Freezer Packaging Tape OPP Tape Film Blue Packaging SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Opp Tape Film Blue Packaging SGS&ISO9001

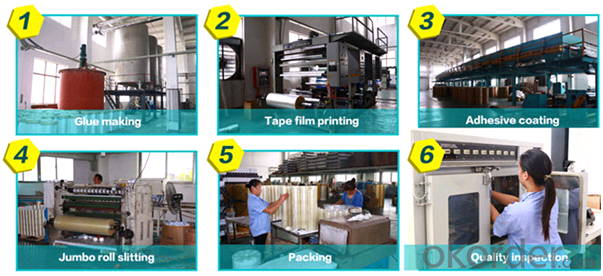

1. Structure of OPP Tape Description

BOPP tape is made from BOPP film with a layer of water based acrylic adhesive, low cost and wide use. It bonds instantly and adapts for most of the packaging area.

2. Main Features of the OPP Tape

Excellent in adhesion and flame retardant

Resistance to cold, heat and aging.

High Temperature stability

High mechanical strength

Ideal for use in dispensers

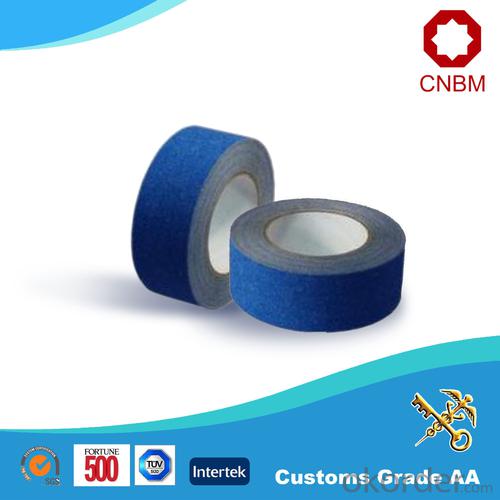

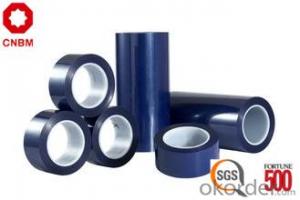

3. Bopp Tape Images

4. Bopp Tape Specification

Item No. | Thickness (micron) | Initial Tack (stell ball) | Adhesion to Steel (N/25mm) | Holding Power (hour) | Tensile Strength (N/625px) | Elongation at Break (%) |

BP-40 | 40 | >18# | 5 | >24 | >30 | <180 |

5. FAQ

Q1. What is the specification and packing for Bopp Tape?

Specifications:

1) Length: 3,000m, 4,000m, 6,000m

2) Width: 980,1020,1040,1255,1270,1280,1320,1600,1620mm

3) Thickness:35-70mic,depends on customers requests

Packaging: Bubble pack, then kraft wrap

Q2. What kind of service we can provide?

Professional consultation on your local market

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Satisfactory sales service

Q3. What is the Applications?

1) Used for packaging, bunding, wrapping, gift wrapping etc

2) Medium & Heavy Carton sealing, box sealing, bag sealing

3) Sealing all bags, steadying and bundling, protection, decoration

4) Excellent performer for both hand and machine application in factory, house supermarket etc.

- Q: Can packaging tape be used for sealing musical instruments or equipment?

- Musical instruments or equipment should not be sealed with packaging tape. Although packaging tape is intended for securely sealing boxes and packages, it is not appropriate for sealing musical instruments or equipment for a variety of reasons. Firstly, the use of packaging tape may result in residue or adhesive marks on the surface of the instrument or equipment, potentially causing damage to the finish or overall appearance. Musical instruments and equipment often possess delicate finishes that necessitate special care and attention, and the application of packaging tape could lead to unwanted marks or harm. Secondly, packaging tape may not provide adequate protection or support for fragile or valuable musical instruments or equipment. Musical instruments, particularly those crafted from wood, can be sensitive to fluctuations in temperature, humidity, and pressure. The utilization of packaging tape may not offer the requisite protection to prevent harm during transportation or storage. Instead, it is preferable to employ specialized instrument or equipment cases, covers, or bags that are specifically designed to provide proper protection and support. These cases are purposefully crafted to accommodate the shape, size, and fragility of musical instruments or equipment, ensuring their safety during transportation or storage. If you require sealing a case or cover for musical instruments or equipment, it is advisable to utilize suitable sealing methods as recommended by the manufacturer. This may involve zipper closures, Velcro straps, buckles, or other mechanisms specifically devised for securing musical instruments or equipment. In conclusion, although packaging tape can be valuable for sealing boxes and packages, it is not appropriate for sealing musical instruments or equipment. To guarantee the safety and protection of your musical instruments or equipment, it is best to employ specialized cases or covers designed for this purpose.

- Q: 2014, how can I sell the tape better?

- Second, your after-sales service can do what extent, can be exchanged or can not sell, you can return, this should be explained in detail, this is very important for customers,Third, your personal image, must give people a good impression, don't speak slow, simple, but not to sell the tape as the theme, you are going to help customers find a good product, because you give customers a profitable product, you do not help him, you just the customer is a friend, not God, to treat him as a friend, to be sincere,

- Q: Is packaging tape resistant to extreme pressure or weight?

- The purpose of packaging tape is to secure packages with a strong and reliable seal. However, the ability of the tape to withstand extreme pressure or weight can differ depending on its type and quality. Typically, packaging tapes are crafted from resilient materials such as polypropylene or polyester, enabling them to endure typical handling and transportation pressures. Nevertheless, it should be noted that packaging tape might not withstand excessively heavy loads or excessive pressure. In such instances, it is suggested to enhance the tape's strength by adding extra layers or employing heavy-duty tapes that are explicitly designed for high-pressure or weight-bearing purposes.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers. Packaging tape is designed to securely seal boxes and packages, and it provides a strong adhesive bond. When applied properly, it can effectively seal the openings of plastic pet carriers, ensuring that your pet is safely contained inside. However, it is important to ensure that the tape is applied evenly and securely to prevent any gaps or openings that your pet may be able to escape from. Additionally, it is recommended to check the tape periodically to make sure it remains intact and reapply if necessary.

- Q: Is packaging tape resistant to tearing or ripping?

- Yes, packaging tape is typically resistant to tearing or ripping. It is designed to provide a strong and secure seal on packages, ensuring that they remain intact during transit or handling. Packaging tape is made from durable materials such as polypropylene or reinforced paper, which offer high tensile strength and tear resistance. Additionally, many packaging tapes have adhesive properties that further enhance their resistance to tearing or ripping. However, it is important to note that the strength and tear resistance of packaging tape may vary depending on the specific brand or type of tape used.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- There are several advantages to using pre-printed packaging tape with warning messages. To begin with, it increases safety by clearly informing handlers of potential package hazards. These warning messages can include instructions like "Fragile," "Handle with Care," or "Do Not Stack," which prevent mishandling and reduce the risk of damage during shipping or transportation. By providing this crucial information upfront, pre-printed packaging tape ensures that fragile or sensitive items are handled properly, decreasing the likelihood of breakage, leakage, or other accidents. Additionally, it saves time and effort because the warning messages are already printed on the tape. This eliminates the need to separately apply warning labels or write instructions on the package, streamlining the packaging process. It also reduces the chances of labeling errors or inconsistencies since the pre-printed tape ensures a standardized and professional appearance. Moreover, using pre-printed packaging tape with warning messages enhances brand image and customer satisfaction. It demonstrates a dedication to quality and safety, which positively influences customer perception. It also helps establish trust and confidence in the company's products or services since customers can see that proper precautions are being taken to ensure the secure delivery of their items. Lastly, pre-printed packaging tape with warning messages can serve as a marketing tool. By incorporating the company logo, contact information, or promotional messages on the tape, businesses can effectively promote their brand and leave a lasting impression on customers. This increased visibility can boost brand recognition and potentially attract new customers. In conclusion, using pre-printed packaging tape with warning messages offers numerous benefits, including improved safety, time and effort savings, enhanced brand image, and marketing opportunities. It is a practical and efficient solution for businesses seeking to guarantee the secure and efficient transportation of their products.

- Q: Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags.

- Q: How do I seal a package securely with packaging tape?

- To seal a package securely with packaging tape, follow these steps: 1. Start by ensuring that the items inside the package are properly arranged and secured. 2. Cut a piece of packaging tape slightly longer than the width of the box. 3. Place the tape across the center of the box, ensuring it covers the flaps and overlaps on both sides. 4. Firmly press down on the tape to ensure it adheres properly to the surface. 5. Repeat this process with additional strips of tape, placing them parallel to the first strip and overlapping them slightly. 6. For added security, place strips of tape diagonally across the top and bottom flaps, creating an "X" pattern. 7. Apply pressure to the entire length of each strip to ensure a strong bond with the surface. 8. Finally, test the seal by gently tugging at the tape to ensure it holds firmly. By following these steps, you can seal your package securely with packaging tape, minimizing the risk of damage during transit.

- Q: What is the profit margin of the transparent tape for packaging?

- Now, many of the tapes are closed and the profits are too transparent

- Q: Does packaging tape have a specific shelf life?

- Indeed, there is a designated lifespan for packaging tape. The duration of this lifespan fluctuates depending on the type and caliber of the tape. In general, the majority of packaging tapes possess a shelf life spanning from one to two years. Nevertheless, this lifespan can be elongated or abbreviated due to certain factors such as storage circumstances and exposure to sunlight or extreme temperatures. It is crucial to consult the manufacturer's guidelines or packaging for any explicit instructions regarding the tape's shelf life. To guarantee optimal performance and adhesive potency, it is advisable to employ packaging tape within its designated shelf life.

Send your message to us

Freezer Packaging Tape OPP Tape Film Blue Packaging SGS & ISO9001

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords