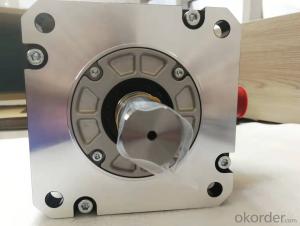

Standard Straight Shaft Low Inertia HG-KR43J Motor For Large Stamping

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Servo motor series: low inertia, medium / high power. Rated output: 5.0kw.

Rated speed: 3000r / min. Electromagnetic brake: none.

Shaft end specification: Standard (straight shaft).

Features: low inertia, suitable for high-speed / high acceleration and

deceleration operation. IP rating: IP67. Application example:

1. Food processing machinery.

2. Printing press.

3. Injection molding machine (11kw, 15kw).

4. Large stamping machine (11kw, 15kw) hg-kr43j

The protection grade of hf-sp / hf-jp series servo motor is IP67 (except the

shaft through part).

Low inertia medium power servo motor (0.5KW ~ 9kw), large speed: 6000r / min

(rated speed: 3000r / min), suitable for high-frequency positioning and

acceleration / deceleration operations, especially food processing machines and

printing machines.

Low inertia high-power servo motor without cooling fan (11kw and 15kw), high

speed: 3000r / min (rated speed: 1500r / min). Due to the design of no cooling

fan, the motor structure is more compact, and the wiring is reduced by using

the power connector (compared with the hf-lp series servo motor with the same

power, the volume is reduced by about 46% and the weight is reduced by about

34%), which is suitable for high-frequency positioning and acceleration /

deceleration operations, especially injection molding machines and large

presses.

Hf-jp703 (4) / 903 (4) high speed: 5000r / min, servo motor series: flat type,

medium capacity. Rated output: 5.0kw.

Rated speed; 2000r/min。

Electromagnetic braking: attached. Power supply: 200V.

It is suitable for limiting the installation space in medium capacity and flat

products.

To improve the environmental resistance, hg-kr, hg-mr, hg-rr and hg-ur series

products adopt IP65. In 100 sites, there are 100 different drive controls. In

order to meet diversified and detailed site needs as much as possible,

In the configuration of mr-j4 product line, it provides rich servo amplifier

and servo motor products. It can meet the different needs of different

customers. Servo motor series: medium inertia, small capacity. Rated output:

0.5KW.

Rated speed: 2000r / min. Electromagnetic braking: attached. Power supply:

400V.

Realize the stable driving of medium capacity and medium inertia products.

Through the optimized structural design, the small total length in the industry

is realized.

High speed & high torque. Shorten positioning time and realize high-speed

equipment. Reduce power on torque ripple.

Through the combination of slot speed and torque, the smooth operation of the

motor can be further reduced.

To improve the environmental resistance, hg-sr and hg-jr series products adopt

IP67. Servo motor series: low inertia, medium power. Rated output: 0.5KW.

Rated speed: 2000r / min

Electromagnetic brake: with.

Shaft end specification: Standard (straight shaft).

Features: low inertia, widely used in general machinery. IP grade: IP65.

Application example:

1. Roller feed equipment.

2. Load / unload equipment.

3. High frequency transmission system.

The rich motor product line can optimize the performance of the machine.

It has a rich motor product line including rotary servo motor, linear servo

motor and direct drive motor

- Q: What is relay?

- A relay is an electronic control device that has a control system and a controlled system, usually used in an automatic control circuit, which is actually an "automatic switch" that uses a smaller current to control a larger current. So in the circuit plays an automatic adjustment, security protection, conversion circuit and so on.

- Q: Human body infrared sensor module to connect the electrical method

- Typical applications are right. You can add a step-down resistor 9V down to 3V, and then connected to the relay.

- Q: Does the PLC relay output have input restrictions? How much is the output frequency?

- PLC relay output, the frequency is usually best not to exceed 1Hz, some instructions that can reach 0.1Hz, it is not a long time. As for input? If you refer to the load of the relay, it is AC and DC universal, AC voltage should not exceed 240V Under normal circumstances is allowed, DC, then use 48V in the vast majority of occasions enough. And the current will look at the species, and usually do not exceed 1A is better, some instructions that can reach 5A or even 10A, because the arc relationship is still not a long-term plan. Especially if you want high-frequency output, the current is still smaller. If you are referring to the relay type output of the PLC switch input section, then it is still the most common use of DC 24V.

- Q: The main components of the relay

- Thermal Reed Relays are a new type of thermal switch that utilizes thermo-sensitive magnetic materials to detect and control temperature. It consists of temperature magnetic ring, constant magnetic ring, reed switch, thermal installation, plastic substrate and some other accessories. The thermal reed relay does not use the coil excitation, and the magnetic force generated by the constant magnetic ring drives the switch action. Whether the permanent magnetic ring can provide magnetic force to the reed switch is determined by the temperature control characteristics of the temperature magnetic ring. The reed relay is a relay that generates a magnetic field by a coil to act as a coil sensing device. So the characteristics of reed relays, small size, light weight, fast response time, short beating time and other characteristics.

- Q: The left side of the 6 input and output contacts on the right there are 4 input and output contacts have any use

- 6 contacts connected to the main circuit, 4 contacts control circuit

- Q: What is a heating relay?

- The working principle of the thermal relay is caused by the heat flowing into the heat element, so that the bimetal with different expansion coefficient is deformed. When the deformation reaches a certain distance, the connecting rod is pushed to make the control circuit open, so that the contactor Power failure, the main circuit off, to achieve the motor overload protection. 1, mainly used for overload protection of the asynchronous motor, the working principle is the overload current through the thermal components, the bimetal heating to bend the action to promote the action mechanism to drive the contact action, so the motor control circuit to disconnect the motor to achieve power off , Play the role of overload protection. 2, in view of the bimetallic heating process, the heat transfer takes a long time, therefore, thermal relay can not be used for short circuit protection, but can only be used as overload protection thermal relay overload protection.

- Q: Our company some time ago into the batch of electrical out of the fault, from time to time abnormal heat how to do, please help you heroes

- "solutions" 1. Power supply voltage and coil voltage drop will cause repeated switching and vibration occurs, resulting in abnormal heat. In particular, AC specifications of the relay, the voltage should not be less than 90% of the rated voltage. DC specifications of the relay, the voltage should not be less than 70% of the rated voltage (with the relay model will be somewhat different). ????(Example: motor, etc., the high current in line with the operation of the moment, sometimes resulting in low power supply voltage) Please be careful not to control the relay coil ON / OFF sensors and switches, micro-use of computer malfunction caused by high frequency switch. 2. Exceed the contact rated current: In order to prevent the current above the rated current above the contact circuit flow, please design the circuit safely. 3. Coil overvoltage application:

- Q: Time relay time to complete, is to maintain the final state or start timing? The There is a time relay a power, often open contact on the closed, or timing is completed before closing?

- Time relay time to complete, to maintain the final state can be. Time Relay: Time relay refers to a relay that produces a jumping change (or contact action) when the output circuit is subjected to a predetermined exact time after adding (or removing) the input action signal. Is an electrical component that is used to circuit on a lower voltage or a smaller current that is used to turn on or off a circuit with a higher voltage and a larger current. At the same time, the time relay is also a use of electromagnetic principle or mechanical principle to achieve delay control of electrical control. It is a lot of type, with air damping type, electric type and electronic type.

- Q: What is a Type A relay?

- Type B relays Type B relays are single pole single throw type, the default state is "normally closed".

- Q: The principle of the relay I know. I found some information. Said it is often closed to protect the circuit. How to protect I do not understand this sentence. The relay is not a small current to control the high current thing. If a 12V control power is connected to the relay, keep the relay coil constant. As long as there is always a current, the relay should not be broken off normally open point. So the machine is a failure "such as: connected." Often closed point should not be broken into a very open point ah. what is the problem?

- Simply said: relay in the non-power state, the closure of a pair of contacts is often closed point, disconnect a pair of contacts is often open point, the relay coil voltage, the normally closed, normally open closed to achieve conversion The If the coil is always in the power state, the coil will be hot, of course, the relay itself is allowed to a certain temperature rise, but often when the power plus the ambient temperature, the relay life will be affected, heat for too close to other electronic components, Will be affected. Therefore, in the application should be considered on-off time ratio. You describe the problem of equipment failure is not clear, you should look at the specific application of reanalysis.

Send your message to us

Standard Straight Shaft Low Inertia HG-KR43J Motor For Large Stamping

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches