Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

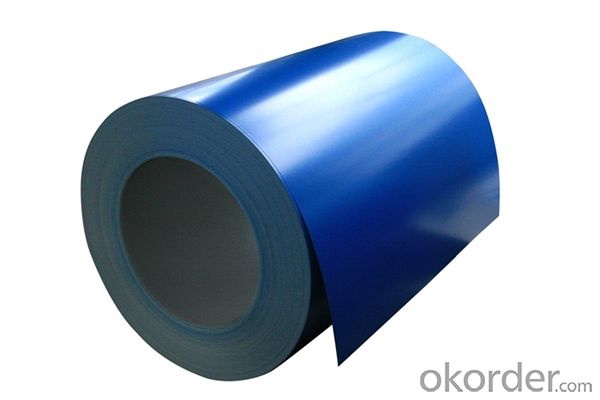

1. Structure of Mill Finished PVDF Coating Aluminium Coil from China Description

Mill Finished PE Coating Aluminium Coil is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coating Aluminium Coil from China

Mill Finished PE Coating Aluminium Coil | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

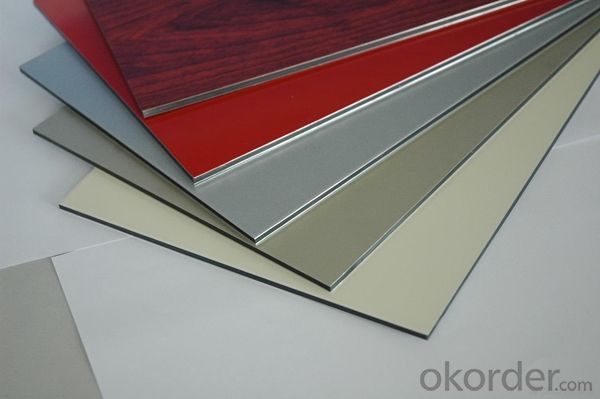

3. Application of Mill Finished PVDF Coating Aluminium Coil from China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coating Aluminium Coil from China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coating Aluminium Coil from China

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Mill Finished PVDF Coating Aluminium Coil from China

7. Package and shipping of Mill Finished PVDF Coating Aluminium Coil from China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: I'm doing a science project on Aluminum and need to know what the other metals are in the following ores:BauxiteCryoliteGibbsiteI have to know what percentage of it is which metal. Don't know if that makes much sense, but I really need help because I can't find the answer anywhere. Thanks :D

- The bauxite is a sedimentary rock of chemical origin composed for the most part by alumina (Al2O3) and, in smaller measure, iron oxide and silica. It is the main aluminum source used by the industry. It is a residual taken place by the meteorización of the igneous rocks under conditions geomorfológicas and climatic favorable. Molecular formula: Na3AlF6 Synonym: Fluoroaluminato of sodium. Chemisorption of catechol on gibbsite, boehmite, and noncrystalline alumina... Alumina; Aluminium Oxyhydroxyde

- Q: Related technical standards of aluminium coil

- GB/T 10456-1989 anodized aluminium foilGB/T 9734-1988 chemical reagent -- General method for the determination of aluminiumGeneral specification for GB/T 9538-1988 strip cable connectorsComplexometric titration fluoride release method for the determination of three aluminium oxide content in GB/T 9489.4-1988 corundum powder twoGB/T 9438-1999 aluminium alloy castingsGB/T 8733-2000 cast aluminium alloy ingotsGB/T 6454-1986 getter aluminium zirconium alloy rings and sheets

- Q: What are the strength properties of aluminum coils?

- The strength properties of aluminum coils include high tensile strength, excellent formability, and good resistance to corrosion. Aluminum coils have a high strength-to-weight ratio, making them a preferred choice in various industries such as automotive, aerospace, and construction. They exhibit good resistance to fatigue and are capable of withstanding heavy loads without deformation or breakage. Additionally, aluminum coils offer excellent formability, allowing for easy shaping and bending without compromising their structural integrity. Moreover, aluminum's natural oxide layer provides a protective barrier against corrosion, making aluminum coils highly resistant to rust and other forms of degradation. Overall, the strength properties of aluminum coils make them a versatile and reliable material for a wide range of applications.

- Q: Are aluminum coils suitable for reflective insulation?

- Indeed, reflective insulation can indeed benefit from the use of aluminum coils. With its high reflectivity and low emissivity, aluminum proves to be an excellent material for deflecting radiant heat. By effectively reflecting radiant energy away from the insulated area, aluminum contributes significantly to reducing heat transfer. Unsurprisingly, aluminum coils find widespread application in various reflective insulation solutions, including foil-faced insulation boards and radiant barriers.

- Q: What are the different types of surface treatments for corrosion resistance?

- Various materials can benefit from different surface treatments to enhance their resistance to corrosion. These treatments can be grouped into mechanical, chemical, and electrochemical methods. 1. To improve corrosion resistance, mechanical surface treatments involve physically altering or modifying the material's surface. Shot peening, sandblasting, and polishing are common methods. Shot peening induces compressive stresses by bombarding the material with small metal pellets, preventing corrosion. Sandblasting removes existing corrosion and creates a clean, smooth surface by blasting it with abrasive particles. Polishing, using abrasives, creates a smooth, reflective surface that reduces the chances of corrosion initiation. 2. Chemical surface treatments involve applying a chemical solution or coating to create a protective layer against corrosion. Chromating, for example, applies a chromate conversion coating that acts as a barrier against corrosion and improves adhesion for subsequent paint or coating layers. Anodizing, commonly used for aluminum surfaces, creates a thick oxide layer that enhances corrosion resistance and can provide decorative finishes. Other chemical treatments, like phosphating, passivation, and galvanizing, use specific chemical solutions or coatings to protect against corrosion. 3. Electrochemical surface treatments utilize electrochemistry principles to create a protective layer. Electroplating involves depositing a thin layer of a more corrosion-resistant material, such as zinc, nickel, or chromium, onto the base material's surface. Anodic protection connects a sacrificial anode to the material, causing the anode to corrode instead of the material itself. This method is commonly used for underground structures and pipelines. The choice of surface treatment for corrosion resistance depends on factors like the material, intended application, and desired level of protection. It is crucial to consider factors like cost, environmental impact, and performance requirements when selecting the appropriate treatment, as each method has its advantages and limitations.

- Q: Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q: This question asks for the current prices of aluminum coils, which may vary based on factors such as weight, thickness, and market conditions.

- <p>The prices of aluminum coils can vary significantly depending on several factors including weight, thickness, grade, and market demand. Prices are also influenced by global economic conditions and the current state of the commodities market. As of my last update, aluminum coil prices could range from a few dollars to several hundred dollars per pound, but for the most accurate and up-to-date pricing, it's best to check with a supplier or a commodities exchange, as these prices fluctuate regularly.</p>

- Q: What are the different surface treatments applied to aluminum coils?

- Some common surface treatments applied to aluminum coils include anodizing, painting, and laminating. Anodizing involves creating a protective oxide layer on the surface of the aluminum, which improves its corrosion resistance and durability. Painting can be done using various techniques such as coil coating or spray painting, providing aesthetic appeal and additional protection. Laminating involves bonding a protective film or coating onto the aluminum surface, enhancing its resistance to scratches, abrasion, and chemicals.

- Q: How do aluminum coils perform in high humidity environments?

- Aluminum coils perform well in high humidity environments due to their inherent resistance to corrosion. Unlike many other metals, such as iron or steel, aluminum does not rust when exposed to moisture. This makes it a suitable choice for applications where high humidity is a concern, such as air conditioning systems or refrigeration units. The corrosion resistance of aluminum is primarily due to the formation of a thin layer of aluminum oxide on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against further oxidation, preventing the metal from deteriorating even in humid conditions. Moreover, the lightweight nature of aluminum allows for better heat transfer and energy efficiency in cooling systems. This property makes aluminum coils a popular choice as heat exchangers, as they can effectively transfer heat from the air or fluid passing through them. Additionally, aluminum coils are typically coated with a protective layer or treated with a corrosion-resistant coating to further enhance their performance in high humidity environments. These coatings provide an extra layer of protection against moisture and other corrosive elements, ensuring the longevity and reliability of the coils. In summary, aluminum coils are highly suitable for high humidity environments due to their resistance to corrosion and their efficient heat transfer properties. The combination of these factors makes them a reliable choice for various applications where moisture is a concern.

- Q: Can aluminum coils be used in the manufacturing of window frames?

- Window frames can indeed be manufactured using aluminum coils. Aluminum is a widely favored material for producing window frames because of its multitude of benefits. It is lightweight, long-lasting, and has a natural resistance to rust and corrosion, making it applicable for both indoor and outdoor usage. In the extrusion process, which is commonly employed, aluminum coils are heated and pushed through a die to attain the desired shape and size of the window frame. This method provides manufacturers with the flexibility to create window frames in diverse styles and configurations. Moreover, aluminum is highly recyclable, rendering it an environmentally conscious option for window frame production.

Send your message to us

Mastic PVDF Coated Aluminum Coil - Mill Finished from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords