Aluminum Foil Facing Mylar Foil Shielding Foil for Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

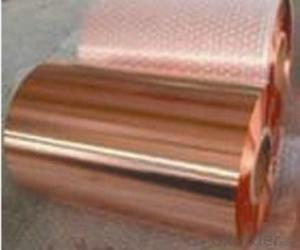

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: This question asks for a method to determine the thickness of an aluminum foil sheet.

- <p>To measure the thickness of an aluminum foil sheet, you can use a digital caliper or a micrometer. Place the foil between the jaws of the caliper and take the measurement. If you don't have these tools, you can use the 'multiple fold' method: fold the foil in half repeatedly and measure the total thickness after several folds, then divide by the number of layers to estimate the single layer thickness. For a more precise measurement, especially for thinner foils, consider using a thickness gauge designed for measuring thin materials.</p>

- Q: Describe the most effective method for folding aluminum foil edges to seal food packaging.

- <p>The best way to fold aluminum foil facing for food packaging involves a few simple steps. Start by placing the food in the center of the foil. Bring two opposite edges of the foil together over the food, ensuring they overlap slightly. Fold one edge over the other, creating a seam. Press down firmly to seal. Repeat this process with the remaining two edges, ensuring all edges are sealed tightly. For added security, you can fold the edges inward to create a double seam. This method prevents leakage and keeps the food fresh and protected during cooking or storage.</p>

- Q: This question asks for methods to clean the surface of aluminum foil facing, which is a type of material used in construction.

- <p>To clean aluminum foil facing, start by removing any loose dirt or debris with a soft brush. Then, use a mild detergent mixed with warm water and a soft cloth to gently wipe the surface. Avoid using abrasive cleaners or scrubbers, as they can damage the foil. For stubborn stains, a mixture of equal parts white vinegar and water can be applied with a cloth, followed by rinsing with clean water. Always let the surface dry completely to prevent water spots or damage.</p>

- Q: How should aluminum foil be stored after it has been used for cooking or food storage to keep it clean and ready for future use?

- <p>The best ways to store aluminum foil facing after using it for cooking or food storage involve cleaning and organizing it properly. First, wash the used foil with warm soapy water to remove any food residue. Rinse it thoroughly and pat dry with a clean towel. To store, roll the foil tightly starting from the center, keeping it compact and neat. Alternatively, you can store it in a resealable plastic bag or a dedicated foil container to keep it clean and prevent it from tearing. Always store it in a cool, dry place away from direct sunlight to maintain its quality.</p>

- Q: Can aluminum foil be utilized as a facing material for cooking in a microwave oven?

- <p>Aluminum foil facing should not be used for microwave cooking. Microwaves can cause the foil to heat up and potentially create sparks or even start a fire. It can also reflect microwaves, damaging the microwave's interior and potentially the oven itself. Always use microwave-safe materials, such as glass or microwave-safe plastic containers, for cooking in a microwave.</p>

- Q: Is it safe and practical to use aluminum foil with a reflective side to wrap raw meat?

- <p>Yes, you can use aluminum foil facing to wrap raw meat. Aluminum foil is a common and safe material for food packaging, including raw meats. The reflective side of the foil can actually help to keep the meat moist during cooking by reflecting heat. However, it's important to ensure that the foil does not come into direct contact with any open flames as it can cause a fire hazard. Additionally, when using foil for cooking, make sure to poke small holes in it to allow steam to escape, which can help prevent the foil from tearing or the meat from becoming too soggy.</p>

- Q: Is it safe and hygienic to repurpose a piece of aluminum foil that was previously used for wrapping food?

- <p>It is generally not recommended to reuse aluminum foil that has been in contact with food. Used foil can have residues of food, grease, and bacteria, which can contaminate new food items. Additionally, the foil can tear or become thin in areas, reducing its effectiveness and potentially allowing food to stick to previously used, contaminated areas. For椋熷搧瀹夊叏 and hygiene, it's best to use a fresh piece of aluminum foil each time.</p>

- Q: What is the most suitable material for food packaging that ensures safety and is also eco-friendly?

- <p>The best material for food packaging that is both safe and environmentally friendly is biodegradable or compostable material. Materials such as PLA (Polylactic Acid), made from renewable resources like corn starch, and paper-based packaging are preferred. They are non-toxic, compostable, and reduce plastic waste. Additionally, materials like glass and metal can be recycled and are also considered safe for food contact. However, it's crucial to consider the entire lifecycle of the packaging to ensure it's truly sustainable.</p>

- Q: Explain the differences between aluminum foil facing and other types of food wrap.

- <p>Aluminum foil facing is a type of food wrap that is made from thin sheets of aluminum, which provides excellent barrier properties against air, moisture, and light. It is often used for cooking, baking, and preserving food. Unlike plastic wraps, it does not stick to food and can withstand high temperatures without melting. Other types of food wraps, such as plastic or cling wraps, are made from polymers and are not heat resistant. They are typically used for short-term food storage and are not suitable for cooking. Paper-based wraps, like parchment or wax paper, are used for baking and providing a non-stick surface but do not offer the same barrier properties as aluminum foil.</p>

- Q: Is it possible to use aluminum foil facing as a wrap for lunch boxes?

- <p>Yes, you can use aluminum foil facing to make a wrap for lunch boxes. Aluminum foil is a versatile material that is commonly used for food packaging due to its ability to keep food fresh and protected. It's lightweight, easy to use, and can be wrapped around food items to keep them insulated and prevent spills. However, it's important to ensure that the foil is food-grade and clean before use to maintain food safety.</p>

Send your message to us

Aluminum Foil Facing Mylar Foil Shielding Foil for Coaxial Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords