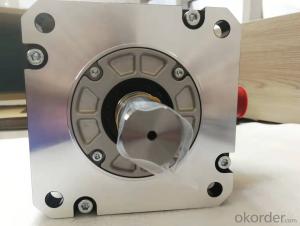

Mitsubishi Motor With Electromagnetic Brake HG-KR43BJ For Injection Molding

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1350 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Servo motor series: low inertia, medium / high power. Rated output: 7.0kw.

Rated speed: 3000r / min. electromagnetic brake: with.

Shaft end specification: Standard (straight shaft).

Features: low inertia, suitable for high-speed, high acceleration and

deceleration operation, Mitsubishi servo motor user manual. IP rating: IP67.

Application example:

1. Food processing machinery.

2. Printing press.

3. Injection molding machine (11kw, 15kw) hg-kr43bj

4. Large stamping machine (11kw, 15kw)

The protection grade of hf-sp / hf-jp series motor is IP67 (except the shaft

through part).

Low inertia medium power servo motor (0.5KW ~ 9kw), maximum speed: 6000r / min

(rated speed: 3000r / min),

It is suitable for high-frequency positioning and acceleration / deceleration

operations, especially the user manual of Mitsubishi servo motor of food

processing machine and printing machine. Low inertia high-power servo motor

without cooling fan (11kw and 15kw), maximum speed: 3000r / min (rated speed:

1500r / min). The design without cooling fan is adopted by the dry motor to

make the motor structure more compact, and the wiring is reduced by using power

connector (compared with hf-lp series servo motor with the same power, the

volume is reduced by about 46% and the weight is reduced by about 34%)

It is suitable for high-frequency positioning and acceleration / deceleration

operations, especially the user manual of Mitsubishi servo motor for injection

molding machine and large press. Hf-jp703 (4) / 903 (4) maximum speed: 5000r /

min, servo motor series: low inertia, medium and large capacity. Rated output:

1.5kw.

Rated speed: 3000r / minhg-kr43bj user manual. Electromagnetic braking:

Rated speed: 3000r / minhg-kr43bj user manual. Electromagnetic braking:

without. Power supply: 200V.

High frequency operation or high acceleration and deceleration operation of

medium, large capacity and low inertia products. To improve the environmental

resistance, hg-sr and hg-jr series products adopt IP67 High speed & high

torque. Shorten positioning time and realize high-speed equipment. In 100

sites, there are 100 different drive controls. In order to meet diversified and

detailed on-site needs as much as possible,

In the distribution of mr-14 product line, we provide rich user manual books of

CO serving amplifier and co serving motor products hg-kr43bjj, which can meet

the different needs of different customers. Motor series: low inertia, medium

power. Rated output power: 11.0kw. Rated speed: 2000r / min. With brake or not:

No.

Shaft end: Standard (straight shaft) hg-kr43bj user manual. Voltage: 400V type.

Protection level: IP65 (IP67).

Features: low inertia, from low speed to high speed, three modes can be

selected, suitable for different application ranges. As a standard production

port, 30kW or higher power is suitable for flange (type) installation and foot

installation.

Application examples: injection molding machine, semiconductor manufacturing

device, large conveying machinery. High resolution encoder 131072p / rev (17

bits).

High resolution encoder is included to ensure excellent performance and

stability at low speed.

All motors are the same size as the previous products and the wiring is

compatible. Servo motor series: low inertia, medium / high power, rated output:

50.0kw. Rated speed: 1500r / min. Electromagnetic brake: none.

Shaft end specification: Standard (straight shaft). Voltage: 400V level.

Features: there are three types of low inertia, medium and high speed models,

which are suitable for different applications as the standard. Motors of 30kW

and above can be installed with flanges or brackets. Hg-kr43bj manual.

IP level: IP44 Mitsubishi servo motor user manual.

Application example:

1. Injection molding machine.

2. Semiconductor manufacturing equipment.

3. Large material conveying system.

4. Press.

The rich motor product line can optimize the performance of the machine.

It has a rich product line of Shenji, including rotary servo motor, linear

servo motor and direct drive Shenji.

- Q: Electrical system in a residential building. When we use any equipment on one phase the lights on that phase dim down but and the same time the lights on the second phase become brighter.

- The voltage on loaded phase dips on the account of starting current of equipment. This problem is specifically critical in case of motors. So the dimming brightening happens because of unbalance is 3 phases of the installation. This condition is completely normal keeps happening always.

- Q: I understand that the frequencies emited from cell phones can interfere with the electrical equipment in ICU's; however, why can't patients have regular phones in ICU's; regular chord phones shouldn't emit frequencies or do they?

- interesting question. you are right regular phones do not/should not emit frequencies that would interfere with any equipment.as far as I know I do not know why you are not allowed a phone in your ICU, I have always had a phone link immediately.and that was in ICU as well how else is family supposed to stay in touch? I do not believe that it is dis-allowed as a general rule you might want to double check the reason the dr/hospital staff gave you. hope this helps to answer the question good luck

- Q: I am currently going to school to study Engineering. I want to become an Electrical Engineer, but recently, I've heard about Electronics Engineering. I did telecommunications in the US military and dealt with small circuits and RF communications equipment. This all falls under Electronics Engineering.I've been trying to find more info on Electronics Engineering, but can't seem to find if it is a separate degree program from Electrical Engineering.My school only lists:Electrical Engineering Computer ScienceElectrical Engineering Computer Sci - Materials Sci EngineeringElectrical Engineering Computer Sci - Nuclear EngineeringHow would I go about becoming an Electronics Engineer?

- My okorder

- Q: construction, agricultural, forestry, medical, electrical HVAC etcwhat it will be the best name for a business that it will supply some agency with all kind of equipment ( for all possible industries and activities)

- Well a business aproach will definitely be your best bet. Nothing fancy. You should spend some time brainstorming. Maybe check out some other companies name's for inspiration. Maybe stick the last name of the company owner (you?) in part of the name. Basically just spend some time thinking.

- Q: I have a garage full of my dad's old equipment from oscilloscopes, amplifiers, circuit board materials, etc. that I don't know what they are/or are worth, or how to go about selling. Does anyone have any suggestions other than listing everything individually (there is a lot) on OKorder or CraigsList? I'm leaning towards hiring someone to come in and auction it all off for me, but need suggestions.Thanks!

- There is a good chance that if it is old equipment, it won't be worth much. There is also a chance that some of the old amplifiers and circuit board materials contain hazardous material or chemicals that need to be disposed of properly. A first step would be to take the parts numbers off the equipment and enter them into google. There is a good chance that the stuff you have is not going to be worth anything, if there are pieces that are worth much you could sell those, and then ship the worthless stuff off to a electronics recyclers.

- Q: I have a piece of electrical equipment at a voltage potential of 277VAC to ground. Due to hardware problems I have an air gap of 3/8 from ground to 277VAC when it used to be one inch. Please advise if I am safe to leave it that way or should I add insulation.

- That is ok with respect to any possible arc. But there may be other reasons to add insulation. Safety for example. If it's easy to add the insulation, do it. .

- Q: I cut a deal with my electrical shop teacher. If i tell him how we can relate an electrical class to ski lifts and snowmaking and learn about how they work and the electrical portion of them then hell take my shop to our local mountain Wachusett. Can anyone tell me how ski lifts and snowmaking equipment work and how i can relate it to electrical

- Most ski lifts drive their cables from an electric motor. (This provides efficient torque control and emergency shut-down capability.) Snow making equipment uses electric drives for the water pumps and air compressors. (They make snow by freezing a sprayed water mist with the expansion cooling of the compressed air.)

- Q: I have just recently started getting electric shocks at random times when working with my tank. The first time it happened i was wearing a rubber glove (which i thought would block electricity in the first place) i put my hand in the sump and it tore through the glove and shocked my whole arm. The next day i was using the net in the tank itself and got a big shock, then the same thing happend to my brother, my girlfriend and my friend all at different random times. It feels like one of those trick handshake or trick lighters that people have but it hurts way more. Basically the shock runs through my arm and into my chest, leaving my arm numb.I have a 72 gallon bowfront saltwater set up with live rock, about 15 fish, the whole deal. I have the coralife 260 watt compact fluorescent light hood with moon lights attatched with plastic legs on top of the aquarium over the glass canopy. I have an 850 gph pump in the sump, a 300 watt heater in the pump and a protein skimmer in the sump.

- Yikes! Your problem is actually not that uncommon, but certainly unpleasant none the less. It's definitely attributed to faulty electrical equipment. Any equipment that's submerged under water could be the culprit, so I would narrow it down to the pump, heater, or skimmer. You can test for stray voltage using a voltage tester or volt meter set to read AC voltage (VAC) by putting one lead on a known ground and the other in the tank water. To further isolate the problem, plug in each piece of electrical equipment one at a time while testing for voltage. Once you've determined which equipment is faulty, simply replace it. In the mean time, you may also want to install an Ultra-Ground Titanium Probe in your sump. Please note that I am not an electrician, just a fellow hobbyist, so if you are uncomfortable performing any of the above steps, I would strongly encourage you to have a certified electrician look at your problem. Stray voltage not only harms you, but it may harm the fish too. It has been attributed to fish health problems like lateral line disease, fin erosion, and gill deterioration. In the mean time, be sure to turn off all electrical equipment before working inside the tank. Regards

- Q: for example, a 3ds?

- There is a video on youtube of how to take apart a 3ds. This might make you void your warranty.

- Q: can an odd electrical field produce a link with the energy of those said to be at rest?can a electrical field be contained a directed within ones body.have you ever experienced truelly odd static or electrical fenomena around you?

- Yes We are energy Every animal, plant and object is made of energy.

Send your message to us

Mitsubishi Motor With Electromagnetic Brake HG-KR43BJ For Injection Molding

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1350 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches