Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

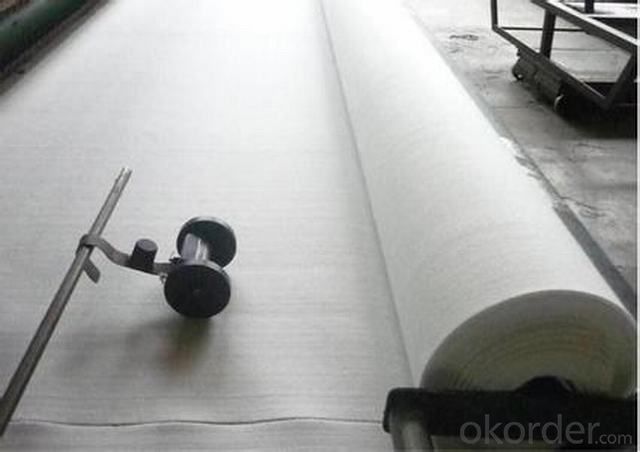

Product Description of Needle Punched Nonwoven Geotextile for Coast Engineering:

1. Specifications

1) Weight / Mass: 100gsm - 1500gsm

2) width: Within 8 m

3) longth: 50-100m/roll (at request)

4) Material: PP / PET

5) Color: Black , white , grey

6) Certification: CE/ISO9001

7) Manufacturing method: nonwoven / woven

2. Features

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment. It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

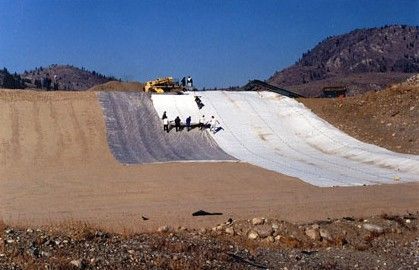

3. Geotextile Applications

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Coast Engineering?

The main application of our Needle Punched Nonwoven Geotextile for Coast Engineering is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for L Needle Punched Nonwoven Geotextile for Coast Engineering?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Coast Engineering with advanced equipment, big production capacity and excellent quality.

- Q: What can the geotext crushed material be used?

- Can continue to be used to do geotextile, but because the geotextile after the strength of the fiber is affected, can only be crushed after the geotextile for the production of low grade geotextile, for example, the national standard geotextile crushed material can generally be used Non-standard geotextile production, but in strict accordance with the proportion of added, should not add too much crushed material.

- Q: In ANSYS, geotextile what unit to simulate it?

- The use of shell units is relatively more reasonable.

- Q: What are the advantages of using geotextiles in shoreline stabilization projects?

- There are several advantages of using geotextiles in shoreline stabilization projects. Firstly, geotextiles provide effective erosion control by preventing soil erosion and sedimentation. They act as a barrier that stabilizes the shoreline and prevents the loss of valuable land. Secondly, geotextiles are permeable, allowing water to pass through while still retaining soil particles. This promotes natural drainage and prevents the accumulation of water behind the shoreline, which can cause further erosion. Additionally, geotextiles are durable and resistant to degradation from environmental factors such as UV radiation and chemicals. This ensures a long-lasting solution for shoreline stabilization. Lastly, geotextiles are cost-effective compared to traditional methods like concrete or riprap. They require less maintenance and are easier to install, making them a more practical and efficient choice for shoreline stabilization projects.

- Q: What is PAG in PAG composite geotextile

- Should be a high-strength glass fiber or grille and non-woven woven or bonded together geotextile, PAG is estimated that the product is a product code, one may be nominal vertical and horizontal strong, similar geogrid Such as PAG50-160, the other may be used cloth and grille specifications, such as 50kn grille and 160 grams of nonwovens

- Q: Can geotextiles be used for reinforcement in retaining walls?

- Yes, geotextiles can be used for reinforcement in retaining walls. Geotextiles are commonly used in retaining wall construction to provide strength, stability, and improved drainage. They help to distribute the load and prevent soil erosion while allowing water to pass through, making them an effective solution for reinforcing and enhancing the performance of retaining walls.

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been widely used in construction and civil engineering projects, including those located in seismic zones. They have proven to be effective in reinforcing soil, providing stability, and mitigating the impact of seismic events. Geotextiles can help improve the overall performance of structures by reducing soil liquefaction, enhancing soil drainage, and preventing soil erosion during seismic activities.

- Q: Can geotextiles be used in geogrid reinforced slopes?

- Yes, geotextiles can be used in geogrid reinforced slopes. Geotextiles are often used in combination with geogrids to provide additional reinforcement and prevent soil erosion in reinforced slopes. They help to distribute the load and improve the stability of the slope by acting as a separation layer between the soil and the geogrid.

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to provide soil reinforcement, erosion control, and drainage in various underground applications such as tunnels, basements, and underground storage facilities. Geotextiles can help improve soil stability, prevent soil erosion, and enhance the overall performance of the underground construction project.

- Q: What are the specifications for geotextiles and geogrids commonly used on expressways?

- You are the production, or sales, or procurement, the question asked, what model is the designer's decision

- Q: Can geotextiles be used for filtration of contaminants in water?

- Yes, geotextiles can be used for filtration of contaminants in water. Geotextiles are permeable fabrics that can effectively filter and separate particles, including pollutants, sediment, and other contaminants, from water. They are commonly used in various applications such as wastewater treatment, stormwater management, and erosion control to improve water quality by removing harmful substances.

Send your message to us

Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords