Residential Click Lvt PVC Vinyl Floor covering With Wood Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packing Detail: In carton/pallet as requested.

Delivery Time: 20 days after received 30% prepayment.

Application:

Vinyl flooring is widely used in office,super market,hospital,house,

bathroom,Kitchen and other commercial places.

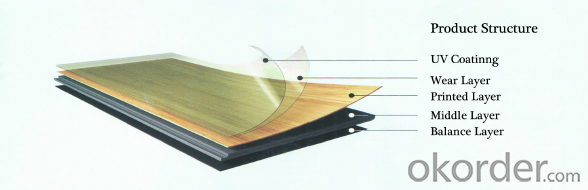

It is made of wear layer,pvc material and printed layer,which is a new type floor decoration material in the world.

Because environmental,cheap,easy to install,colorful and light than ceramic tile,

the vinyl foor is very popular.

Product Structure:

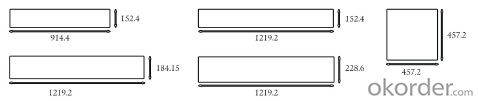

Size:

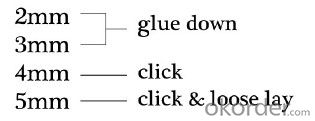

Thickness:

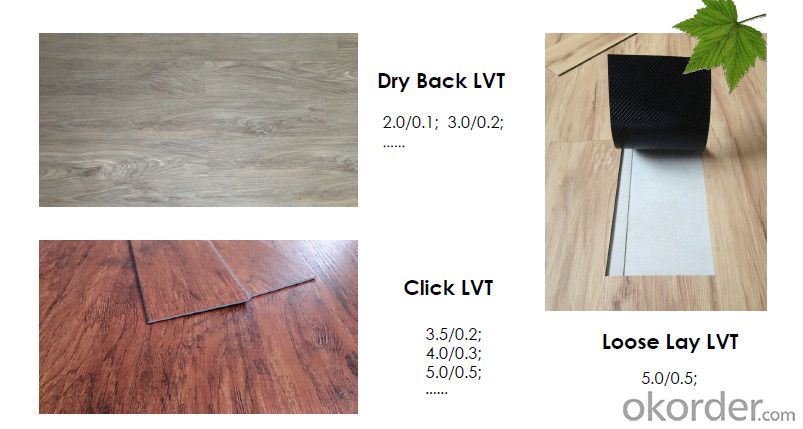

Specification:

Production:

- Q: What is the badminton sports floor?

- Badminton floor surface by special treatment, consistent with the brightness of the light, not absorb light and reflective glare, athletes can better protect the eyes, not easy to produce fatigue, the total thickness of 4.5mm, together with the appropriate foam bottom for the buffer layer, the shock absorption and rebound. To effectively alleviate the leg impact force, athlete's foot feeling comfortable, better avoid sports injury, improve the level of athletes to play.

- Q: What are the reasons for the price rise of PVC plastic floor

- Defects are thermally stable and shock resistant are poor, both hard and soft PVC easy to produce brittle during use. General PVC is not containing the relevant national standards allow the use of two (2 - ethylhexyl) adipate plasticizer (DEHA), DEHA in the high temperature (over 100 degrees Celsius) easily released, after contact with human health hazard.

- Q: The new rent a house, rough housing, house, do not want to decoration, but the cement really ugly, but the old feeling clean and fresh, a plastic carpet, feel the taste, said that before reading not made of plastic cloth, do not know whether to shop on the ground is also very harmful to me? Want to know now: plastic carpet and cement that is more harmful to human body?

- Plastic carpet is also known as rubber carpet, its scientific name is polyvinyl chloride resin, also known as PVC. The plastic carpet is the use of PVC material and plasticizer and other materials, through mixing plastic special a. Plastic carpet because of its main material is plastic, so there will be a lot of consumers worried about whether it will be toxic. In fact, this kind of worry is right and wrong. PVC material does not contain formaldehyde, so the plastic itself is not toxic, but in the process of manufacturing plastic need to add additives, if this kind of object will produce toxic gases. The production process and technology most well-known plastic carpet manufacturers with advanced environmental protection, can replace toxic additives, but some small brands or brand-name no technology, cost savings, on the use of inferior additives, lead to the release of formaldehyde. Therefore, the plastic carpet itself non-toxic, but some of the poor quality plastic carpet is toxic.

- Q: What is a plastic floor?

- The plastic floor is very popular in the world today a new light ground decoration materials, also known as the "light body material" in Europe and Asia, Japan and South Korea are popular, popular abroad, from the beginning of 80s to enter the China market, it has been widely accepted in the domestic large and medium-sized city

- Q: What a pig with plastic floor to sell, how much money

- Farmers - Sheng - Le plastic drain board it is unique1: the temperature difference between day and night plastic is smaller than iron, is conducive to the health of piglets and sows, so as to avoid temperature and cold or scald.2: the surface of the manure board matte treatment, increase the contact surface, improve friction, so as to prevent the fall of injured animals.3: washing machine can be used to wash the high-pressure water gun, made into a day without cracks, should not be hidden dirt.4: the company's production of plastic drain board made of pure raw materials, white shiny surface, high quality, durable.5: the plastic plate is suitable for conservation, piglets in farrowing crate bed, bed, sheep dog cage Quanshe dung floor

- Q: Plastic foam on the floor there is no effect of moisture

- The plastic film under the wooden floor is called the ground mat, which can be used to play the role of moisture. Prevent moisture and moisture, so as to avoid the floor because of water seepage to the wood floor deformation. If there is no ground floor and the floor will be rubbing friction sound. There is also can play a role in the formation of the ground. Is an indispensable procedure.

- Q: Have engaged in the PVC floor production or research work of predecessors, I am a college student in the existing fireproof problem research project called the PVC floor, check a lot of information without too much of the harvest hope that senior for guidance

- Fireproof material: a kind of synthetic material with fireproof characteristic matrix or material with high temperature resistance, heat resistance and flame retardance.Therefore, the fire retardant material has the characteristics of flame retardant.

- Q: Warm the house, with plastic floor?

- Warm the house, with plastic floor?Sky0384 | browse 928Posted on 2014-08-14 16:34 best answerNo problem with heating, the premise is to buy a good quality brand plastic floor. Such as the LG floor, my home for two years, I feel good, than the wooden floor, like when dealers, abrasion resistance, stain resistance, anti slip, sound insulation, heat conduction, fast walking, feel comfortable, beautiful color texture mosaic diversity without fracture, dimensional stability and construction of heat and moisture are not deformation, environmental protection I think all the advantages of formaldehyde free experience. There are five people in my family, there are elderly people have children, with the ground heating.

- Q: PVC plastic floor can be used as a kitchen operating room, right?

- Seems to be floor paint How do I know what it is?

- Q: What is the difference between plastic floor leather and plastic floor tile

- Floor leather is a kind of soft plastic floor general, only two layers of plastic, not wear-resisting layer, easy aging deformation, heavy pressure after formation of indentation can not be restored, and is not easy to electrostatic fire

Send your message to us

Residential Click Lvt PVC Vinyl Floor covering With Wood Designs

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords