China Diamond Embossed Aluminum Coil for Aluminum Sheet & Strip Producing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Coil Used for Aluminium Sheet & Strip Producing

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Aluminium Coil Used for Aluminium Sheet & Strip Producing

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Coil Used for Aluminium Sheet & Strip Producing

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

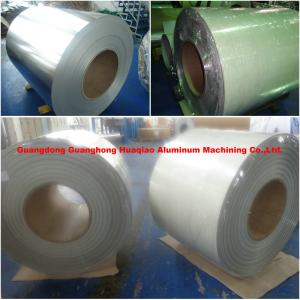

5. Image of Aluminium Coil Used for Aluminium Sheet & Strip Producing

6. Package and shipping of Aluminium Coil Used for Aluminium Sheet & Strip Producing

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the cost-effectiveness of using aluminum coils in the long run?

- The cost-effectiveness of using aluminum coils in the long run is high. Aluminum coils are durable, corrosion-resistant, and have a long lifespan, reducing maintenance and replacement costs over time. Additionally, aluminum is a lightweight material, resulting in energy savings during transportation and installation. Moreover, aluminum coils offer excellent thermal conductivity, enhancing energy efficiency in heating and cooling systems. Overall, while the initial investment may be higher, the long-term benefits of using aluminum coils outweigh the costs.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q: Can aluminum coils be used in the production of electrical cables?

- Yes, aluminum coils can be used in the production of electrical cables. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity and lightweight properties. Aluminum coils are commonly used to manufacture power cables, building wires, and other electrical conductors. They have been proven to be a cost-effective alternative to copper coils, which are more expensive but possess higher electrical conductivity. The use of aluminum coils in electrical cables can help reduce the overall weight of the cables, making them easier to install and handle. Additionally, aluminum coils have good corrosion resistance, making them suitable for outdoor and underground applications. However, it is important to note that aluminum has a lower tensile strength compared to copper, so proper design considerations and installation techniques must be taken into account to ensure the longevity and reliability of aluminum-based electrical cables.

- Q: I have been trying to make some thermite for a while now, and I haven't had much success. I have tried using iron oxide and that didn't work. then I tried using manganese dioxide, also without success. I'm pretty sure I have the right proportions for each of the corresponding oxides, but it just isn't working. I am using magnesium ribbon to light it.The aluminum I am using is the byproduct of me trying to cut a block of aluminum with a hacksaw (best way I have available to cut it) and there is a lot of aluminum powder that is being made. But i'm not sure if it is fine enough to be effective. I don't have an etch-a -sketch so that's not an option. I know that it has to be fairly fine grained, but how small do the particles need to be?FOR EVERYONE WHO IS GOING TO TRY AND TELL ME THAT MAKING THERMITE IS DANGEROUS OR SOMETHING ALONG THOSE LINES......DONT!!!!!!!!.......... IM NOT GOING TO LISTEN SO SAVE YOURSELF THE TYPING AND ME THE READING

- In 35+ years of demonstrating the thermite reaction, I have used fine aluminium powder to quite visible small bits. The proportions don't seem too critical, but try and keep near the amounts represented by the balanced eqtn. The difficult bit is getting the wretched stuff to ignite. With some mixes several strands of magnesium ribbon as fuse still wouldn't get it to ignite. I found a pile of 'ignition powder' at the base of the Mg often helped. There was a good commercial one available in the UK but I often made one up, main ingredients barium peroxide and magnesium powder, about 50/50. Needless to say, ignite with this mix where you won't breathe any nasty fumes. To get a good result, if I didn't use a proper crucible, I shaped one of Al foil about the capacity of 2-3 eggcups. This was put on sand in a big coffee tin, then more sand added to fill round the sides. This would give a good amount of iron. I once made the mistake of rushing in too quickly to get out the red hot iron.... and completely melted the ends of a large pair of Nickel tongs!

- Q: A magnet will not attract a aluminum bar, but if you have an electromagnetic field made by an transformer it will interact.Why is that?Why iron is attracted and wood is not?

- Aluminum is not a magnetic material and will not be affected by stationary magnets. However, if a changing magnetic field is present, an electrical voltage will be induced in the aluminum ring and an electric current will flow as a result. This current will produce a magnetic field which will interact with the externally produced magnetic field. The key here is a changing magnetic field - because the voltage induced in the aluminum ring will be proportional to the rate of change of the field. If an aluminum disk is passed between the poles of a powerful magnet, eddy currents will be induced in the aluminum producing a magnetic field that will tend to retard the motion of the aluminum relative to the magnet. The changing field in this case is due to the motion of the aluminum. Iron is attracted to a magnetic field because it is a ferro-magnetic material. Wood is not a magnetic material, and it is not an electrical conductor, so it will not behave as aluminum does in a magnetic field.

- Q: Can aluminum coils be used for electrical conductivity purposes?

- Using aluminum coils for electrical conductivity purposes is not possible. Although aluminum is a decent conductor of electricity, it is not appropriate for coils that are specifically intended for electrical conductivity. Aluminum has a higher resistance in comparison to materials like copper or silver, which are frequently used for electrical conductivity purposes. Furthermore, aluminum has a lower melting point than copper, therefore utilizing it in coils for high electrical currents can result in overheating problems. Consequently, it is more typical to use materials such as copper or silver for electrical conductivity purposes, particularly in situations where high conductivity and low resistance are necessary.

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: I did a activity series lab and on my data table, it shows that lead reacted more than aluminum did, but aluminum is more active than lead. So, why does it show that lead is more active when it really isn't? Is it human error?

- Aluminum is more active than lead. You should double check your activity data table. If you confirm that the table says that lead is more active than aluminum, the table is in error.

- Q: Can aluminum coils be used in the production of aluminum cladding?

- Yes, aluminum coils can be used in the production of aluminum cladding.

- Q: How are aluminum coils used in the electrical industry?

- Aluminum coils are widely used in the electrical industry for various applications such as transformers, motors, generators, and electrical transmission systems. These coils are used to create electromagnetic fields, which are essential for the functioning of these electrical devices. Additionally, aluminum coils are preferred due to their lightweight, high thermal conductivity, and cost-effectiveness compared to other materials.

Send your message to us

China Diamond Embossed Aluminum Coil for Aluminum Sheet & Strip Producing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords