Ni-P Alloy Grooved Drum of Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

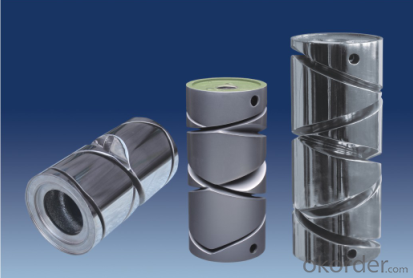

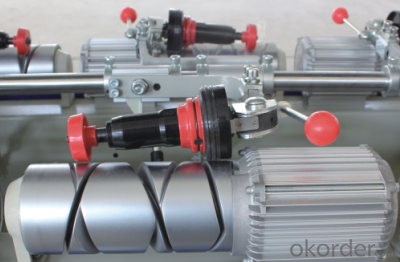

Structure of Ni-P Alloy Grooved Drum for Automatic Winder:

1. Raw material of Ni-P Alloy Grooved Drum for Automatic Winder: metal, Ni-P coated.

2. Product color of Ni-P Alloy Grooved Drum for Automatic Winder: shiny white.

3. Usage of Ni-P Alloy Grooved Drum for Automatic Winder: applied in groove drum type yarn cone winding machine.

Main Features of the Ni-P Alloy Grooved Drum for Automatic Winder

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Images of Ni-P Alloy Grooved Drum for Automatic Winder:

Specification of Ni-P Alloy Grooved Drum:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Packaging & Delivery of Ni-P Alloy Grooved Drum:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: The state of the textile industry machinery revitalization, expanding domestic demand, the specific policy is what?

- State textile machinery industry after decades of development, has made great progress. But compared with the world's advanced technology, there are still some gaps and some more serious problems. The overall technical level of textile machinery is low, product independent development and innovation ability is weak, lack of research and development funds. Enterprise technical reform is not enough, manufacturing technology behind

- Q: What are the general fixed assets of the textile industry?

- Vinylon filament spinning machine, cutting spinning roving machine, traction machine, drafting machine cutting machine

- Q: When did Chinese ancient textile technology come from? Why does Europe call China "silk country"?

- The world's first degumming linen - Gaocheng Taixi Shang Dynasty ruins of linen fragments, is currently found in the world's first artificial degumming linen. The expert identification, hemp yarn in the gum content is very small

- Q: What is the current domestic textile enterprises?

- Shandong Weiqiao Venture Group Co., Ltd., Nanshan Group Co., Ltd., Jiangsu Sunshine Group Co., Ltd.

- Q: What are the main producing areas of Chinese textile machinery?

- China's textile machinery industry base is located in Jiaonan City, Shandong Province, Wang Taizhen and Shanxi Province, Jinzhong City (Yuci District), the following is the town of Jiaonan City, Shandong Province, Wang Taizhen textile machinery industry status and Shanxi Province Jinzhong City (Yuci District) Introduction of Textile Machinery Industry.

- Q: Textile equipment to protect the work is not a special type of work?

- Second, the former Ministry of Textile Industry "on the trial" textile industry chemical fiber toxic and hazardous operations early retirement range "notice [(88) spinning word No. 19) document, the viscose fiber 33 jobs (carbon disulfide manufacturing Workers, calcium sulphate liquid preparation workers, diggers, detergents, bleach, sulfonation, plate and frame filter workers, spinning workers, filament twist and drop silk workers, filament head workers, filament silk Workers, cellophane workers, iron chrome salt manufacturing workers, cotton linen preparation workers, bleach workers, carbon disulfide library workers, carbon disulfide safety workers, short fiber post-processing workers, carbon disulfide recycling workers, precision workers and spinneret finishing workers , Outside the precision workmanship, the strength of wire accessories replacement workers, waste silk cleaners, strong wire tube finishing workers, strong wire metering pump complete work, strong wire grading workers and loading and unloading silk workers, strong wire packer, strong wire early twist Block machine, strong silk weaving workers, strong silk with plastic workers, sulfonation machine and spinning machine to protect workers, acid station acid bath workers, acid station security workers) as toxic and hazardous special types of work and the four types of work (not Including mechanical operators Of the unloading of carpenters, log porter, turning carpentry, split woodworking) as a particularly heavy manual labor special work

- Q: What are the risks of safety accidents in the textile machinery industry?

- There are all risks of security, one, the machine is faulty, do not attach importance to continue to use

- Q: Who invented Jenny spinning machine?

- Things start from the day of 1764. England Lancashire has a textile worker James Hargreaves, that night he went home, opened the door after accidentally kicked his wife is using the spinning machine, when his first reaction is to hurry Spinning machine righting. But when he bent down, but suddenly shocked, and he saw that the spinning was spinning the spinning machine is still turning, but the original sideways of the yarn now become upright.

- Q: What are the related fields of textile engineering?

- Business training objectives: The professional training with textile engineering knowledge and ability, in the textile enterprises, scientific research, teaching and other departments engaged in textile design and development, textile design, textile production quality control, production and technological transformation and the initial management and management capacity Senior engineering and technical personnel.

Send your message to us

Ni-P Alloy Grooved Drum of Automatic Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords