Custom Printed Vinyl Packaging Tape - BOPP Tape 60 Micron Red Colour SGS & ISO9001 Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

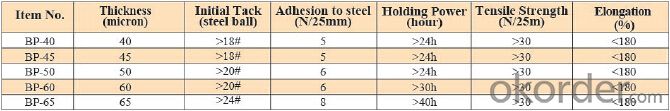

Typical Physical Reports of Masking Tape

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

Packaging & Delivery

Packaging Detail:

Log Roll: Width1280mm; length according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Bopp Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

About us

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Welcome to contact us and visit the factory!

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Acrylic and hot melt adhesives are two common types of adhesives used for packaging tape, and they have some key differences. One major difference is the bonding strength. Hot melt adhesive is known for its excellent bonding strength, making it suitable for heavy-duty applications. It creates a strong and durable bond that can withstand rough handling and varying temperatures. On the other hand, acrylic adhesive typically offers a lower bonding strength compared to hot melt adhesive. While it is still suitable for most general packaging needs, it may not be as ideal for heavy or bulky items. Another difference lies in the application process. Hot melt adhesive is applied in a molten state and solidifies upon cooling. It is typically dispensed using a hot melt glue gun or a hot melt applicator. The quick setting time of hot melt adhesive allows for fast packaging operations, making it popular in high-volume settings. In contrast, acrylic adhesive is applied in a liquid form and requires some time to cure and form a strong bond. It can be applied using a hand dispenser or a tape gun, and it usually requires some pressure for optimal adhesion. Additionally, hot melt adhesive offers good adhesion to a wide range of surfaces, including cardboard, plastics, and metals. It is highly versatile and can be used for various packaging materials. Acrylic adhesive also adheres well to different surfaces, but it may not have the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is another factor to consider. Hot melt adhesive performs well in both high and low temperatures, maintaining its bonding strength. It can withstand freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In summary, the main differences between acrylic and hot melt adhesives for packaging tape lie in bonding strength, application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, fast setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on the specific packaging needs, materials, and environmental conditions.

- Q: What are the considerations for using packaging tape on delicate surfaces?

- When using packaging tape on delicate surfaces, there are several considerations to keep in mind. Firstly, it is important to choose the right type of tape. Opt for a tape specifically designed for delicate surfaces, such as low-tack or painter's tape. These tapes are typically less sticky and have a gentler adhesive that won't damage or leave residue on sensitive materials like paper, fabric, or painted surfaces. Secondly, before applying the tape, ensure that the surface is clean and free from any dust, dirt, or moisture. This will prevent any particles or contaminants from getting trapped under the tape and potentially causing damage. When applying the tape, be cautious and gentle. Avoid pressing down too hard or stretching the tape excessively, as this can increase the risk of tearing or damaging the delicate surface. Take your time and carefully smooth out any wrinkles or air bubbles to ensure proper adhesion. Additionally, it is advisable to test the tape on a small, inconspicuous area of the delicate surface before fully committing to using it. This will help you assess its compatibility and whether it causes any adverse effects or damage. Lastly, when removing the tape, do so slowly and carefully. Pull the tape back at a low angle, parallel to the surface, to minimize the risk of tearing or leaving any residue behind. If any residue does remain, use a gentle adhesive remover or warm soapy water to clean the surface. By considering these factors, you can effectively use packaging tape on delicate surfaces without causing any harm or leaving unwanted marks or residue.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for sealing packages with jewelry or valuables?

- Yes, packaging tape can be used for sealing packages containing jewelry or valuables. It provides a secure and reliable seal, ensuring that the contents of the package are protected during transit.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: Are there different colors of packaging tape?

- In the market, one can find various colors of packaging tape. Although clear is the most commonly used color, there are also options like brown, white, black, and even vibrant choices such as red, blue, green, and yellow. The multiple colors of packaging tape serve different purposes. For instance, brown tape is frequently employed for sealing boxes and packages, white tape is commonly used for labeling or writing on, and colored tapes can be utilized for color-coding or enhancing the appearance of packages. The presence of diverse colors enables individuals and businesses to select the tape that best suits their specific requirements.

- Q: What are the considerations for using packaging tape on wooden surfaces?

- There are several factors to consider when using packaging tape on wooden surfaces. Firstly, it is crucial to select the appropriate type of tape for the wood. Choose a tape specifically designed for wood or one with a gentle adhesive to prevent damage or residue. Avoid strong adhesive or duct tapes that may leave sticky residue or peel off the wood's finish. Secondly, take into account the condition of the wood. If it is old, fragile, or has cracks, extra precautions are necessary. Applying tape directly to damaged or delicate wood can cause further harm, such as stripping the varnish or causing splintering. In such cases, alternative methods should be used to secure or protect the wood. Consider the duration for which the tape will be applied. If it is temporary, most types of packaging tape are generally safe to use. However, if the tape will be left on the wood for an extended period, choose a tape that is less likely to damage or leave residue when removed. Additionally, be mindful of the climate or environment in which the wood will be situated. Extreme temperatures or humidity can affect the adhesive properties of the tape, potentially causing it to lose stickiness or damage the wood. In such cases, alternative methods may be required to secure or protect the wood. Lastly, always test a small, inconspicuous area of the wood with the tape before applying it extensively. This allows for assessment of any potential damage or residue and helps make an informed decision about using the tape on the entire wood surface. By considering these factors, one can ensure the safe use of packaging tape on wooden surfaces without causing unnecessary damage or issues.

- Q: Can packaging tape be used for packing fragile items?

- Yes, packaging tape can be used for packing fragile items. It provides a secure seal and helps to protect delicate objects during transportation or storage. However, it is recommended to use additional protective materials, such as bubble wrap or foam, to further cushion and safeguard fragile items.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

Send your message to us

Custom Printed Vinyl Packaging Tape - BOPP Tape 60 Micron Red Colour SGS & ISO9001 Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 600 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches