Mill Finished PVDF Coated Aluminum Composite Panels - EN AW-3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels Description

Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

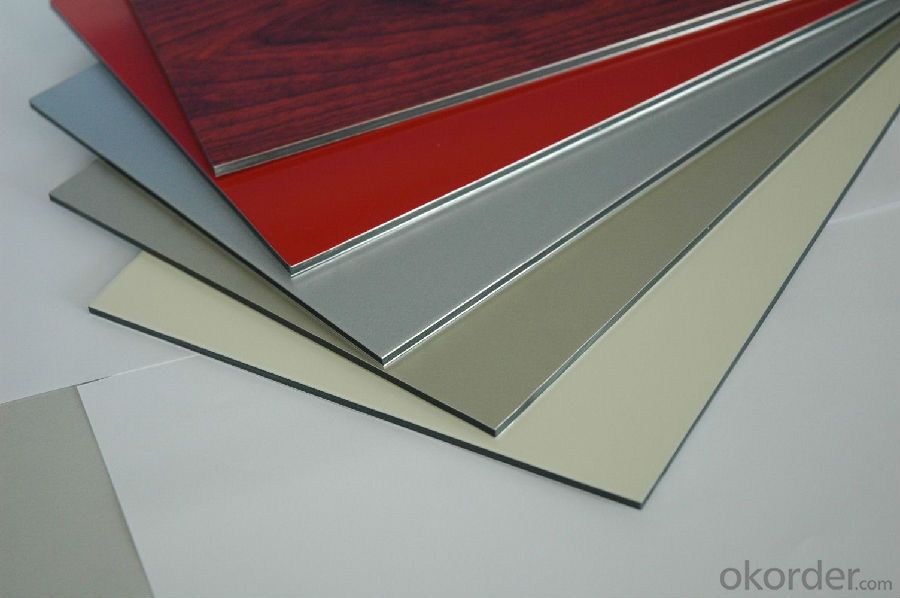

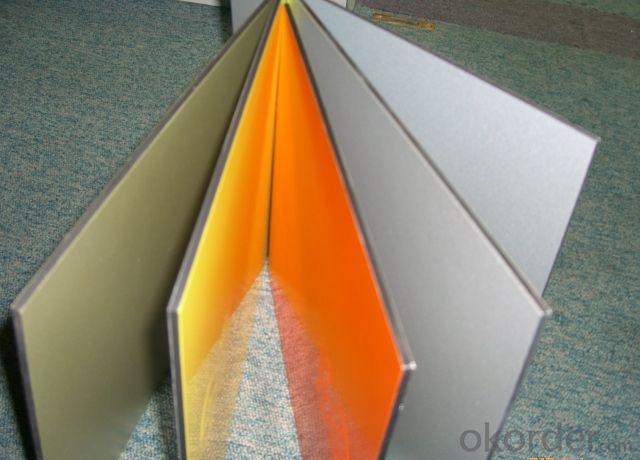

6. Image of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

7. Package and shipping of Mill Finished EN AW - 3003 PVDF Coated Aluminium Composite Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Explain how aluminum influences the propagation of sound waves.

- <p>Aluminum has a high density and stiffness, which makes it an effective conductor of sound. When sound waves hit an aluminum surface, the vibrations are quickly transmitted through the material due to its low internal damping. This results in a clear and efficient transfer of sound energy. However, aluminum's high reflectivity can also lead to a significant amount of sound being reflected rather than absorbed, which can affect the acoustics in a space, potentially causing echoes or reducing sound absorption. Additionally, aluminum's conductivity can lead to a faster decay of sound within the material, impacting the duration and quality of sound transmission.</p>

- Q: Is aluminum a suitable material for use in the electronics manufacturing industry?

- <p>Yes, aluminum is widely used in electronics manufacturing due to its excellent electrical conductivity, lightweight nature, and resistance to corrosion. It is commonly used in various electronic components such as heat sinks, capacitors, and wiring. Aluminum's malleability also allows it to be easily shaped into different forms, making it versatile for manufacturing purposes. Additionally, it is cost-effective and abundant, which further contributes to its popularity in the electronics industry.</p>

- Q: What precautions should be taken when using aluminum containers for food and beverages to ensure safety?

- <p>When using aluminum containers for food and drink, safety measures include avoiding prolonged storage of acidic or alkaline foods, as they can cause aluminum leaching. Do not heat aluminum containers in a microwave or expose them to high temperatures, as this can also lead to aluminum release. Regularly inspect containers for signs of wear or damage, as these can increase the risk of contamination. Always use food-grade aluminum containers and avoid using them for non-food items. Washing aluminum containers with mild detergents and avoiding abrasive cleaners can also help maintain their integrity and safety.</p>

- Q: Describe the melting process of aluminum, including the temperature range and any specific characteristics.

- <p>The melting process of aluminum involves heating the metal to its melting point. Pure aluminum has a melting point of approximately 660.3掳C (1220.5掳F). During the melting process, aluminum changes from a solid to a liquid state. It is important to control the temperature carefully to avoid overheating, which can lead to oxidation and the formation of dross. Aluminum is a good conductor of heat, so it heats up quickly. The melting process is often carried out in a furnace or a crucible, and protective gases like chlorine or inert gases are used to prevent oxidation. The molten aluminum is then used for various applications such as casting or welding.</p>

- Q: What are the potential dangers of utilizing high-purity aluminum powders in industrial settings?

- <p>Yes, there are risks associated with using high-purity aluminum powders in manufacturing processes. These powders can be highly reactive, especially when in fine particle form, and pose a risk of dust explosions if they come into contact with an ignition source. Additionally, aluminum dust can be a respiratory hazard, potentially causing health issues if inhaled. Proper handling, storage, and safety measures are crucial to mitigate these risks.</p>

- Q: This question asks for examples of industrial processes that incorporate the use of aluminum.

- <p>Aluminum is widely used in various industrial processes due to its lightweight, corrosion resistance, and high strength-to-weight ratio. Some key industrial processes that utilize aluminum include the automotive industry for manufacturing car parts, the aerospace industry for aircraft construction, the construction industry for building materials, the packaging industry for food and beverage cans, and the electronics industry for components in devices. Aluminum is also used in the manufacturing of machinery, electrical equipment, and transportation equipment. Its versatility makes it a crucial material in many industrial applications.</p>

- Q: Is there any health risk associated with using pure aluminum cookware?

- <p>Using pure aluminum cooking utensils is generally considered safe for most people. However, there are some concerns regarding the potential for aluminum to leach into food, especially at high temperatures or with acidic foods. While the health risks are still a subject of debate, it's recommended to use aluminum cookware with a protective coating or opt for utensils made from other materials like stainless steel or cast iron for long-term health considerations.</p>

- Q: What are some important safety measures to take when handling or working with aluminum?

- <p>When working with aluminum, it's crucial to take several safety precautions. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask to prevent inhalation of aluminum dust. Ensure good ventilation to avoid build-up of fumes, especially during welding or cutting processes. Use proper tools designed for aluminum to prevent sparks and overheating. Be aware of the fire hazard; aluminum can burn at high temperatures, so have fire extinguishers readily available. Finally, be cautious with chemicals used in aluminum processing, as they can be harmful; always follow the manufacturer's safety instructions.</p>

- Q: Explain the process by which aluminum forms alloys.

- <p>Aluminum forms alloys by combining with other elements, such as copper, magnesium, silicon, manganese, and zinc, among others. This process involves melting aluminum and the alloying elements together in a furnace. The molten mixture is then cooled and solidified to form an alloy. The resulting alloy has properties that are different from pure aluminum, such as increased strength, corrosion resistance, and improved machinability. The specific properties of the alloy depend on the elements added and their proportions. Alloying allows for the customization of aluminum's characteristics to suit various applications in industries like aerospace, automotive, and construction.</p>

- Q: Explain the impact of aluminum on the transportation system when it is incorporated into automobiles.

- <p>Aluminum has a significant impact on the transportation system when used in automobiles. It is lightweight, which improves fuel efficiency by reducing the overall weight of the vehicle. This reduction in weight leads to lower emissions, as less fuel is consumed. Aluminum's durability and resistance to corrosion also contribute to the longevity of vehicles, reducing the need for frequent repairs or replacements. Additionally, aluminum's recyclability helps in reducing waste and conserving resources, which is beneficial for environmental sustainability. Overall, the use of aluminum in automobiles enhances performance, reduces environmental impact, and promotes a more sustainable transportation system.</p>

Send your message to us

Mill Finished PVDF Coated Aluminum Composite Panels - EN AW-3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords