Msc Aluminum Sheets - Aluminium Composite Panel for Insulation Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

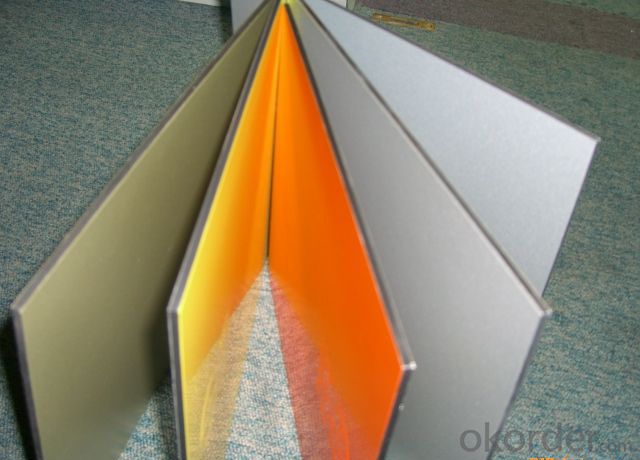

Structure of Aluminium Compoosite Pannel for Insulation Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Compoosite Pannel for Insulation Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Compoosite Pannel for Insulation Application:

Aluminium Compoosite Pannel for Insulation Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is lightweight, durable, and corrosion-resistant, making it an excellent choice for modular construction applications. It is commonly used for building facades, roofing, and structural components in modular construction due to its strength-to-weight ratio and ease of installation.

- Q: what's the oxidation method of positive pole on the surface of aluminum sheet?

- Do chemical polishing again, oxidation time is about 40 – 90 minutes, after finishing all of these, you can conduct positive pole oxidation, choose sulfuric acid solution in normal situation, pretreatment is very important in the whole process, take stereo as negative pole, firstly, use the solution mixed of carbonate-bicarbonate and detergent to heat and clean its surface, pretreat the aluminum sheet, dyeing according to requirement after oxidation, then remove the oxide film with oxide film removal solution, place aluminum sheet on the positive pole, finally closing it in the boiling water for about 15 minutes.

- Q: Okay, so i swallowed some aluminum foil like the size of a quarter from my fruit rollup wrapper, ha don't ask why? but my stomach KINDA hurts right now...like 2 minutes later.. Could this have done any damage to me.?

- You'll be fine! It should ball up and you'll eventually pass it! (BLAH) My dog actually ate an entire aluminum foil cupcake tin once! He passed it in a day or 2 (Not that I'm comparing you to a dog! But same kinda thing!) Your stomach kinda hurts probably cause you're freaking out! Our minds like to play tricks on us that way. But if you end up getting lower abdo pain in the next 12-24 hours (sharp, stabbing) then better get it checked out! Good Luck! Watch out for those wrappers next time! ha

- Q: How is the strength and durability of aluminum sheets determined?

- The strength and durability of aluminum sheets are determined through various tests and measurements such as tensile strength, hardness, impact resistance, and corrosion resistance. These tests help evaluate the ability of the aluminum sheets to withstand external forces, deformation, wear and tear, and environmental factors. Additionally, the composition and manufacturing process of the aluminum sheets also play a crucial role in determining their strength and durability.

- Q: When Aluminium nitrate is heated , i got yellow amorphous solid which did not not melt on further heating. What compound is that?

- l would say you have mostly aluminum oxide as a product which probably contains some Nitrogen dioxide gas, a second product of the decomposition of aluminum nitrate. If I were you I would not heat nitrate salts as they can explode upon heating. they also need to be kept away from any kind of reducing agent such as powdered metals, or any fuels, reactions can be violent.

- Q: What is the use?

- A series of 1000, representing the 1050106010701000 series aluminum is called pure aluminum, all in series 1000 series aluminum content belongs to one of the largest series. The purity can reach more than 99%. Because the technology does not contain other elements, the production process is relatively simple, the price is relatively cheap, is most commonly used in the conventional industry a a series of circulation on the market for most of the 1050 and 1060 series.1000 series aluminum plate to determine the minimum aluminum content in this series according to the amount of the last two Arabia figures, such as the 1050 series of the last two Arabia number 50, according to the international brand naming principles, content must reach to the top 99.5% qualified products. Aluminum Alloy technical standards China (gB/T3880-2006) is also clear that the aluminum content of 1050 aluminum content reached 99.5%. the same 1060 series aluminum must reach above 99.6%.The two and 2000 series aluminum 2A16 (LY16) 2A06 (LY6) features of 2000 series aluminum is high hardness, which belongs to the copper content is the highest, probably around 3-5%.2000 series aluminum plate belongs to aviation aluminum, currently in the conventional industries should not be used. Our current production of 2000 series aluminum manufacturers quality can not less. Compared with foreign countries. Currently imported aluminum is mainly provided by the production enterprises of South Korea and Germany. With the rapid development of China's aerospace industry, aluminum production technology of the 2000 series will be further improved.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Fiberglass Bass Boats

- Q: Are aluminum sheets suitable for lighting fixtures?

- Yes, aluminum sheets are suitable for lighting fixtures. Aluminum is a lightweight and durable material that can be easily shaped and manipulated to create various designs for lighting fixtures. It also has excellent heat dissipation properties, which is crucial for ensuring the longevity and performance of lighting fixtures. Additionally, aluminum is corrosion-resistant, making it suitable for both indoor and outdoor lighting applications.

- Q: Can aluminum sheets be painted after installation?

- After installation, it is indeed possible to paint aluminum sheets. Aluminum, being a highly versatile and durable material, can be painted for the purpose of improving its appearance or harmonizing it with the surrounding environment. However, it is crucial to adequately prepare the surface before painting in order to ensure that the paint adheres well and lasts long. This typically involves cleaning the surface, eliminating any dirt or debris, and applying a suitable primer to enhance paint adhesion. Once the surface is prepared, various types of paint can be used on the aluminum sheet, such as acrylic, oil-based, or epoxy paint. To achieve the best results, it is advisable to seek guidance from a professional painter or carefully follow the instructions provided by the paint manufacturer.

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

Send your message to us

Msc Aluminum Sheets - Aluminium Composite Panel for Insulation Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords