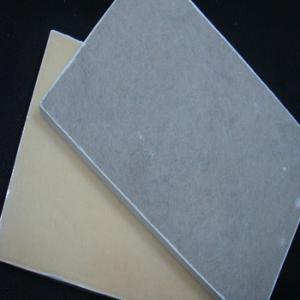

The surface of fiberglass ceiling with a pure and gentle pattern, produces a comfortable feeling of the interior decoration

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: I have a den that has 12inch acoustic ceiling tile that drips water sometimes when the weather is cool.I have checked and the attic above it is thoroughly insulated. The tile was installed on furring strips direct up against the fiberglass insulation,with no drywall in between the two, materials.The roof has ridge vents and the soffits,has perforated panels. There is also a 4 foot recessed fluorescent light in the center of the ceiling that looks like a week-end novice creation,that leaks cold air around it,a little. I have lived here for 10 years and have had this problem,the entire time. Two years I had the roof replaced thinking that it would solve my problem , because the ceiling was sprouting wet spots,randomly every where. What can I do about this madness?

- Moisture or condensation occurs when relatively warm-moist air comes in contact with a cold surface. You need to either eliminate the air leakage supplying the moist air, or do something (usually insulate) the surface to keep it's temperature warmer to prevent condensation or a combination of both.

- Q: Waterproof acceptance how to accept kitchen and toilet waterproof is done?

- Hope to help you get, feel good, please accept Thank you! Fireproof materials are mainly non-combustible materials and B1 grade flame retardant materials. Class A Noncombustible Material: Granite, marble, terrazzo, cement products, concrete products, gypsum board, lime products, clay products, glass, tiles, mosaic, steel, aluminum, copper alloy; B1 grade flame retardant material: Plastic materials, gypsum board, fiber gypsum board, cement particle board, mineral wool decorative sound absorption board, glass wool decorative sound absorption board, perlite decorative sound absorption board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative panels, Flame retardant wood, aluminum foil composite materials, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials; Wall material gypsum board, fiber gypsum board, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood, flame retardant medium density fiberboard, fire plastic decorative panels, flame retardant double-sided particleboard, colorful paint , Flame retardant wall paper, fire-resistant imitation granite decorative plate, magnesium chloride cement assembly wallboard, flame retardant glass steel plate, PVC plastic wall panels, light high-strength composite wall panels, flame-retardant molded wood composite sheet , Color flame retardant wood-based panels, flame retardant glass and steel

- Q: Due to circumstances too complicated to go into, my husband and I ended up trying to finish the drywall on our kitchen ceiling ourselves. We were in a bind and couldn't get a contractor, so we used compound, taped, sanded, primed and painted the ceiling 2 weeks ago. In some places the tape has bubbled, in others it's clearly visable under the tape, the ceiling looks, well, bad.My question is: how best to fix it? Do we sand down to the original tape (please, nononono!) and redo it? Is there a textured paint we could use? Pressed tin panels (country house)? We don't have a lot to spend on the project, so any advice would be appreciated! (Yes, I know we messed-up when we painted)

- When doing drywall you have to treat it as an art form. Much like putting icing on a cake. Also, it should have taken about 3 days for the joint compound to dry fully. My suggestion would be to reapply joint compound and be liberal with it where the tape is having problems. Next wait 2 days and then sand those areas. Then re apply more compound, a much thinner layer this time. Wait 2 days and sand again, lightly. Then paint. About the texturing.... you can get a brush from a home improvement place the is used for texturing ceilings with joint compound, just ask someone who works there. Then just dab joint compound on the ceiling.

- Q: How to choose table tennis floor

- Give you recommend the best floor ~ ~ butterfly king

- Q: We are rennovating my basement. There was a drop ceiling and thin paneling on the walls. I took out the drop ceiling and the paneling. The main goal is to get an efficient way to heat the space. The house has radiator heating so I figured we could use the heat from the pipes as the main heating source.We will put in a new drop ceiling that stays above the pipes (exposing the pipes will heat the space). What kind of insulation is recommended for the new drop ceiling to keep the heat in? I was recommended either fiberglass or foam insulation.The framing on the walls is good and I would like to reuse. What type of insulation on the walls? We will be drywalling them. Once again, I was recommended fiberglass but to put a plastic barrier between the wall and insulation. What do you think?I am open to any suggestions.Thanks!

- For the walls use fiberglass kraft faced(paper on one side) and no plastic or unfaced insulation with plastic. R-11 or R-13 for 2x4 walls. For the ceiling, I wouldn't bother with it. Instead add a radiator to the basement area and add a new pump and thermostat to create a new zone. Otherwise the basement would only be heated when some other area of the house needs more heat, this usually makes the basement too cold or too hot.

- Q: What is the solvent content of the insulation board?

- Extrusion board external wall insulation materials The system is the use of XPS polystyrene extruded board (hereinafter referred to as extruded board) as the building exterior insulation materials, when the main building and the external walls of masonry works, in the bottom mortar coated XPS special interface agent. The extruded polystyrene paste is coated with an adhesive mortar as required and is anchored with a plastic expansion screw. And then in the extruded plate surface coated with polymer cement mortar, which pressed into the alkali-resistant fiberglass mesh to strengthen the crack into the protective layer of mortar, and finally for the putty and paint the decorative layer (such as the decorative layer for the tile, You should switch to galvanized steel wire mesh and special tile adhesive and gluing agent). XPS extruded polystyrene board thin plaster external wall insulation system comparison EPS system, with higher strength, better insulation properties, less air permeability and other characteristics. The system is a relatively high-grade insulation isolation system in the cold areas, high-grade real estate, cold storage works and other high insulation requirements of the construction has been widely used.

- Q: What is the optical fiber made of material?

- The main ingredient in quartz stone made of silicon oxide! The

- Q: How to decorate the living room

- Color and light - the layout of color and lighting is the main means of reflecting the artistic aesthetic and personality of the master. Color, should be the overall tone to be unified, do not use too much color, or will make the whole space is very messy. Note that the color decoration with soft decoration, which will produce your unexpected effect. Daytime living room to natural light-based, as far as possible to the natural light into the room; evening to artificial lighting, including decorative chandelier lighting, ceiling lamps, embedded lights and walls, such as mixed lighting, but to ensure that the room is bright Is still the first choice of lamps and lanterns, and then through the light to increase the level of space, contrast atmosphere.

- Q: I have hanged the drywalls on both the ceiling and walls. My questions is how should I tape the joints between the ceiling and walls? Should I use a regular paper tape, a fiberglass mesh or a paper corner bead (inside corner)?

- On a full sheet, the factory edge is dished down for taping. When to factory edges are stacked together, or nailed one along the other, use mesh tape, this is a freebie. Fill it up with a 5-6 knife and wipe off excess with 9 or 12 . On the long side of a full sheet this edge is not tapered and is called the butt end. Two sheets nailed together is the butt ends. This is optional. Mesh is easier, paper tape is better. Corners take paper tape. Spread a coat of mud with either a flat knife to both sides or use a inside corner trowell that does both sides. Crease tape into 90 angle. Lightly slide into corner, hold with left hand, and strech an place lightly with the other. Take your corner trowell and run over paper tape lightly spreading out mud, and tape. If there are any blister areas, you didn't get enough mud on the wall. Lightly lift tape and mush some more mud under the tape. Resmooth out the mess the best you can. On corner bead, nail evenly from center up and center down with opposing nails. Cover these with a coat of mud with a 6 knife and pretend like you know what you're doing and have a little fun.The drywall god's wisdom is this. After the first coat has completely dried(overnight) do not sand. Take you knife and knock off high chuncks and spread another coat. After it has dried completely, knife again and put on your last coat. You should be looking good by now. Then you can lightly sand. Don't bother with a sponge if you want a truely good job, because they follow the contour of what's there. Lightly sand and it should come out puss.

- Q: Home improvement waterproofing process and what is the standard

- 1, waterproof construction should be used for waterproof coating materials. 2, waterproof material performance should be consistent with the provisions of the relevant national standards, and product certification should be a certificate. 3, the base surface should be flat, no hollowing, from the sand, cracking and other defects. Base water content should meet the construction requirements of waterproof materials. The waterproof layer should extend from the ground to the wall, 250mm above the ground. Bathroom wall waterproof layer height of not less than 1800mm. 4, waterproof cement mortar leveling layer and foundation with dense, no hollowing, the surface smooth and smooth, no cracks, from the sand, yin and yang angle made of circular arc. 5, coated with waterproof coating evenly, the thickness of the technical requirements to meet the requirements of the general thickness of not less than 1.5mm not exposed at the end. 6, the use of construction stubble should be along the direction of water lap, lap width of not less than 100mm, the use of two or more fiberglass cloth up and down lap when the width should be staggered one-half. 7, the coating surface is not blistering, no flow, smooth no bumps, and pipe fittings, sanitary ware to the ground, floor drain, drain seams tightly rounded without leakage. 8, the protective layer of cement mortar thickness, strength must meet the design requirements, the operation is strictly prohibited damage to the waterproof layer, according to the design requirements of the ground water slope, drainage should be smooth, no water back slope phenomenon. 9, waterproofing works after completion, must do 24 hours water storage test.

Send your message to us

Paintable Fiberglass Ceiling Tiles for Sound Absorption

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords