Needle Punched Geotextile Reinforced Linear Low-Density Polyethylene Geomembrane for Waste Liquids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

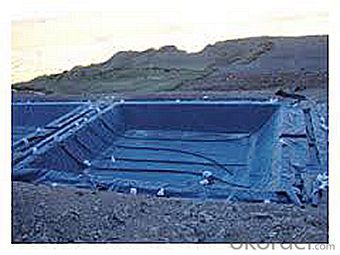

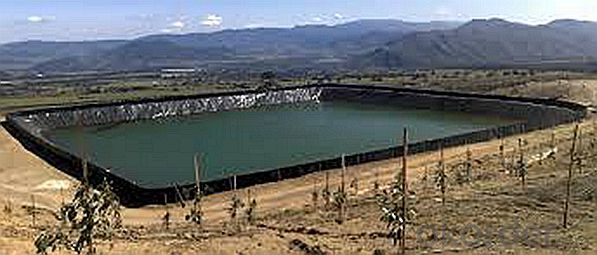

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

Specifications

professional,satisfied service , the most competitive price , the best product ,do as your requirement

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Geotextile 300g * 600mm * 300g is how is it?

- No you say 300g * 600mm * 300g this specification of the product, according to reason should be 300g * 0.6mm * 300g product 300g * 0.6mm * 300g product is a composite geomembrane specifications, also known as two cloth a film , Composite geotextile. That is, both sides of the upper and lower sides of a layer of 300g geotextile, the middle folder 0.6mm thickness of the plastic film. Composite geomembrane is to play the role of anti-seepage, generally used for water conservancy project seepage, civil engineering seepage and so on. The geotextile is from the water, reinforcement, protection, and can not achieve the role of anti-seepage. 300g * 0.6mm * 300g composite geomembrane price is generally between 11.5-13 yuan. You can do the next reference.

- Q: How do geotextiles improve the performance of retaining walls?

- Geotextiles improve the performance of retaining walls by providing reinforcement and stability to the soil behind the wall. They act as a barrier to prevent soil erosion and help distribute the load evenly, reducing the pressure on the wall. Additionally, geotextiles allow for the drainage of water, preventing buildup behind the wall and minimizing the risk of hydrostatic pressure, which can cause wall failure.

- Q: How do geotextiles help in sediment control?

- Geotextiles help in sediment control by acting as a barrier that traps sediment particles while allowing water to flow through. They prevent erosion by stabilizing the soil, and also help in filtration by retaining sediment and allowing clean water to pass.

- Q: What are the different factors that affect the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles. These include the type and quality of the material used in the geotextile, its thickness, weight, and strength. The installation technique and conditions, such as the soil type and slope, also play a significant role. Environmental factors, such as temperature, moisture, and chemical exposure, can impact the durability and effectiveness of geotextiles. Additionally, the design and engineering considerations, including the intended application and load requirements, should be taken into account when evaluating the performance of geotextiles.

- Q: What are the different geotextile installation techniques for roadways?

- There are several different geotextile installation techniques for roadways, including the overlay method, the trench method, and the sandwich method. - The overlay method involves placing the geotextile directly on top of the existing soil or subgrade before adding the new road material, such as asphalt or concrete. This technique helps to separate the soil layers and prevent the mixing of materials, providing stability and reducing the risk of road failure. - The trench method involves excavating a trench along the road alignment and placing the geotextile in the trench before backfilling it with soil or aggregate. This technique is commonly used for drainage applications, as the geotextile acts as a filter to prevent fine particles from clogging the drainage system, while allowing water to flow through. - The sandwich method is a combination of the overlay and trench methods. It involves placing a layer of geotextile between the existing soil and the new road material, as well as placing another layer of geotextile on top of the new road material. This technique provides additional reinforcement and separation, enhancing the overall performance and durability of the roadway. Overall, the choice of geotextile installation technique depends on the specific requirements and conditions of the road project, such as soil type, traffic load, and drainage needs.

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q: Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. These woven or non-woven fabrics can be employed to reinforce and stabilize sand dunes by trapping and retaining sand particles, preventing erosion caused by wind and water. Geotextiles offer a cost-effective and environmentally friendly solution for maintaining the integrity and resilience of coastal dunes, protecting them from erosion and promoting sustainable coastal management.

- Q: Can geotextiles be used in stormwater management systems?

- Yes, geotextiles can be used in stormwater management systems. Geotextiles are often used as a filtration and separation layer in stormwater systems to prevent soil erosion, filter out sediment and pollutants, and improve water quality. They can be installed in stormwater basins, retention ponds, and permeable pavement systems to enhance their effectiveness in managing stormwater runoff.

- Q: How do geotextiles interact with other geosynthetic materials?

- Geotextiles interact with other geosynthetic materials by complementing their functions and enhancing their performance. They can be used in conjunction with geogrids, geomembranes, and geocomposites to provide reinforcement, filtration, separation, and drainage capabilities. Geotextiles also help to prevent the intermixing of different soil layers and facilitate the flow of water, ensuring stability and long-term performance of geosynthetic systems.

- Q: How do geotextiles improve the performance of embankments?

- Geotextiles improve the performance of embankments by providing reinforcement, filtration, and separation. They prevent the intermixing of different soil layers by acting as a barrier, thus enhancing the stability and reducing the settlement of the embankment. Additionally, geotextiles allow for the efficient drainage of water, preventing the buildup of excess pore pressure that could potentially lead to embankment failure.

Send your message to us

Needle Punched Geotextile Reinforced Linear Low-Density Polyethylene Geomembrane for Waste Liquids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords