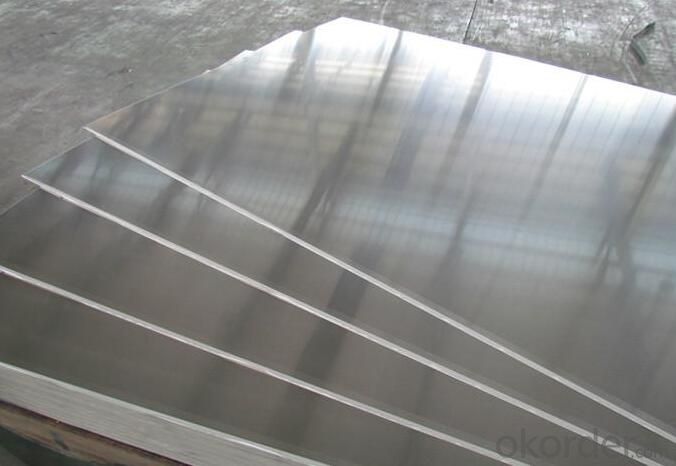

Mill Finished Diamond Plate Aluminum Sheets for Decoration Material Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finished Aluminium Plate For Decoration Material Production

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 20-30 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

PVDF color pre coated aluminum coils/ sheets:

It is well known that fluorocarbon lacquer coating (PVDF coating) owes the best acid resistant/alkali and temperature tolerant capabilities of all painting materials. Being the best quality of precoated aluminum, PVDF coated coils are especially suitable for outdoor roofing walls and ceiling manufacturing.

Polyester (PE) color pre coated aluminum coils/ sheets :

Using high-grade polyester lacquer coating material, the finished coated coils are with delicate color uniform texture, color and diverse. It is the most popular and most common used materials in decorative usage. The PE coated aluminum are widely used in ACP( aluminum composite panel ) production and indoor ceiling usage.

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: I am trying to find away of turning aluminum oxide or alumina into just aluminum. Please post all ideas i dont care how crazy.

- ensure u have distilled water cuz if there is salt in it, u might finally end up freeing chlorine interior the air and die. haha. ok, take a 9 -12 volt battery or something like that and placed 2 wires from the positve and unfavourable ends interior the water. the only cord that bubbles extra is the hydrogen. so turn a attempt tube and placed it interior the water and so as that there is not any air interior the attempt tube. whilst the cord is going in, the hydrogen will fill it up and u'll be left with organic hydrogen interior the tube. i don't be conscious of if i defined it perfect yet there are a team of video clips on youtube. examine them out.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Aluminum sheets are indeed appropriate for utilization in the food processing and packaging sectors. The food industry extensively employs aluminum due to its exceptional properties and advantages. To begin with, aluminum is a safe material for direct contact with food as it is non-toxic. It does not react with food or affect its taste, guaranteeing the preservation of the original flavor and quality. This is particularly crucial in packaging, as it aids in maintaining the freshness and integrity of the food product. Moreover, aluminum possesses excellent thermal conductivity, enabling efficient and uniform heat distribution during food processing. This attribute is advantageous in cooking, baking, and other thermal procedures, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets exhibit outstanding barrier properties, including resistance to moisture, light, and gases. This shields food from external factors that could potentially degrade its quality, such as moisture or oxygen. It also extends the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet sturdy and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and safeguards the food during transportation and storage. Lastly, aluminum is an environmentally sustainable material. It is fully recyclable, meaning it can be reused without losing its properties. This aids in reducing the environmental impact and supports the concept of a circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- in case you have coverage or can cope with to pay for to - flow see an Ear nostril Throat wellbeing care professional (additionally spoke of as otolaryngologist or ENT for short) it incredibly is the main secure and smartest element to do. maximum probable he will prescribe an ear flush for you that works o.k.. additionally, listening to in triplicate may well be a symptom of nerve inflammtion or different ailment which will properly be examined for quite truthfully by potential of a doctor. Odds are this is not something, yet extra effective risk-free than sorry.

- Q: Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Resistivity Of Aluminum Wire

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: What are the different surface patterns or textures available for aluminum sheets?

- Aluminum sheets come in various surface patterns and textures, each designed for specific purposes and offering unique aesthetic appeal. Some commonly used surface patterns for aluminum sheets are as follows: 1. Smooth: These sheets have a flat and polished surface without any visible patterns or textures. They are ideal for applications that require a clean and sleek appearance, such as architectural elements or interior design. 2. Diamond Plate: These sheets have a raised diamond pattern on the surface, providing excellent traction and slip resistance. They are commonly used for flooring, stairs, ramps, and industrial applications where grip and durability are essential. 3. Brushed: These sheets have a consistent linear pattern created by brushing the surface with fine abrasive pads. This finish gives a satin-like appearance, making it popular for decorative purposes like signs, furniture, appliances, and automotive trim. 4. Stucco: These sheets have a raised pattern that resembles a stucco wall finish. The texture is achieved by embossing the sheet with a stucco roller, creating a rough and durable surface. Stucco patterned sheets are commonly used for exterior cladding, roofing, and decorative applications. 5. Hammered: These sheets have a unique texture that resembles the surface of hammered metal. The finish is achieved by imprinting the sheet with a pattern of small indentations using a hammer or similar tool. Hammered sheets are often used for decorative purposes, such as backsplashes, countertops, and art installations. 6. Perforated: These sheets have a pattern of small holes punched into the surface, allowing for airflow, light transmission, and sound absorption. They are commonly used for architectural elements, screens, filters, and ventilation systems. These examples represent just a fraction of the surface patterns and textures available for aluminum sheets. Each texture serves a specific purpose and offers distinct visual appeal, enabling a wide range of applications in various industries.

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

Send your message to us

Mill Finished Diamond Plate Aluminum Sheets for Decoration Material Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords