Non-Woven Geotextile Drainage Fabric - Needle Punched Staple Fibers Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Staple fibers needle punched non woven geotextile

Introduction:

Staple fibers needle punched non woven geotextile is made of PP or PET staple fibers on carding cross- laying equipment and needle punched equipment.

Features: It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

Application: Mainly applied in water conservancy, road and railway for strengthening, separation, reversed filter and drainage of projects

Specification:100g~800g

Width:2m~6m

Properties of Staple fibers needle punched non woven geotextile

Item (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Note |

Mass error in unit area (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness (mm) ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Error of width (%) | -0.5 | |||||||||||

Breaking strength (KN/m)≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD/CD |

Elongation at break | 25~100% | |||||||||||

CBR puncture resistance (KN)≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Equivalent Pore size O90( O95) | 0.07~0.2 mm | |||||||||||

Vertical permeability coefficient | K×(10-4~10-3)cm/s | K=1.0-9.9 | ||||||||||

Tearing strength (KN)≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

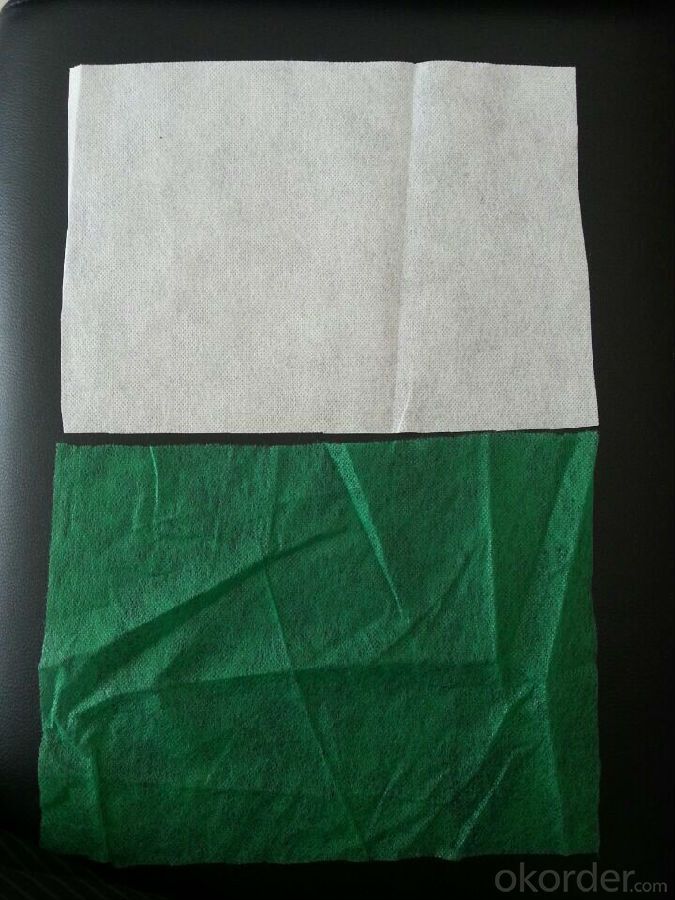

Images of non woven geotextile

- Q: Can geotextiles be used in groundwater control?

- Yes, geotextiles can be used in groundwater control. They are commonly employed as part of drainage systems to filter and separate different layers of soil, preventing the clogging and migration of fine particles. Geotextiles can also be used in conjunction with geosynthetics to create impermeable barriers, preventing the seepage or flow of groundwater in certain applications.

- Q: Geotextile water filter?

- Geotextile is used to filter the water, mainly to see where to use, and then consider the thickness of the cloth.

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stabilization. They act as a barrier that prevents soil particles from being washed away by water or eroded by wind. This helps in maintaining the integrity and compactness of the soil, leading to improved consolidation and increased load-bearing capacity. Additionally, geotextiles can also distribute the applied load more evenly, reducing differential settlement and promoting a more uniform consolidation process.

- Q: What are the advantages of using geotextiles in stormwater management?

- Geotextiles offer several advantages in stormwater management, including improved filtration and sediment retention, increased soil stabilization, and enhanced water infiltration rates. They help to reduce erosion and prevent sediment from entering water bodies, thus improving water quality. Geotextiles also provide support to vegetation and promote vegetative growth, contributing to the overall sustainability and effectiveness of stormwater management systems.

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: Can geotextiles be used in the protection of shoreline structures?

- Yes, geotextiles can be used in the protection of shoreline structures. Geotextiles are permeable fabrics that can be placed to prevent erosion and stabilize the shoreline. They can be used as a barrier between the soil and water to prevent soil loss and maintain the integrity of shoreline structures.

- Q: How do geotextiles help with soil erosion control?

- Geotextiles help with soil erosion control by acting as a barrier between the soil and water, preventing the loss of soil particles. They also improve soil stability by increasing its strength and reducing the impact of erosive forces such as wind or water flow.

- Q: How do geotextiles help with erosion control on shorelines?

- Geotextiles help with erosion control on shorelines by providing a physical barrier that prevents soil erosion, while allowing water to pass through. They stabilize the soil, reduce wave energy, and trap sediments, effectively protecting the shoreline from erosion caused by currents and waves.

- Q: What is the meaning of geotextile anchoring?

- Geotextile anchorage: is the geotextile in the construction of civil engineering construction in the slope of the fixed, to prevent the geotextile movement.

- Q: What are the factors to consider when selecting geotextiles for a specific project?

- When selecting geotextiles for a specific project, there are several factors that need to be considered. These include the type of soil and its properties, the intended purpose of the geotextile, the required strength and durability, the environmental conditions, and the installation and maintenance requirements of the project. Additionally, factors such as cost, availability, and the reputation of the manufacturer should also be taken into account.

Send your message to us

Non-Woven Geotextile Drainage Fabric - Needle Punched Staple Fibers Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords