No-Mar Mill Finished Direct Casting Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Direct Casting Aluminium Coil

Mill Finished Direct Casting Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Direct Casting Aluminium Coil

Mill Finished Direct Casting Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Direct Casting Aluminium Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Direct Casting Aluminium Coil

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Direct Casting Aluminium Coil

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

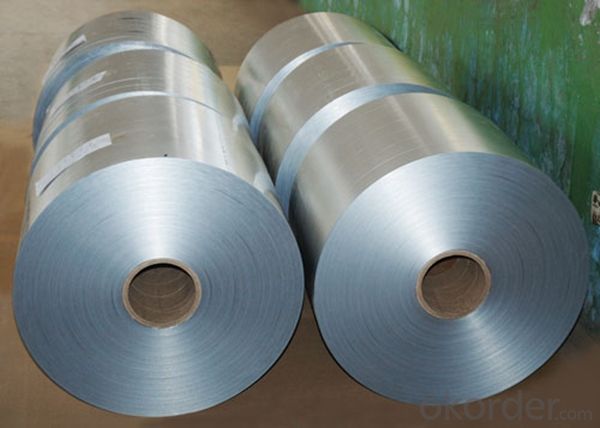

6. Image of Mill Finished Direct Casting Aluminium Coil

7. Package and shipping of Mill Finished Direct Casting Aluminium Coil

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in solar panel installations?

- Yes, aluminum coils can be used in solar panel installations. Aluminum is a popular choice for the construction of solar panels due to its lightweight nature, corrosion resistance, and excellent thermal conductivity. Aluminum coils are often used as the backing material for solar panels, providing structural support and heat dissipation. They are also commonly used in the manufacturing of solar mounting systems, which hold the panels securely in place. Overall, aluminum coils are a reliable and efficient option for solar panel installations.

- Q: Is it possible to use a crowbar as a tool for opening an aluminum coil?

- <p>While a crowbar can be used to apply force to open various objects, it may not be the most suitable tool for opening an aluminum coil. Aluminum coils can be sharp and using a crowbar could lead to injury or damage to the coil. It's recommended to use gloves and a pair of pliers or a coil cutter specifically designed for handling aluminum coils to ensure safety and avoid damaging the material.</p>

- Q: Can aluminum coils be used in explosive environments?

- No, aluminum coils should not be used in explosive environments. Aluminum is a highly flammable metal, and when exposed to certain conditions, it can ignite and contribute to the spread and intensity of a fire. In explosive environments, such as those containing gases, vapors, or dust particles, the risk of fire or explosion is already heightened. Therefore, it is essential to avoid using aluminum coils in such environments to prevent potential ignition sources and ensure the safety of the surroundings. Instead, materials with higher resistance to heat and fire should be utilized in these hazardous settings.

- Q: What is the density of aluminum coils?

- The size, shape, and composition of aluminum coils can cause variations in their density. On average, aluminum has a density of approximately 2.7 grams per cubic centimeter (g/cm³). This implies that each cubic centimeter of aluminum coil weighs around 2.7 grams. It should be emphasized that the density may slightly differ due to impurities or alloying elements, but the average value serves as a reliable estimate for the density of aluminum coils.

- Q: Aluminium forms layer of aluminium oxide when exposed to air. This prevents further reaction.However, isn't aluminium oxide an amphoteric oxide that can react with both acids and alkalis?

- Like hell, it can.

- Q: Are aluminum coils resistant to corrosion?

- Indeed, corrosion is something that aluminum coils can withstand. The reason behind this lies in the presence of a natural oxide layer on the surface of aluminum, serving as a safeguard against corrosion. When aluminum comes into contact with oxygen in the atmosphere, this oxide layer is formed. Consequently, direct interaction between the metal and moisture or other corrosive elements is prevented. Furthermore, aluminum coils can undergo additional protective measures like anodizing or painting. These measures offer an added shield against corrosion, thereby enhancing the durability of aluminum coils, making them exceptionally resistant to rust and other types of decay.

- Q: This question asks about the maintenance difficulty of aluminum coils.

- <p>Aluminum coils are relatively easy to maintain. They are resistant to corrosion and do not require frequent cleaning or special treatments. Regular inspection for any physical damage or signs of wear is sufficient. However, it's important to keep them dry and clean to prevent any potential issues. For specific applications, such as in HVAC systems, regular cleaning may be necessary to ensure optimal performance. Overall, maintenance is minimal compared to other materials.</p>

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

- Q: Are aluminum coils suitable for insulation purposes?

- No, aluminum coils are not suitable for insulation purposes.

- Q: What are the different finishes available for aluminum coils?

- There are several different finishes available for aluminum coils, including mill finish, anodized finish, painted finish, and embossed finish. Mill finish is the standard finish and has a smooth, shiny appearance. Anodized finish involves an electrolytic process that adds a protective layer to the aluminum, providing increased durability and resistance to corrosion. Painted finish involves applying a coating of paint to the aluminum, offering a wide range of color options and enhanced aesthetics. Lastly, embossed finish involves creating patterns or textures on the aluminum surface, adding visual interest and improving grip.

Send your message to us

No-Mar Mill Finished Direct Casting Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords