New product energy-saving induction furnace price

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | induction furnace price 1.standard export packing 2.the goods is packed in wooden boxes |

| Delivery Detail: | Within 35 days after T/T payment of induction furnace price |

Specifications

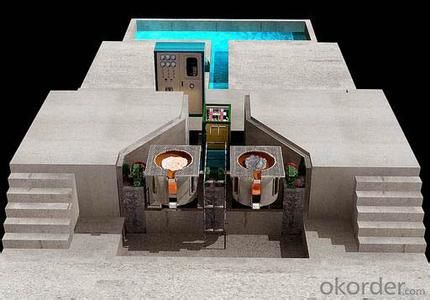

induction furnace price

1 Better water recycling and detecting system

2 Better electronic components and raw materials

Main parameter of 30T induction furnace price

| 30T/16000kw technical data induction furnace price | ||

| Item | Unit | Data |

| Rectifier | Pulses | 24 |

| Holding capacity | Ton | 30~35 |

| Maximun power | kw | 16000 |

| Energy consumption | kwh/ton(steel) | 550 |

| Rated input voltage | V | 1000 |

| Coil diameter | mm | 2200 |

| Coil voltage | V | 3500 |

| Rated frequency | Hz | 200 |

| Melting rate | Ton/h | 25 |

| Water pump capacity(furnace) | Ton/h | 300 |

| Water pump capacity(cabinet) | Ton/h | 150 |

| Cooling water pressure | Mpa | 0.2~0.3 |

| Inlet water temp. | °c | below 35 |

| Water temp. rise | °c | below 15 |

| Tilt | Hydraulic | |

Quality control of induction furnace price

To ensure that customers use our induction funace with no worries, hereby we warrant:

1. We strictly select good material to ensure the reliable quality.

2. Not only in the selection of materials, but also in every production procedures, we strictly act according to the ISO9001 standard, and control by full-scale inspection.

3. The Technical and specialized support from us will be available.

4. The upgraded products information will be timely supplied.

- Q: What is the difference between industrial furnaces and boilers?

- Hot water or steam generated in the boiler can directly provide necessary energy for industrial production and people's life, but also by the steam power device is converted to mechanical energy, or through the generator converts mechanical energy into electrical energy. Hot water boilers are called hot water boilers. They are mainly used in daily life, and are also used in industrial production. Steam generating boilers are called steam boilers, often referred to as boilers. They are used in thermal power stations, ships, locomotives and industrial and mining enterprises.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q: What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q: Why does the burner of industrial furnace burn occasionally?

- The general process for burner ignition, blowing furnace, electric spark ignition, solenoid valve, open the gas in case of delayed spark ignition, detection device detects the flame, the controller accepts signal so that the solenoid valve open, gas continuous normal combustion. However, if the ignition fails or the burner fires, the detector cannot detect the flame, which causes the solenoid valve to close and the burner flameout.

- Q: What are the advantages of a vacuum furnace?

- The accuracy of furnace temperature measurement and monitoring is obviously improved. The indicating temperature of the thermocouple and the temperature of the furnace reach 1.5 C. But there is a large temperature difference in a large number of workpieces in different parts of the furnace. If the forced circulation of the rarefied gas is adopted, the temperature range of the temperature range of + 5 DEG C can still be controlled.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

- Q: What is an industrial furnace pit?

- In twentieth Century 50s, coreless induction furnaces were developed rapidly. Later, electron beam kilns, using electron beams to impact solid fuels, strengthen the surface to heat and fuse materials with high melting point.

Send your message to us

New product energy-saving induction furnace price

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords