Outside Panel WPC Floor Laminate Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Outside Panel WPC Floor Laminate Flooring

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Outside Panel WPC Floor Laminate Flooring

WPC/PVC outdoor decking, indoor decking, soft pvc decking, wall panel, handrail, arbor,stand colum, tray panel, keel, grilling, connection, horny line, great wall panel, buckle ceiling, square pillar, door frame, door line, door mullion, PS foam profile, Accessoreis

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

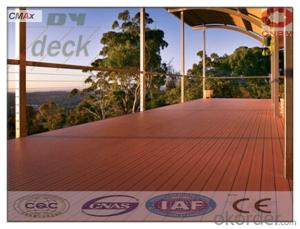

三.Outside Panel WPC Floor Laminate Flooring Images

四.Outside Panel WPC Floor Laminate Flooring Specification

Name | Outside Panel WPC Floor Laminate Flooring |

Size | W*H=145*30 mm, CUSTOMIZED |

Length | 2200mm, 2900mm, 5400mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Outside Panel WPC Floor Laminate Flooring

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: How to remove the plastic protective film on the floor angle

- There are three kinds of brick protective film:plastic filmBe able to gradually tear with the hand or be able to gently wipe with a steel ball.Antifouling protective filmThe protective film can be dipped in white cement with a towel.Ceramic tile protective filmBe able to scrub with a dry towel, scrub with an electric thinner or banana, and also use talcum powder and white cement.

- Q: How about the plastic floor?

- 4 comfortable, there are a variety of optional thickness, coefficient of resilience.5 price coverage.6 if you want to change, as long as the above and then paste a layer can be.

- Q: Who knows PVC plastic floor tiles?

- Ultra thinStone plastic floor tiles only 2 - 3mm thickness, the weight per square meter is only 2 - 3KG, less than the ordinary ground material of 10%. In the high-rise building for the building bearing and space saving, has an unparalleled advantage. At the same time, it has special advantages in the transformation of old buildings.

- Q: Now decorated with qVC plastic floor can do

- Can be used, PVC plastic floor is widely used such as

- Q: Plastic floor gap can be used to do plastic glass

- Buy plastic floor is a choice of material, how to install the plastic floor, plastic floor price, how much money the plastic floor, Shanghai plastic flooring, plastic flooring manufacturers, professional plastic floor, Fuzhou plastic floor, plastic floor thickness, plastic floor of environmental protection, Hangzhou plastic floor, size of plastic flooring, plastic flooring specifications, plastic floor how much money Nanjing Hefei Yiping, plastic floor, plastic floor

- Q: Spread a layer of plastic cloth under the wooden floor

- A plastic cloth can be laid under the wooden floor.Moistureproof layer, a layer of felt or plastic film, the ground will be able to cut off the water vapor condensed, and let it pass around the foot of a wall left side seam, emitted into the air. Moisture proof material integrity, damage or joints should be repeated cover. Now some of the lower ground floor of the house to do a half basement treatment, can also play a better role in moisture

- Q: Is it suitable for plastic floor? What's the harm?Is it suitable for plastic floor? What's the harm? Please specify. With price

- Since the plastic floor can go to the public life, it shows that it has its own unique advantages:1 elastic, comfortable, can give people a warm feeling;2 surface into the UV treatment, pollution resistance, easy to clean;

- Q: What is the material of the plastic foam plate

- The general use of four roller mill factory plasticized PVC, after the pressure of the surface is smooth and smooth, cooling after the edge of the strip is the product

- Q: Free glue self-adhesive stone PVC floor leather plastic floor glue floor toxic

- As long as the material is PVC plastic floor, basically are environmentally friendly, more plastic factory is mioT answer for you

- Q: PVC plastic floor can be used as a kitchen operating room, right?

- PVC floor. Can be used in the kitchen. The operation room in the hospital is also used in this roll floor.

Send your message to us

Outside Panel WPC Floor Laminate Flooring

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords