Tru Timber Mirror Aluminum Coil/Strip for Lighting Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mirror Aluminum Coil/Strip for Lighting Decoration

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Mirror Aluminum Coil/Strip for Lighting Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mirror Aluminum Coil/Strip for Lighting Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

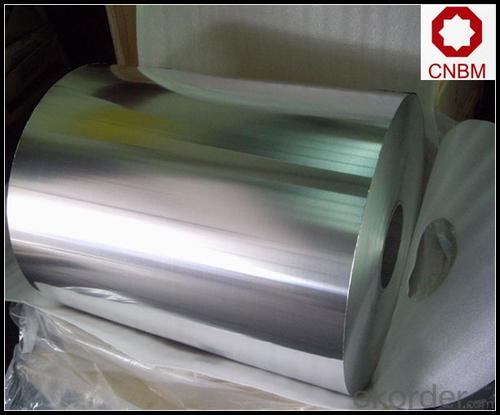

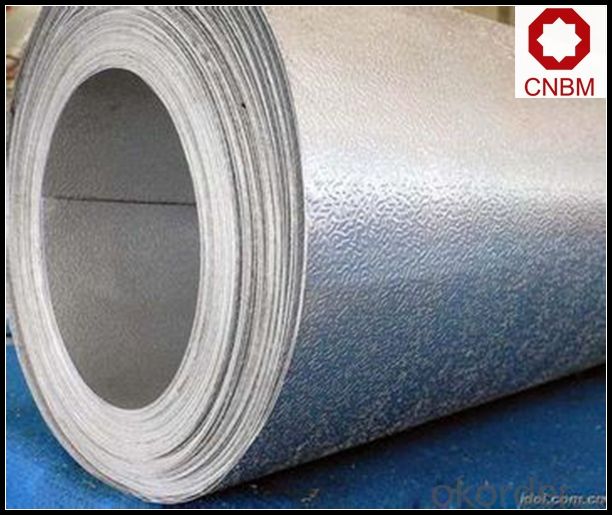

5. Image of Mirror Aluminum Coil/Strip for Lighting Decoration

6. Package and shipping of Mirror Aluminum Coil/Strip for Lighting Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are certain restrictions on the coil thickness of aluminum coils. The thickness of aluminum coils may vary depending on the specific application and manufacturing process. However, it is generally limited by practical constraints such as the equipment capabilities, handling and transportation considerations, and the desired properties of the final product.

- Q: Are aluminum coils resistant to impact damage?

- Yes, aluminum coils are generally resistant to impact damage. Aluminum is a lightweight and durable material that can withstand minor impacts without getting damaged. However, excessive force or strong impacts may still cause damage to the coils.

- Q: Are aluminum coils suitable for soundproofing applications?

- Aluminum coils are not typically used for soundproofing applications. While aluminum is a good conductor of heat and electricity, it does not have the same sound-dampening properties as other materials commonly used for soundproofing, such as foam, rubber, or dense fibers. These materials are specifically designed to absorb and block sound waves, reducing noise transmission. Aluminum coils, on the other hand, are often used in HVAC systems or as a material for building exteriors due to their durability and heat transfer capabilities. Therefore, if soundproofing is the main objective, it is recommended to consider other materials that are specifically designed for that purpose.

- Q: My school has lunched catered in daily because it cuts down on staff in the kitchen. The food is delivered in individual aluminum containers for each student. In doing so, the school uses 99,000 aluminum trays in one school year, all of which get thrown away. I'm trying to find an alternative such as biodegradable food containers. Does anyone have any ideas? The container has to be able to withstand the heat of an oven.

- Aluminum is very recyclable and profitable to do so. It takes 95% less energy to recycle aluminum then to create new aluminum. I doubt that you will find a better alternative that will withstand oven heat. You need to start a recycling program

- Q: How much is one square aluminum gate and five hard door?

- On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: How are aluminum coils used in the production of cans and containers?

- Aluminum coils are used in the production of cans and containers as they are rolled into thin sheets that can be shaped into the desired form. These coils are fed into a machine where they are cut, formed, and joined together to create the body of the can or container. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for packaging, ensuring the preservation and protection of the contents inside.

- Q: This question seeks advice on methods to prevent rust formation on aluminum coils.

- <p>To prevent rust on aluminum coil, ensure proper storage conditions by keeping the coils dry and avoiding contact with moisture. Use protective coatings or sealants that are compatible with aluminum to create a barrier against the elements. Regularly inspect the coils for signs of corrosion and clean them with a non-abrasive cleaner to remove any contaminants. Avoid using harsh chemicals that could accelerate oxidation. Maintain good ventilation in storage areas to reduce humidity, which can contribute to rust formation. Finally, consider using anodizing or other surface treatments that enhance the aluminum's natural resistance to corrosion.</p>

- Q: Can aluminum coils be welded or soldered?

- Aluminum coils possess the capability of being both welded and soldered. The fusion of aluminum coils can be achieved through welding or soldering, which are two widely employed techniques in this regard. Welding entails the melting of the aluminum material within the coils, followed by the application of heat and pressure to bind them together. This particular procedure necessitates the utilization of specialized equipment and skilled operators. Conversely, soldering is a process that utilizes solder, a filler material with a lower melting point, to connect the aluminum coils. Soldering is commonly employed in lighter applications and necessitates less heat compared to welding. Both welding and soldering are effective methods for joining aluminum coils. However, the selection between these two techniques depends on the project's specific requirements, the availability of equipment, and the proficiency of the operator.

- Q: How are aluminum coils used in the production of heat sinks?

- The excellent thermal conductivity and malleability of aluminum coils make them indispensable in the production of heat sinks. Heat sinks are designed to dissipate excess heat from electronic components like processors, integrated circuits, and power transistors. By using aluminum coils in the manufacturing of heat sinks, several key advantages can be gained. First and foremost, aluminum coils possess high thermal conductivity, enabling efficient heat transfer from electronic components to heat sinks. This is crucial for maintaining optimal operating temperatures and preventing performance degradation or permanent damage caused by excess heat. The high thermal conductivity of aluminum ensures quick dissipation of heat away from electronic components, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various heat sink designs. Heat sinks come in different sizes and shapes, with the most common being finned heat sinks. Fins on the heat sink increase surface area, facilitating greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling effective heat release into the surrounding environment. Furthermore, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that heat sinks do not add significant weight to electronic devices, which is especially important in applications with weight restrictions, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum guarantee the durability and longevity of heat sinks, even in harsh environments. In conclusion, aluminum coils are vital components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion resistance. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately extending the lifespan of electronic devices.

Send your message to us

Tru Timber Mirror Aluminum Coil/Strip for Lighting Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords