Ni-P Alloy Grooved Drum for Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

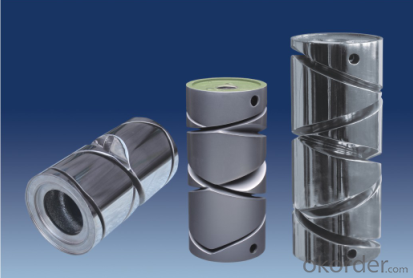

Structure of Ni-P Alloy Grooved Drum for Automatic Winder:

1. Best groove curve, ultra-fine processing, mirror polished surface, and high smooth finish(Ra<0.2μm).

2. We plating Ni-P on the surface;coating has high density,small crystallization , low porosity.Drum groove has complete coverage of coating, and the coating has good uniformity, excellent corrosion resistance.

3. Ni - P alloy coating is dealing with aging hardening and high temperature heat treatment. The hardness of the surface of Ni-P grooved drum can reach HV1100; it has the advantages of high wear resistance, high toughness, and low internal stress.

4. Higher wear resistance, higher corrosion resistance, higher uniformity, and longer life cycle.

Main Features of the Ni-P Alloy Grooved Drum for Automatic Winder:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

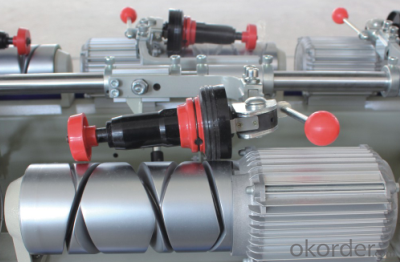

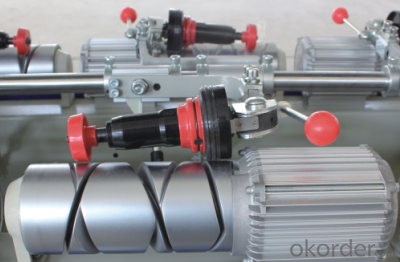

Images of Ni-P Alloy Grooved Drum for Automatic Winder:

Models of Ni-P Alloy Grooved Drum:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Packaging & Delivery of Ni-P Alloy Grooved Drum:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Yarn Winding Machine:

1. Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

2. Q: What is the MOQ?

A: 100 pc.

?3. Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- 2008-2010, with the rapid development of the world and China's textile industry, the demand for textile machinery more and more, China's textile industry development is facing a good opportunity. It is expected that by 2010, by the promotion of textile machinery, China's textile machinery industry, the new product output value will be increased from 25% in 2005 to 50%

- Q: What is the current status of the textile industry?

- The global textile industry market uncertainty is increasing, which with the global credit crisis and the United States, the EU economic growth slowdown in the trend will bring impact on the clothing retail industry. The dollar outreach, crude oil prices ups and downs and China's textile exports to Europe will lift the limit, are declared a major change. By the US economic slowdown, corporate sales will decline. And because the United States, Europe may implement new trade barriers, so the global textile industry procurement may be a significant change in the trend. In addition, there are less than 3 months, for the textile and apparel products quota system will end. This international textile and apparel trade system changes are the latest challenges faced by textile and garment enterprises, not only with hope and opportunity, but also with a great risk.

- Q: What are the main producing areas of Chinese textile machinery?

- While the southern Jiangsu and Zhejiang, mainly textile mills more, but there are many textile machinery manufacturers

- Q: Who invented Jenny spinning machine?

- In the mid-18th century, British goods were increasingly sold overseas, and the production of handmade workshops was inadequate. In order to increase production, people find ways to improve production technology. In the cotton textile sector, people first invented a shuttle called the weaving tool, greatly accelerated the speed of the weaving, but also to stimulate the demand for cotton yarn. In the 1860s, the weaver Hagreaves invented the "jenny machine" hand spinning machine. "Jenny machine" can be spinning a lot of cotton thread, greatly improving the productivity.

- Q: What is the cashmere dyeing process?

- Cashmere raw material prices affected by the larger market, in the same period, the general quality of the quality of washing cashmere determine its price. The finer the fineness of the fiber, the longer the length, the higher the amount of cashmere, the higher the price. Quality is closer, the highest price of white cashmere, followed by velvet, purple suede the lowest price. The principle of selection of raw materials is to meet the requirements of spinning under the premise of the lower the price the better. therefore...

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- Because the first "Jenny machine" is the machine, the first to complete the transition from tool to machine, on the other hand, due to the "Jenny machine" appears, it promotes the related weaving, power, transportation and a series of industry inventions and use Machine, which opened the prelude to the British industrial revolution. That is, our history books agree with the beginning of the industrial revolution signs!

- Q: What are the classification of textile machinery?

- 5. Modern textile machinery:

- Q: Textile machinery production process is probably what kind of?

- Carding parts of a wide variety of materials, many shapes, but generally is the first processing parts, according to the requirements of the drawings, in addition to the requirements of the part of the preparations are nothing more than casting and forging, welding pliers and so on.

- Q: What is the structure and working principle of Jenny's spinning machine?

- Spinning a hand when a small section of cotton yarn hook on the hook on the spindle, and then pull a sliver and cotton yarn caught, twisted in the hands. So that this piece of cotton bar was hooked with the handle fixed. This is called on both sides of the spinning grip, hand cranks on the small wheel to drive the spindle on the rotation called twisting.

- Q: China's textile industry prospects of printing and dyeing ?

- Prospective Industry Research Institute Textile Machinery Manufacturing Industry Research Group, said the world's leading textile machinery enterprises in China have invested and set up factories in China, the scale of production in China has reached the Chinese textile machinery production 1/3.

Send your message to us

Ni-P Alloy Grooved Drum for Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords